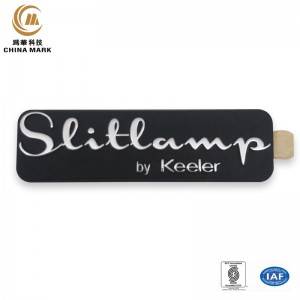

Our company specializes in the production of stainless steel nameplate etching, first-class technology and service for you to create satisfactory products!Price concessions, delivery on time!Stainless steel, engraved brass nameplate to find for China technology (custom metal nameplate factory)!

Stainless steel nameplate production process and instructions

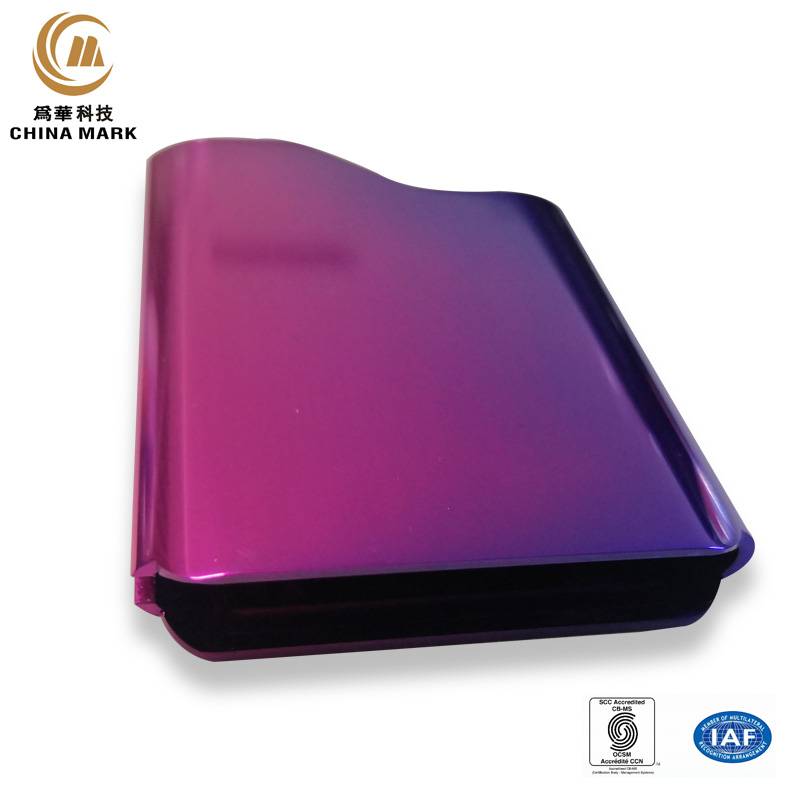

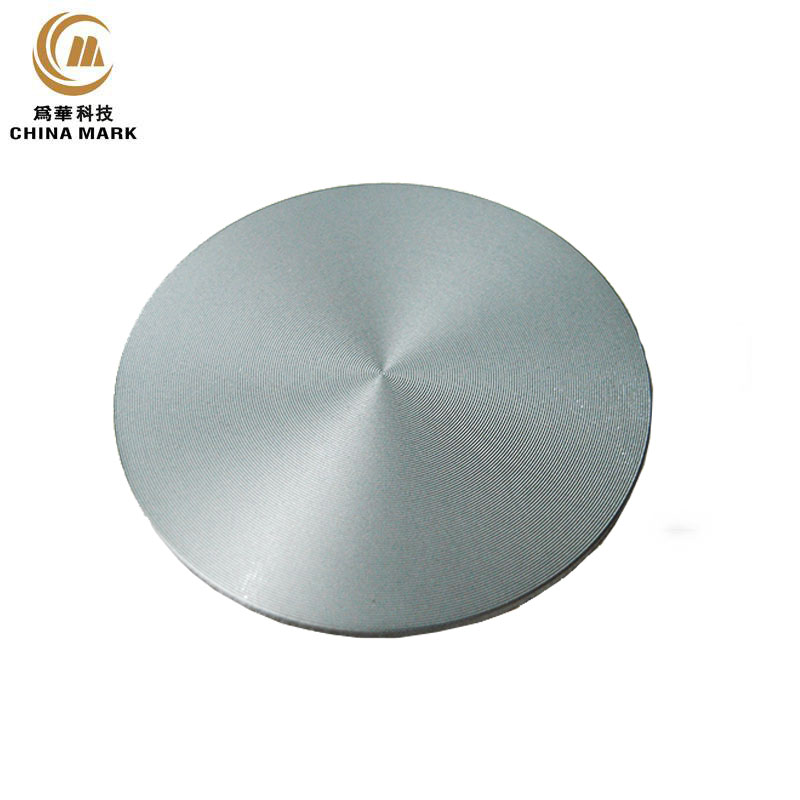

Stainless steel nameplate is to stainless steel plate as material through corrosion, screen printing and other processes into the advertising label.Generally used stainless steel nameplate is mostly made by corrosion technology, such a sign point paint with beautiful design, clear lines, appropriate depth, flat bottom, full color, wiredrawing uniform, uniform surface color and other characteristics.

Stainless steel is a kind of special material, commonly used a 201, 202, 304 stainless steel material, its production process than some copper, aluminum is difficult, but it has a good atmosphere and water medium corrosion resistance, and corrosion, after polishing, wire drawing, adornment effect is very beautiful, so the fastest for stainless steel corrosion method is also called electrochemical corrosion electrochemical corrosion.

Because the electrochemical corrosion in the plate corrosion will make the ink off, so the sign is not suitable for electrochemical corrosion, especially fine patterns.The chemical corrosion that we chose here, the main raw material for chemical corrosion here is ferric chloride;

The following is the formula for corrosion of stainless steel with ferric chloride:

Ferric chloride, active agent, water.The baume degree of ferric trichloride in the formula should be kept at about 42, adding active agent 0.8 -- 1.2 ml per liter of ferric trichloride solution.The stainless steel bottom surface corroded by this formula is smooth and clean, without black passivation film and pitting.

The factors influencing the corrosion of ferric chloride solution on stainless steel are as follows:

A. the effect of concentration.

The more positive the REDOX potential is, the faster the corrosion rate is.With the increase of concentration, the positive corrosion rate of REDOX potential change increases.Industrial grade ferric trichloride due to its purity is not high, the REDOX potential is negative, only when the baume reached above 42 REDOX potential to meet the requirements of corrosion of stainless steel.

B. Effect of PH value in solution on corrosion rate.

Low PH value, strong corrosion of stainless steel;PH over three ferric chloride hydrolysis into iron hydroxide precipitation, loss of corrosion.The PH value of the corrosion solution should be adjusted to the extent that it is used in production.

C. Influence of corrosion temperature.

The higher the temperature of the corrosion solution, the faster the corrosion rate.But in view of the resistance to corrosion ink, the temperature should be controlled in 30- 40℃ between the appropriate.

After the corrosion and then cold water clean dry, baked dry point paint color, in order to achieve color effect.After coloring, bake dry and rinse with warm water.

You may also like:nameplate for icebox;Please click to view ~