Now, we will share the types of materials that we will popularize the signs.

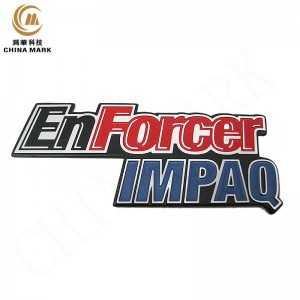

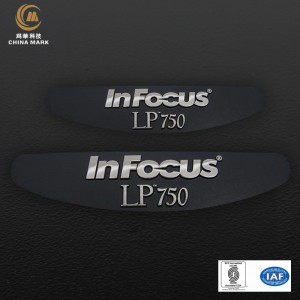

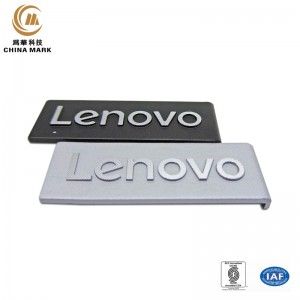

1. Metal signs

In the signage industry, commonly used metals include aluminum, aluminum alloy, stainless steel, iron, copper, brass, nickel, etc. Among them, materials such as stainless steel and galvanized sheet have high strength, long service life, and can be welded. Metal signs are mostly the materials of choice for large outdoor signs. Commonly used processes include stamping, forging, polishing, polishing, sandblasting, electroplating, oxidation, silk screen printing, engraved and die casting. Metal signs are currently the most common sign products of sign manufacturers.

2. Wooden signs

The wood commonly used in the sign industry mainly includes natural mahogany and imitation mahogany.

The natural mahogany wood floor is excellent, hard and durable, the texture is calm and beautiful. Commonly used mahogany in China are chicken branch wood, rosewood, rosewood, and fragrant mahogany. Mahogany is a precious wood. Because of its high price, it is generally used in a narrow range and is only used in some top hotels and clubs. In the sign industry, imitation mahogany is the most widely used. Imitation mahogany is easier to buy, carving and post-processing are also more convenient, and its decorative effect can also be comparable to natural wood.

Although other ordinary woods are low in cost, they are susceptible to deformation and cracking due to natural factors.

3.stone signs

Stone has a long history like the use of wood. It is not easily damaged by natural conditions and has a long service life. The biggest disadvantage is that the material itself is too heavy, which is not conducive to processing, and there are more structural considerations. The commonly used material for signs is marble. Although natural stone has rich surface texture and bright color, it is difficult to cut and engrave, so it is rarely used in the sign industry. Artificial marble has a lifelike natural appearance, light texture, easy molding, easy installation, and rich colors, so it is widely used in the sign industry.

4. acrylic signs

Acrylic material, it has high transparency, has the reputation of "plastic crystal". It is also widely used because of its easy processing and the characteristics of crystal clear, light weight and toughness. Acrylic processing technology generally includes screen printing and engraving. Acrylic is generally used in combination with stainless steel, marble, and two-color plates.

5. plastic signs

Plastic signs are generally made of plastic materials and screen printed. It can also be combined with stainless steel, titanium plate and sand gold surface through etching, silk screen, paint filling and other processes. The biggest feature of this type of sign is low price, mass production, emphasizing commonality and diminishing individuality. Mainly used in small hotels or guesthouses to highlight its functional applications.

If you want to get creative and modern signs, please feel free to contact us. Specializing in the production of custom signs, we are definitely the manufacturer you have been looking for.