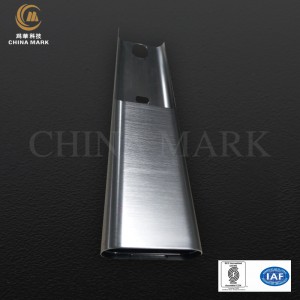

Shekaru 20 da gogewa a cikin sanadin sanyi / zane / masana'antar ƙirƙirar zafin ƙarfe na aluminium, yana mai da hankali kan buɗewar mutuwa da naushi / zane / ƙirƙira / ƙirƙirar CNC da sarrafa kayayyakin kayayyakin aluminium, ƙirar maɓallin aluminum

Aluminum extrusion na kasar Sin kimiyya da fasaha, yadu amfani, cikakken Categories, kyau kwarai ingancin, na farko-aji sabis, tasiri extrusion aluminum za a iya musamman bisa ga daban-daban bukatun, barka da zuwa shawara;

Aluminum extrusion ƙiren ƙarya extrusion tsari

I. hanyoyin aiki:

1. Zafafa silinda ingot zuwa 380 ℃ - 420 ℃ a cikin hanyar dumi danshi na 100 ℃ / 1 awa.

2. Dangane da takardar shirin aiki, zaɓi adadin da ya dace da wutar ɗumbin gidan zafin wutar aluminum zuwa 480 ℃ - 520 ℃, bayanan masana'antu na musamman bisa ga ƙayyadadden yanayin zafin jiki.

3. Dangane da tsarin aiki, zabi abin kwalliyar daidai da shirin, zafafa shi har zuwa 460 ℃ - 500 ℃, sannan a sanya shi dumi tsawan awanni 2-- 4.

4. Fara motar mai sanyaya mai wucewa - mai mai.

5. Dangane da tsari guda ɗaya na shirin, zaɓi matashi na musamman don ƙwanƙolin da za a girka a cikin ƙwanƙolin ƙira, kuma kulle ginshiƙan maɓallin a cikin yanayin extrusion.

6. Kulle ganga mai riƙewa kuma ɗaga sandar alumini mai zafi zuwa daidaitaccen matsayin gallbladder ɗin kayan ta amfani da sandar ciyarwa.

7. Jagorar silinda a gaba extrusion

8. Yakamata saurin matsawa na farko ya zama mai jinkiri, kuma matsakaicin matsakaici ya kamata a daidaita shi gwargwadon ingancin bayanan martaba a mashigar.

9. Yi rikodin lambar ƙira, lambar mashayan aluminum, matsin lamba na silinda da saurin fitarwa daki-daki a cikin rikodin asali.

Ii Bukatun aiwatarwa

1. Zafin zafin wutar sandar aluminium akan inji shine: Filayen mutuwa: 500 ℃ - 520 ℃ b. raba mutu: 480 ℃ - 500 ℃ c. kayan aikin masana'antu na musamman ana aiwatar da su gwargwadon buƙatun tsari na musamman.

2. Tsarin dumama yanayi: a. lebur mutu: 460 ℃ - 480 ℃ b. Raba ya mutu: 460 ℃ - 500 ℃

3. Kafa zafin jiki na bututu: 380 ℃ - 420 ℃ ƙarshen yanayin zafin jikin bututun ingot shine 280 ℃ - 360 ℃

4. Abubuwan da aka fitar dasu dole ne su kasance masu santsi, babu jin dadin hannu don dogon lokaci, fitarwa har ma da hatsi, babu bel mai haske, layin baƙar fata, ratar jirgin sama tsakanin jiragen sama na Yin da Yang, Kuskuren Angle, kuma Yankin Yankan ya zama mai tsayi daidaitaccen matakin bisa tsarin kasa.

5. Matsalar Extrusion: ≤200㎏ / cm2

6 matsin lamba na gall 120㎏ / cm2 - 150㎏ / cm2.

7. Zafin jiki na man hydraulic ≤45 ℃

8. Ana fitar da saurin fitar bayanan martaba gaba ɗaya a cikin: 5 m / min --30 m / min

10. Duk wani extrusion na sanduna 80 -100, dole ne yayi amfani da matashi na musamman na silinda don tsaftace bile.

Uku. Batutuwa da ke buƙatar kulawa

1. Yayin yaduwar, idan an toshe mutu, lokacin mutuwa bazai wuce dakika 5 ba.

2. Lokacin girka mollar, ka mai da hankali ga aminci kuma ka hana dunƙulen zamewa da karya ƙafa.

3. Lokacin fitarwa, an hana shi shiga kai tsaye zuwa mashiga.

4. Kafin hawa mutu, dole ne a bincika matsayin tsakiya kuma dole ne a daidaita sandar extrusion. Ya kamata a yi amfani da na'urar gwajin babu-caji sau daya kafin fara injin din.

5. Ko yawan zafin jiki na sandar aunawa, mould da ganga ya cika bukatun.

6.3 - bincika ingancin sanduna 5 sau ɗaya.

Duba yawan zafin mai.

8. Ko kowane sandar aluminium anyi alama da lambar makera da lambar yabo.