Led Heat Sink Design From Factory | WEIHUA

Which led heat sink design guide is best?

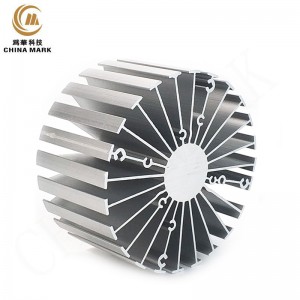

A. Cold forging/hot forging integrated heatsink:

(1) Usually made of 1070 or 1060 pure aluminum, with less impurities and higher unit price of materials

(2) High heat conduction and heat dissipation performance, integrated structure

(3) The mold opening cycle is 2-3 weeks, and the mold price is in the middle

(4) It can be sandblasted and anodized to make all kinds of colors you want

(5) Suitable for heat sink in led bulb with simple appearance and large product consumption

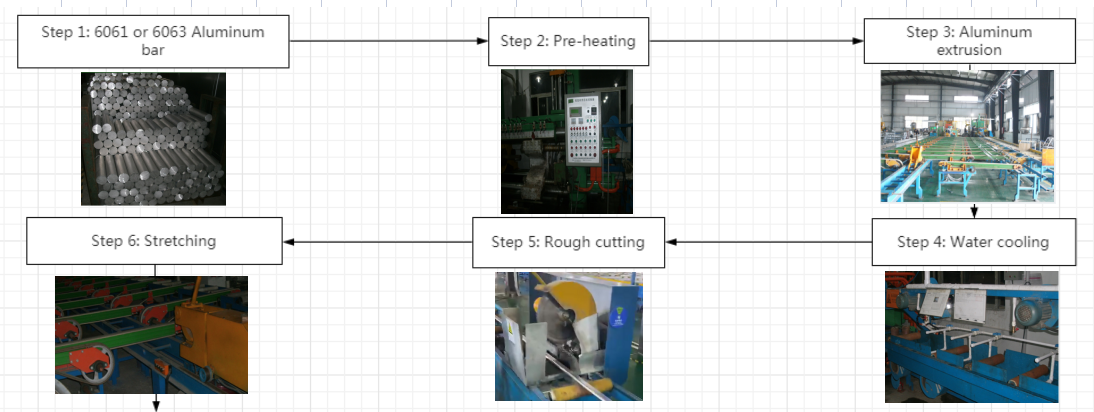

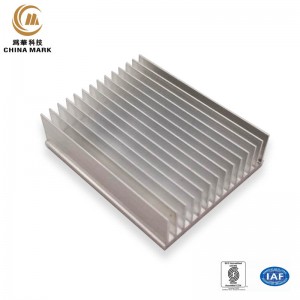

B. Aluminum diy led heat sink:

(1) 6061 or 6063 aluminum is usually used, and the unit price of the material is cheaper than 1070/1060 aluminum

(2) General thermal conductivity, uneven heat transfer, split structure

(3) The mold opening cycle is 1-2 weeks, and the mold price is the lowest

(4) It can be sandblasted and anodized to make all kinds of colors you want

(5) Suitable for LED lamps or other products with general appearance and general product usage

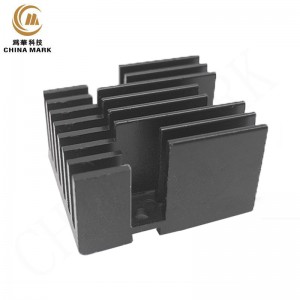

C. Die-cast aluminum heatsink:

(1) ADC12 die-cast aluminum is usually used, and the material is cheaper than the first four

(2) Poor thermal conductivity

(3) The mold opening cycle is 4-5 weeks, and the mold price is the highest

(4) No sandblasting anode can be used, only electroplating or painting treatment

(5) Suitable for high-power and complex-shaped LED lamps

It can be concluded that the best led lamp heat sink design is cold forged/hot forged heatsink, followed by aluminum heatsink.

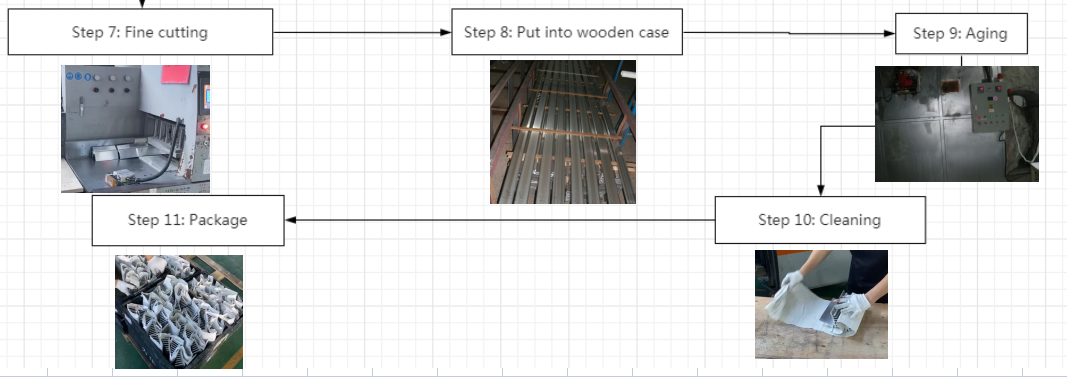

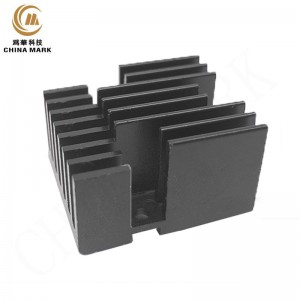

Led Heat Sink Design From Factory

Product Description:

Product Name: |

Led Heat Sink Design From Factory |

Material: |

Aluminum 1070/Aluminum 1060 |

Specification: |

180×90 mm or customized size |

Main Process: |

Hot Forging+CNC |

Surface Finishing: |

Sandblasting+Anodizing |

Package: |

Carton & Blister & Foam |

Sample Time: |

1-2 weeks |

Lead Time: |

1-2 weeks |

The main process are as below: