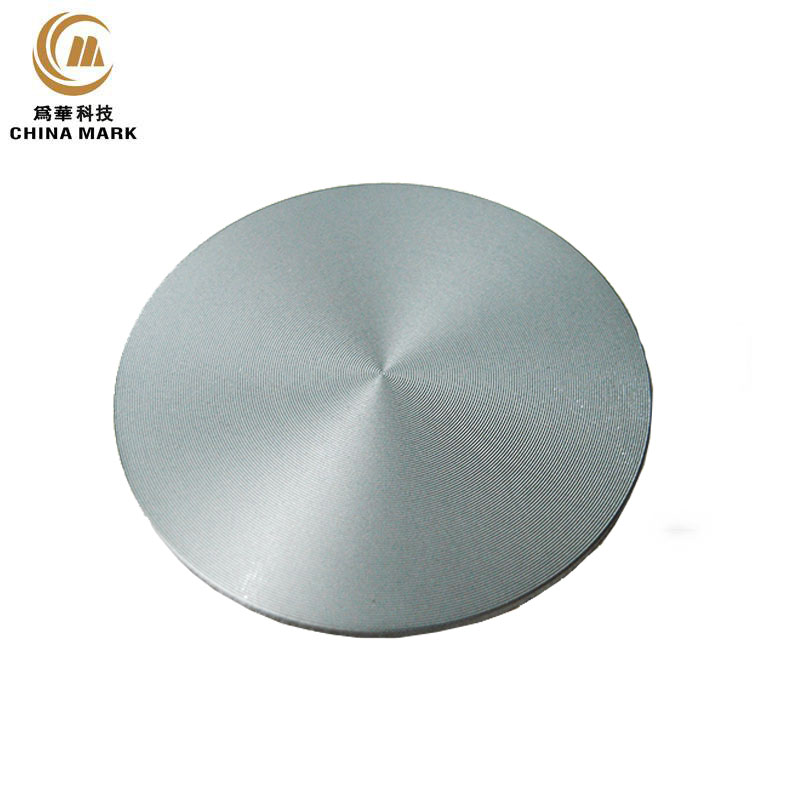

Extruded aluminum enclosure

Modern extruded aluminum housing, variable length;Extruded aluminum enclosures are especially used for high quality enclosure solution applications.Choose the design and size of the enclosure to meet your own special requirements.Extruded aluminium profiles can be supplied with special lengths on request.

All extruded aluminum enclosures provide a high degree of stability and good heat dissipation, as well as a high quality appearance.The outer shell is extruded by hollow aluminum;High strength;Adopt anodic oxidation treatment;

What should be noticed when extruding shell - like aluminum profiles?

1, choose the right extrusion machine, extrusion ratio to be reasonable.In particular, the thin - walled shell aluminum extrusion force is relatively large, extrusion ratio is very important.

2, alignment, extrusion of the aluminum profile needs to reduce the temperature below 60 degrees to straighten.Straightening when the need for stretching, stretching should also pay attention to the strength, because the aluminum profile just extrusion has no aging, relatively soft, stretching too easy to deformation.

3, drawing to choose the appropriate fixture, especially the shell of the aluminum profile, try to control the deformation in the range of 1%.Not only the fixture, there is also a relatively high level of proficiency of the workers.

4, pay attention to the ratio of width and thickness of high, long wall, radian, wall thickness of the big difference in size, strange shape and other profiles of small feet, thin teeth, long legs, arc, inclined plane, opening, point of view, etc., to avoid aluminum section or point scale deformation, twist, screw and other shortcomings.

5, because the wool has the effect of heat resistance, so just out of the aluminum section in the cooling process needs to often turn, to avoid uneven cooling caused by local bright spot, especially large section, thick wall aluminum section.

6, when taking materials and moving to pay attention to prevent rubbing, each material to leave a gap between each layer of material to be separated by wool.The bending and the length of the aluminum profile to be timely treatment.