Aluminium extrusion maitiro

Iyo aruminiyamu chiwanikwa extrusion maitiro anotanga neyakagadzirwa dhizaini, nekuti chigadzirwa dhizaini chinoenderana nezvinopihwa mashandisiro ekushandisa, ayo anoona akawanda ekupedzisira paramende echigadzirwa.Sakadai sechigadzirwa chinogadzira michina yekugadzirisa kuita, kwepamusoro kurapwa mashandiro uye kushandiswa kwezvakatipoteredza zvinodiwa , izvi zvivakwa uye zvinodiwa zvinonyatso sarudza sarudzo ye extruded aluminium alloy.

Nekudaro, izvo zvivakwa zvealuminium yakatsikwa yakatarwa neyakagadzirwa dhizaini yechigadzirwa. Chimiro chechigadzirwa chinogadza chimiro cheiyo extrusion kufa.

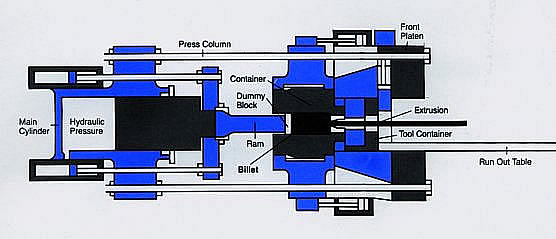

Paakangogadzirisa dambudziko dhizaini, iyo inoshanda extrusion maitiro ari kutanga extrusion yakakandwa mualuminium tsvimbo, aruminiyamu yekukanda tsvimbo inofanira kudziyirwa pamberi pekunze kuti iinyorove, iyo yekudziya yakanaka aruminiyamu yekukanda tsvimbo sheng ingot inoiswa mune yekuwedzera dhiramu mukati, uyezve nepamusoro simba hydraulic cylinder kusundira extrusion tsvimbo, kumberi kwekupedzisira kweiyo extrusion tsvimbo ine yekumanikidza pad, yakadaro inopisa yakapfava aluminium alloy mune dummy block pasi yakasimba kumanikidzwa kubva kuforoma chaiyo kuumbwa extrusion kuumbwa.

Izvi ndizvo zvinoitwa neforoma: chimiro chechigadzirwa chinodiwa mukugadzira.

Mufananidzo wacho ndewe: chaiwo akatwasuka hydraulic extruder schematic diagram

Iwo mafambiro e extrusion akasara kurudyi

Iyi ndiyo rondedzero yakapusa yeakanyanya kushandiswa kwakanyanya extrusion nhasi. Kunanga kusinganzwisisike kuita kwakafanana, asi kune mamwe misiyano yakakosha.

Mune iyo isina kunangana extrusion process.Iyo yakaiswa pane isina mhango extrusion bar, kuitira kuti iyofa ikamanikidzwa yakananga kune isingazungunuke aluminium bha isina chinhu, ichimanikidza iyo aruminiyamu chiwanikwa kuti chibudise chakananga kune isina mhango extrusion bar kuburikidza nefa.

Muchokwadi, iyo extrusion maitiro yakafanana nekusvina mushonga wemazino. Kana iko kumanikidza kunoiswa kumagumo akavharwa emushonga wemazino, mushonga wezino wesirinda unosvinwa kuburikidza nekuvhurwa kwedenderedzwa.

Kana mukova wacho wakatsetseka, mushonga wemazino wakasvinwa unobuda seribhoni.

Ehe, maumbirwo akaomarara anogonawo kusvinirwa kunze pakuvhurika kwechimiro chakafanana Semuenzaniso, vagadziri vekeke vanoshandisa zvakaumbwa zvakaumbwa machubhu kusvina ice cream kugadzira mhando dzese dzefrills.

Kunyange iwe usingakwanise kugadzira zvigadzirwa zvakawanda zvine mushonga wemazino kana ice cream, haugone kusvina aluminium mumachubhu neminwe yako.

Asi iwe unogona kushandisa yakasimba hydraulic muchina kuburitsa aluminium kubva kune yakapihwa fomu yeforoma kuburitsa akasiyana siyana anobatsira zvigadzirwa zveanenge chero chimiro.

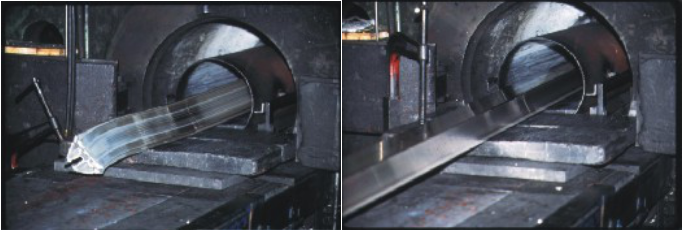

Mufananidzo uri pazasi (kuruboshwe) unoratidza chikamu chekutanga chemudhara pakutanga kwekuburitsa. (rudyi)

Bhawa

Iyo aluminium bar ndiyo isina chinhu yeiyo extrusion maitiro. Iyo aruminiyamu bhaa inoshandiswa kuburitsa inogona kuve yakasimba kana isina mhango, kazhinji cylindrical, uye kureba kwayo kunoonekwa neiyo extrusion chubhu.

Aluminium tsvimbo dzinowanzo kuumbwa nekukanda, kana nekugadzira kana poda yekugezera.Iyo inowanzoitwa nekucheka aluminium alloy mabara ane yakanaka alloy kuumbwa.

Aluminium alloys anowanzo kuve akaumbwa zvinopfuura imwechete yesimbi element. Yakawedzeredzwa aluminium alloys inoumbwa ne trace (kazhinji isingapfuure 5%) zvinhu (senge mhangura, magnesium, silicon, manganese, kana zinc) izvo zvinovandudza zvivakwa zve pure aluminium uye zvinokanganisa iyo extrusion maitiro.

Kureba kwearuminiyamu tsvimbo kunosiyana kubva kumugadziri kuenda kumugadziri, inoonekwa nehurefu hunodiwa hwekupedzisira, chiyero che extrusion, kuregedza kureba uye mvumo yekuwedzera.

Hurefu hwakareba kazhinji hunowanzo kubva pamasendimita makumi matanhatu (660mm) kusvika pamasendimita 72 (1830mm) Kunze kwemadimitha anotangira pamasendimita matatu (76mm) kusvika 33 inches (838mm), 6 inches (155 mm) kusvika 9 inches (228 mm).

Kutungamira extrusion maitiro

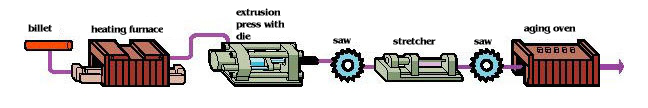

[billet] [kudziyisa mudziyo] [extrusion muchina nefa] saw [strecher] [kuchembera overn]

Iyo dhayagiramu inoratidza matanho ekutanga ekuburitsa aruminiyamu bar

Kana yekupedzisira chigadzirwa chigadzirwa chakatemwa, yakakodzera aruminiyamu chiwanikwa inosarudzwa, iyo extrusion kufa kugadzirwa kwapera, uye kugadzirira kweiyo chaiyo extrusion maitiro apera.

Wobva watangisa preheat iyo aluminium bar uye yekuwedzera extrusion Munguva ye extrusion maitiro, iyo aruminiyamu bhaa yakasimba, asi yakanyoroveswa muvira.

Iyo yakanyunguduka poindi yealuminium alloy ingangoita 660 ℃ .Iyo chaiyo kupisa tembiricha yeiyo extrusion maitiro inowanzo kuve yakakura kupfuura 375 ℃ uye inogona kuve yakakwira se500 ℃, zvichienderana nemamiriro ekunze kwesimbi.

Iyo chaiyo extrusion maitiro inotanga apo iyo extrusion tsvimbo inotanga kuisa kumanikidza kune yealuminiamu tsvimbo mune ingot.

Mhando dzakasiyana dzemuchina wekudhinda dzakagadzirirwa kusvina chero kubva pamatani zana kusvika ku15,000 matani.Iyi extrusion kumanikidza inotarisa saizi yeiyo extrusion inogadzirwa neiyo extrusion muchina.

Yakawedzerwa chigadzirwa magadzirirwo anoratidzwa nehupamhi hwechikamu chemuchinjikwa chikamu chechigadzirwa, dzimwe nguva zvakare neakakomberedza dhayamita yechigadzirwa.

Kana iyo extrusion ichangotanga, iyo aruminiyamu bhaa inoiswa kune yekuita simba rechimiro uye inova ipfupi uye mukobvu, kudzamara kuwedzera kwealuminium bar kunorambidzwa neiyo ingot barrel wall;

Zvino, apo kumanikidza kuri kuramba kuchikura, iyo yakapfava (ichiri yakasimba) simbi haina nzvimbo yekuyerera uye inotanga kusvinhwa kubva mugomba rekuumbika ichienda kune mumwe mugumo weforoma, ichiumba chimiro.

Inenge gumi muzana yesimbi yealuminium (kusanganisira aruminiyamu tsvimbo yeganda) inosara iri muingot barrel, chigadzirwa che extrusion chinotemwa kubva muforoma, uye simbi yakasara iri mudhiramu yeinot inocheneswa uye kushandiswazve. iyo inotevera maitiro ndeyekuti iyo inopisa extrusion chigadzirwa inodzimwa, michina uye yakura.

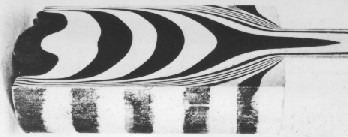

Kana iyo aluminium inopisa ikabuditswa kubva muforoma kuburikidza neye ingot cylinder, simbi iri pakati pebhawa yealuminium inoyerera nekukurumidza kupfuura kumucheto.Sekuti mutsetse mutema uri mumufananidzo unoratidza, simbi yakatenderedza micheto inosara kumashure kuti idzokororwe se vakasara.

Chiyero che extrusion chinoenderana nesimbi iri kusvinwa uye chimiro chegomba rekufa. Uchishandisa zvakaoma chiwanikwa kusvina yakaoma chakaumbwa zvinhu zvinogona kunge zvichinonoka kunge 1-2 tsoka paminiti.Ne zvinyoro alloys, akareruka maumbirwo anogona kusvinwa kusvika 180 tsoka paminiti kana kupfuura.

Kureba kwechigadzirwa che extrusion kunoenderana nealuminium bar uye iyo gomba yekuburitsa gomba. Kuenderera mberi extrusion kunogona kuburitsa chigadzirwa kusvika pamamita mazana maviri. Iyo yazvino kuumbwa extrusion, kana icho chakaburitswa chigadzirwa chinosiya iyo extruder inoiswa pane iyo slide (yakaenzana nebhandi rekutakura);

Zvinoenderana neakasiyana chiwanikwa, kuburitswa kunze kwechigadzirwa kutonhora maitiro: akapatsanurwa kuita kwechisikirwo kutonhorera, mweya kana kutonhora kwemvura asi kudzima.Iyi inhanho yakakosha yekuona iko metallographic kuita kwechigadzirwa mushure mekukwegura. Icho chakaburitswa chigadzirwa chinobva chaendeswa kune mubhedha unotonhora.

Ruramisa

Mushure mekudzima (kutonhora), chigadzirwa chakaburitswa chakatwasanudzwa uye chakatwasanudzwa nekutambanudza kana kutwasanudza (kutambanudza kunoiswawo muchando sekushanda mushure mekuwedzera) Pakupedzisira, chigadzirwa chinoendeswa kumuchina wekucheka nemuchina wekuburitsa.

Kucheka

Chaicho chakapedzwa chigadzirwa kucheka ndiko kucheka kwechigadzirwa kune yakatarwa yekutengesa kureba. Masenduru macheka ndiwo anoshandiswa zvakanyanya nhasi, kunge rotary ruoko masaha anotema zvidimbu marefu zvezvinhu zvakabuditswa zvichisimuka.

Kune mamwe zvakare macheka akachekwa kubva kumusoro kweprofile (senge yemagetsi matare saw) Zvakare zvinobatsira saha tafura, saw tafura ine disc disc saw blade kubva kuzasi kumusoro kucheka chigadzirwa, uyezve iyo saw saw blade kudzokera kuzasi yetafura yeiyo inotevera kutenderera.

Yakajairwa yakapera denderedzwa saw ine 16-20 inches muhupamhi uye ine anopfuura zana zana macarbide mazino. Makuru akaona mashizha anoshandiswa kune akakura dhayamita extruders.

Iyo yekuzvidzora-yekucheka michina yakagadzirirwa nehurongwa hunounza mafuta kune iyo sawtooth kuverengera optimum sawing kunyatsoshanda uye nepamusoro pesaha.

Muchina wekutsikirira unobata zvikamu munzvimbo yekucheka uye marara ekucheka anounganidzwa kuti ashandiswe zvakare.

Kukwegura:

Zvimwe zvigadzirwa zvakabuditswa zvinoda kuchembera kuti zviwane simba rakakwana, saka zvinonziwo kuchembera. Kukwegura kwemasikirwo kunoitwa patembiricha yekunze. Kukwegura kwekugadzira kunoitwa muchoto chekweguru. Nehunyanzvi, inonzi kunaya kwakanyanya chikamu kupisa kupisa.

Kana iyo profil ikabuditswa kubva kune iyo extruder, iyo mbiri inova semi-solid Asi ihwo hunokurumidza kuva hwakasimba kana hwakatonhorera kana kudzimwa (ingave mweya-watonhorera kana mvura-yakatonhorera).

Isiri-kupisa inorapwa aluminium alloys (senge aluminium alloys ine yakawedzera magnesium kana manganese) inosimbiswa neyakaitika kukwegura uye kutonhora kushanda. Heat inorapika aluminium alloy (yakadai sealuminium alloy nemhangura, zinc, magnesium + nesilicon) inogona kuwana simba riri nani uye kuomarara. nekukanganisa kurapwa kwekushisa kweiyo alloy metallographic chimiro.

Uye zvakare, kukwegura kuita kuti zvidimbu zvechikamu chakasimbiswa zvakaenzana zvakapatsanurwa kuwana iyo yakawanda goho simba, kuomarara uye kuomarara kweiyo yakakosha chiwanikwa.

Bales

Kunyangwe kuchembera chiravira kana tembiricha tembiricha kuchembera, mushure mekuzara kuchembera, iyo mbiri inoendeswa kune yekurapa kwepamusoro kana yakadzika yekugadzirisa musangano kana mabhero akagadzirira kutakura kuenda kumutengi.

Vanhu vanobvunzawo

Post nguva: Mar-20-2020