Aluminum Heatsink For LED Light | WEIHUA

What are the different types of heat sink?

Almost all materials used for heat sinks on the market are aluminum or copper.

Below I will explain the difference between the different aluminum heat sink material radiators briefly:

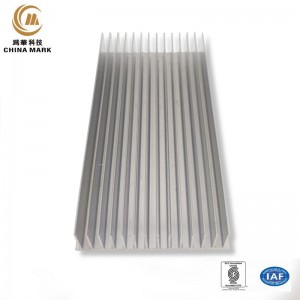

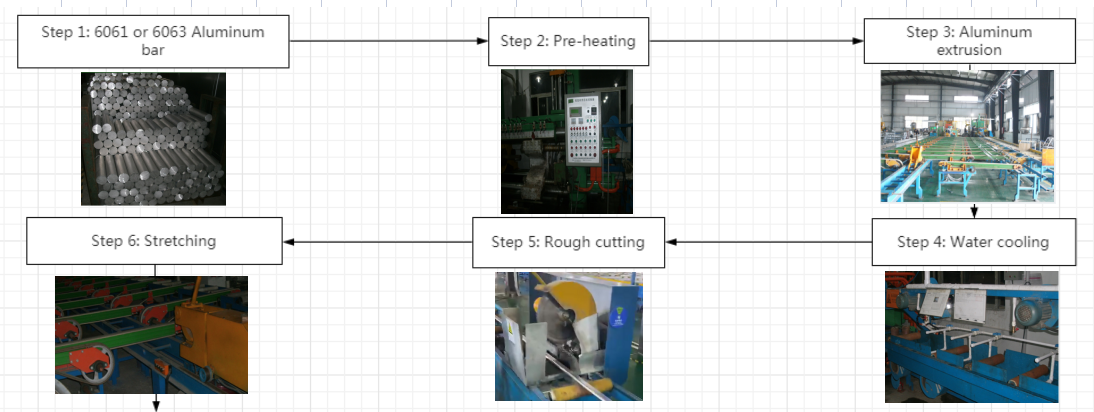

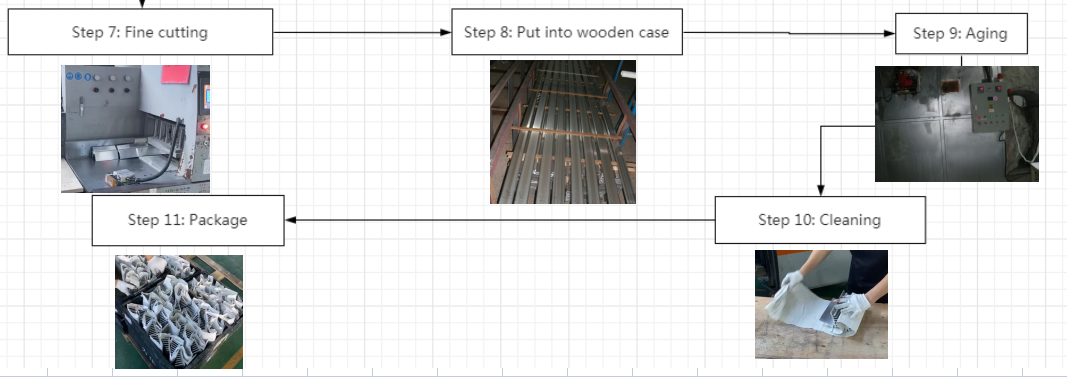

(1) Extruded aluminum heat sink

Mainly made of 6061-T5/T6 or 6063-T5/T6 materials, these two kinds of materials are medium-strength aluminum alloys, whether it is corrosion resistance, weldability, processing performance are relatively good, and easy to polish, It can achieve a good anodizing effect, which is a typical radiator extruded alloy material. The radiator made of this material has the advantages of strong thermal conductivity, fast heat dissipation, low cost, and short delivery cycle.

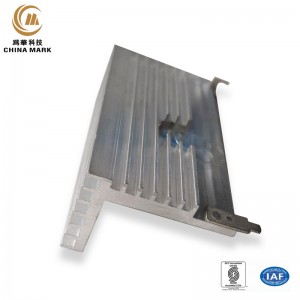

(2) Cold forging/hot forging heat sink

It is made of 1070 aluminum plate or 1060 aluminum plate, which has high plasticity, corrosion resistance, electrical conductivity and thermal conductivity. The radiator made of this material generally has a simpler appearance and fast heat dissipation, but the unit price of the material is higher, so the cost is higher than that of an aluminum extruded radiator.

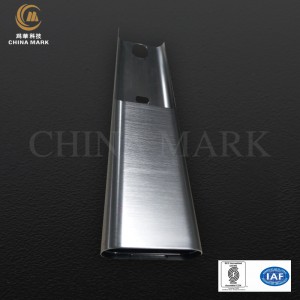

(3) Die-cast aluminum heat sink

Usually made of ADC12 material, ADC is Aluminum-Alloy Die Castings, which is a Japanese aluminum alloy grade, also known as No. 12 aluminum, Al-Si-Cu series alloy, which is a die-cast aluminum alloy. The radiator made of this material can adapt to a variety of complex shapes, but it cannot be completed by anodizing, and can only be made by painting or electroplating.

(4) Copper heatsink

Unless it is a high-end product that needs to improve performance, it will choose to use copper radiator. Because compared to aluminum radiators, copper is three times the weight of aluminum, and at the same time, the cost is more than twice that of aluminum, but the heat dissipation capacity is not as strong as aluminum. Unless it is an all-copper radiator, it will dissipate heat much faster than aluminum

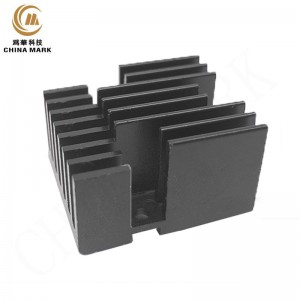

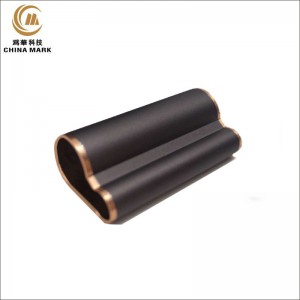

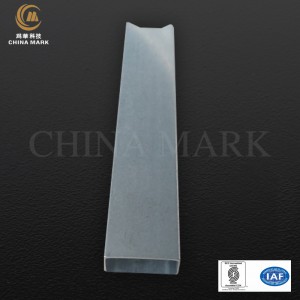

Aluminum Heatsink For LED Light

Product Description:

Product Name: |

Aluminum Heatsink For LED Light |

Material: |

AL 6061 or AL 6063 |

Specification: |

78x78 mm |

Color: |

Clear Anodized or Black Anodized or other colors you want |

Main Process: |

Aluminum extrusion+Anodized/Sandblasting |

Free Sample: |

Yes |

Sample Time: |

1-2 weeks |

Lead Time: |

1-2 weeks |

The main process are as below

To learn more, please see below vedio of this black painting heatsink.

You may also like these below heatsink

GIVE US A CALL

If you're interested in this review and want to know more about the details, or you need any other helps, please find our contact below.

AVAILABLE AT 9AM TO 6PM

0086+19926691505

Write your message here and send it to us