Electroforming is a labelling technique that allows high quality, detailed products to be created with the use of a metallic solution. Placing a mould into the electrically charged current causes a build up of particles, which over time bind together to form the badge, label or nameplate.

Electroformed Badges

This advanced exterior and interior branding solution produces electroformed nameplates and badges with incredibly fine detail, while maintaining an impressive level of durability.

Features

1、Every finishing such as sandblast, hairline, gloss can express the precision of genuine metal surface which plated plastic can never get. In comparison with other production methods, electroforming can realize the outstanding sharpness of edge lines.

2、Electroforming nameplates are made by Nickel which has high adhesiveness of plating while plating on plastic requires very special treatment for background. As the plating on Nickel has high adhesiveness and it is stable, there is no risk of plating peeling off. For plating, Chrome, Gold, Rhodium, Rhutenium etc. are available.

3、There is no difference between prototype and production part since the electroforming is replica technology. For this reason, variation in appearance among the products is quite tiny. It is very fitted for the design which requires the metal texture and precision.

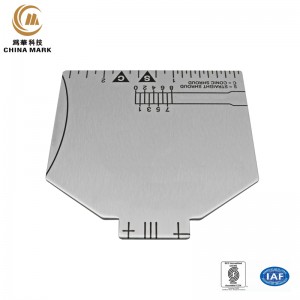

Custom manufacturer of electroformed nameplates

Fabricated from flexible or metal materials such as aluminum, brass, and stainless steel. Designed to withstand up to 25 years of outdoor exposure. Custom manufacturer of electroformed and etched nameplates. Materials used include aluminum alloys, beryllium copper, brass, carbon steel, copper and copper alloys, nickel and nickel alloys, phosphorous bronze, silver nickel, spring steel and stainless steel. Capabilities include designing, engineering, photochemical machining/photochemical milling, prototyping and mechanical, design and system level assembly.

You may also like:nameplate for icebox;Please click to view ~

People also ask

1、How to make metal etch nameplate?

2、how to buy metal for name plates