Heatsink Manufacturer,Hot Forging Heat Sink Supplier | WEIHUA

Why are most of them aluminum heatsinks instead of copper heatsinks?

-

Storage capacity: The storage capacity of copper is insufficient, and imports are needed to meet the production of copper heatsinks. Therefore, the price of copper heatsinks is relatively high, which is not conducive to the production of copper heatsinks. The content of aluminum in the earth's crust is very high, and energy storage is abundant.

-

The density of copper is 8.9gcm3, and the density of aluminum is 27gcm3. Therefore, under the same size, the weight of copper is 2/3 heavier than aluminum, and the price is also more expensive than aluminum. This also makes more businesses prefer aluminum, because The weight is light, and the freight is relatively small.

-

Service life: the service life of aluminum heat sink is 7 years; while the service life of copper heat sink is only 5 years

-

Aluminum is a good conductor of heat, its thermal conductivity coefficient is 167W/m.K, and the thermal conductivity coefficient of steel is 50W/m.K. The larger the value, the higher the thermal conductivity. Therefore, compared to aluminum and steel, everyone will give priority to aluminum heatsinks.

-

Because of the dense oxide protective film on the surface of aluminum, it is not easy to be corroded.

-

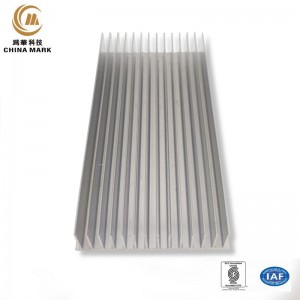

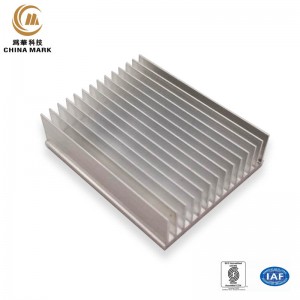

Aluminum heatsink has the characteristics of strong decorative appearance, sturdy and durable, light weight, good anode treatment performance, excellent surface treatment performance, good metal thermal strength, good heat dissipation performance, and good energy saving and environmental protection effects.

-

Aluminum heatsinks are widely used in industries such as machinery, automobiles, wind power generation, construction machinery, air compressors, railway locomotives, household appliances, etc. due to their superior performance.

Therefore, in general, the heatsink made of aluminum alloy is superior to the heatsink made of other materials in any respect.

And we are also heatsink manufacturer in China, custom heat sink manufacturer, pin fin heatsink manufacturer, aluminum heat sink manufacturer in china and cnc heat sink manufacturer. Welcome to consult more questions about radiators.

Heatsink Manufacture,Hot Forging Heat Sink Supplier

Product Description:

Product Name: |

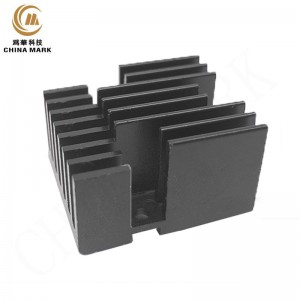

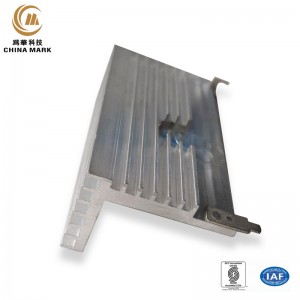

Aluminum Heatsink,Aluminum Hot Forging Supplier |

Material: |

Aluminum 1070/Aluminum 1060 |

Specification: |

Customized size |

Process: |

Hot Forging+CNC |

Surface Finishing: |

Sandblasting+Anodizing |

Package: |

Carton & Blister & Foam |

Sample Time: |

1-2 weeks |

Lead Time: |

1-2 weeks |

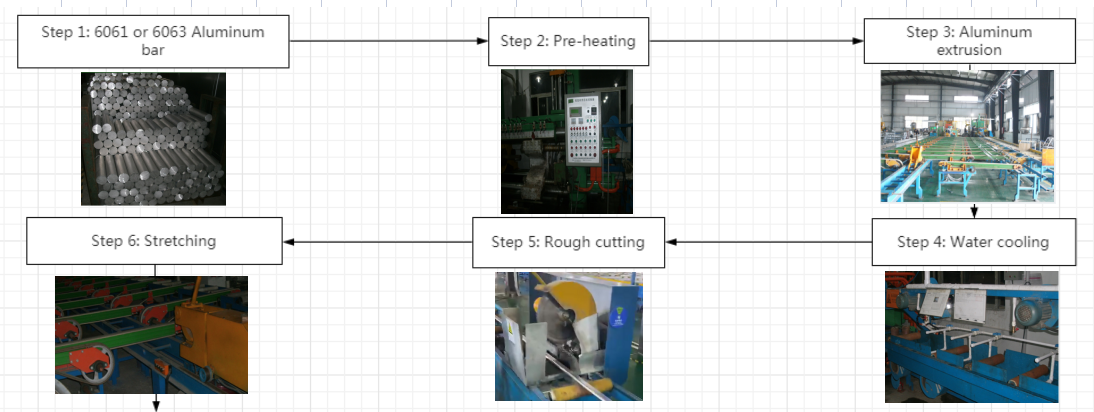

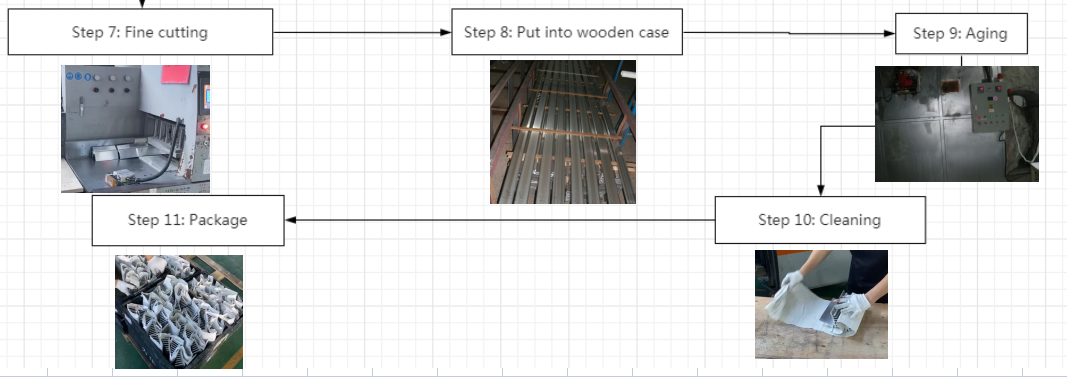

The main process are as below:

To learn more, please see below vedio of this black painting heatsink.

You may also like these below heatsink

GIVE US A CALL

If you're interested in this review and want to know more about the details, or you need any other helps, please find our contact below.

AVAILABLE AT 9AM TO 6PM

0086+19926691505

Write your message here and send it to us