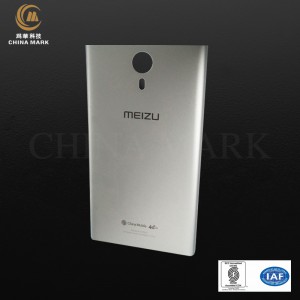

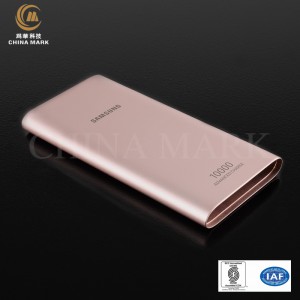

Fasahar Weihua fasaha ce ta daidaitacciyar china, tare da wadataccen ƙwarewa a daidaitaccen hatimi beaumont ca da ƙirar ƙira.

Muna tsara daidaitattun ƙwanƙwasa da ƙwanƙwasa ƙayyadaddun ƙayyadaddun samfuran samfuran gaske, kwanciyar hankali mai kyau, babban fitarwa, maraba don tuntuɓar daidaito da sabis na hatimi.

Me yakamata a lura da shi game da aikin hatimi na daidaito?

Stamp ne don latsawa da canzawa a kan farantin, tsiri, bututu da bayanin martaba da aka yi amfani da karfi na waje, don haka gurɓataccen filastik ko rabuwa, don samun siffar da ake buƙata da girman girman aikin. na kewayon girman girma, sifa mai rikitarwa da madaidaici, kuma ana amfani dasu sosai a fannoni daban daban.However, aiwatar da daidaitattun sassan sassa yana da ɗan rikitarwa. Don tabbatar da tasirin ƙirƙirar sassa, ya zama dole a kula da lamuran aiwatar da mai zuwa:

1. Adadin hanyoyin aiki na sassan hatimi na daidaito ya dogara da ƙirar fasalin tsarinta kuma ya dogara da adadin lankwasan kusurwa, matsayin dangi da kuma kwatance. Lokacin da radius ɗin lanƙwasawa na lankwasawar ya yi ƙasa da ƙimar da aka yarda, ana kara hanyar gyara bayan lankwasawa.

2. Adadin hanyoyin aiki na daidaitattun sassa na alaƙa yana da alaƙa da kaddarorin kayan abu, tsayin zane, yawan matakan zane, zanen diamita da kaurin kayan, da dai sauransu, waɗanda kawai za'a iya tantance su ta hanyar lissafin tsari. ɓangaren zane yana da ƙanƙanci ko daidaitaccen girma yana da girma, yana da mahimmanci don ƙara tsarin tsarawa bayan zane.

3. Tabbatar da yawan matakai zai kasance daidai da iya aikin gyare-gyaren da ake samu da kuma kayan aikin sha'anin sha'anin.Mo damar yin karfin aiki ya kamata ya iya tabbatar da cewa sarrafa kayan aiki, daidaiton taron daidai da bukatun ci gaba, in ba haka ba kawai don kara yawan hanyoyin.

4. Lokacin da ake buƙatar ingancin sashe da ƙimar daidaitattun sassa na daidaito ya zama mafi girma, ana iya yin la'akari da shi don ƙara tsarin sutura bayan ɓoyewa ko kuma ɗaukar madaidaiciyar hanyar ɓoye kai tsaye.

5, don inganta kwanciyar hankali na aiwatar da daidaitaccen tsari wani lokaci ana buƙatar ƙara yawan hanyoyin don tabbatar da ingancin daidaitattun sassa na alal misali.Magana ƙarin wurin lankwasa ɓangarori yayin aiwatar da huda rami, ƙirƙirar tsari na ƙara lalacewa don rage huda rami don canja wurin yankunan nakasa, da sauransu.

6, ɓoye siffar sassan sassaƙaƙƙun madaidaici, ta amfani da tsari ɗaya don kammala ginin.Blanking workpiece tare da fasali mai rikitarwa, saboda tsarin ko ƙarfin mutuwar yana iyakance, yakamata a raba shimfidar ciki da waje zuwa sassa da yawa blanking, bukatar amfani da dama stamping hanyoyin.

7, yin amfani da mai hatimi na musamman na iya inganta ingantaccen tsari, a asirce ya kawo ƙarshen man da aka yiwa fyaɗe, man inji, mai da aka sake amfani da shi da sauran kayan haɗin man da ba na musamman ba rawaya, fushin fata da sauran matsaloli.

Akwai matakan aiwatarwa da yawa na sassan hatimi na daidaito, ma'aikata ya kamata su fahimci al'amuran da ke buƙatar kula da kowane mataki daki-daki, kuma da aiwatar da ƙayyadaddun tsarin aiki.