Extruded aluminum is one of the most popular and cost-effective ways to manufacture radiators.Standard extrusion radiators are pre-cut and finished radiators and usually include installation hardware.Standard extruder radiators include finished flat backs with clearance on both sides usually used for plate-level cooling.

Aluminum extruded radiators can range from simple flat back finned structures to complex geometries used to optimize cooling.Alloys 6063 and 6061 are the most commonly used aluminum alloys with high thermal conductivity.

If you need a customized aluminum extrusion radiator, we can work with you to design a customized extrusion solution to meet your specific needs.Weihua co., LTD. Cooperates with top aluminum profile manufacturers who have many years of experience in product production.

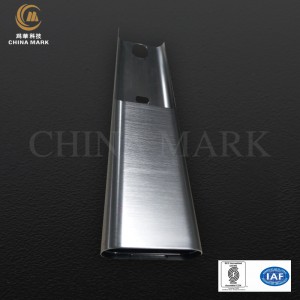

Custom extrusion radiator machining

If you have designed fins, we can help you to make them.Can provide you with the required alloy, surface finish and secondary processing.

1. Alloy selection

The aluminum alloys in the 6000 series have excellent thermal conductivity, are widely used and are fairly strong.They also tend to crowd out well.The most commonly used alloys for extrusion radiators are 6061 and 6063.Our partner extrusion equipment can extrude these alloys or the alloys of your choice.

2. Surface treatment

One of the most common surface treatments for radiators is anodizing.This electrochemical process improves surface emissivity, corrosion resistance, wear resistance and electrical insulation.

Radiators can be anodized with colored dyes in our extrusion equipment.

3. Post-processing

The way to maximize the surface area of the extrusion radiator is through transverse milling after extrusion.CNC machining is a very precise method of converting the heat sink on an extruded heat sink into a pin.Helps to maximize heat dissipation, thereby making radiators more efficient.In addition, we can perform other auxiliary operations, such as drilling, stamping and cutting.

Aluminum extrusion radiator characteristics

1、Aluminum profiles are the most cost-effective solution for most electronic cooling applications

2、Made of 6063 aluminum alloy

3、Certified as lead-free

4、Extruded profiles can be used in straight fin, star LED and linear LED designs to ensure maximum performance for specific thermal applications