Aluminium txheej txheem txheej txheem txheej txheem

Aluminium alloy extrusion txheej txheem ua tau pib nrog cov khoom tsim, vim hais tias cov khoom tsim yog raws cov kev siv cov khoom siv, uas txiav txim siab ntau yam kev txiav txim siab kawg ntawm cov khoom.Xim li cov khoom lag luam kev ua tiav kev ua haujlwm, kev kho deg thiab kev siv ib puag ncig , cov khoom no thiab qhov yuav tsum tau txiav txim siab xaiv qhov tseeb ntawm extruded aluminium alloy.

Txawm li cas los xij, cov khoom ntawm extruded aluminium yog txiav txim siab los ntawm tus qauv tsim ntawm cov khoom.Qhov duab ntawm cov khoom txiav txim siab qhov zoo li ntawm extrusion tuag.

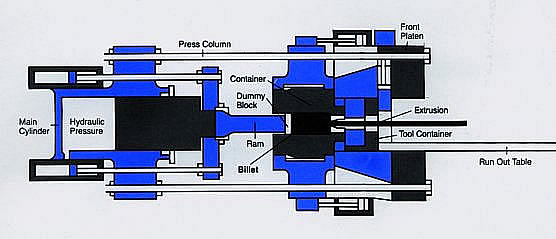

Thaum daws qhov teeb meem tsim, cov tswv yim extrusion txheej txheem pib extrusion nrum hauv txhuas pas nrig, txhuas casting pas nrig yuav tsum tau kho ua ntej extrusion ua kom nws muag, cua sov zoo txhuas casting rods sheng ingot muab tso rau hauv lub thoob extruder sab hauv, thiab tom qab ntawd los ntawm siab lub zog hydraulic lub tog raj kheej thawb extrusion pas nrig, pem hauv ntej kawg ntawm extrusion pas nrig muaj lub ncoo siab, xws li rhaub mos aluminium alloy hauv dummy thaiv hauv qab muaj zog los ntawm pwm precision molding extrusion molding.

Nov yog cov pwm siv rau: daim duab ntawm cov khoom xav tau rau ntau lawm.

Daim duab yog: kab rov tav li qub hydraulic extruder schematic daim duab

Cov kev taw qhia ntawm kev nyab xeeb yog sab laug mus rau sab xis

Qhov no yog cov lus piav qhia yooj yim ntawm cov feem ntau dav siv ncaj qha extrusion niaj hnub no. Indirect extrusion yog cov txheej txheem zoo sib xws, tab sis muaj qee qhov sib txawv tseem ceeb heev.

Nyob rau hauv txheej txheem indirect extrusion.Qhov tuag yog ntsia rau ntawm hollow extrusion bar, kom tus tuag tuag nias ntawm immovable aluminium bar dawb paug, yuam lub aluminium alloy rau extrude ntawm hollow extrusion bar los ntawm kev tuag.

Qhov tseeb, txheej txheem txheej txheem ntxiv yog zoo ib yam li nyem cov tshuaj txhuam hniav. Thaum lub siab nyem siv rau qhov kawg ntawm cov tshuaj txhuam hniav, cov tshuaj txhuam hniav txhuam yog nyem los ntawm kev qhib ncig.

Yog tias qhov qhib tiaj, qhov nyem tshuaj txhuam hniav zoo tuaj tawm ua ib pob.

Yog lawm, cov qauv ua haujlwm kuj tseem tuaj yeem tawm ntawm cov lus qhib ntawm tib lub duab.Piv txwv li cov neeg ua cov ncuav mog qab zib siv cov raj tshwj xeeb zoo nkauj los txhuam cov dej khov ua kom muaj txhua hom kev txhuam.

Thaum koj tsis tuaj yeem ua ntau yam khoom siv nrog tshuaj txhuam hniav los yog dej khov, koj tsis tuaj yeem nyem aluminium mus rau hauv cov hlab nrog koj cov ntiv tes.

Tab sis koj tuaj yeem siv lub tshuab muaj zog xovxwm los txhawm rau txhuas qhov zoo los ntawm cov pwm ua kom muaj pwm los ua cov khoom lag luam ntawm cov khoom lag luam yuav luag txhua yam.

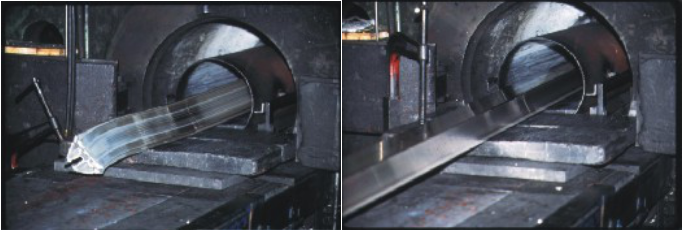

Daim duab hauv qab no (sab laug) qhia thawj ntu ntawm extruder thaum pib ntawm kev extrusion. (txoj cai)

Qhov bar

Aluminium bar yog qhov khoob ntawm txheej txheem txheej txheem extrusion. Aluminium bar siv rau extrusion tuaj yeem ua qhov khoob lossis qhov khoob, feem ntau yog cylindrical, thiab nws ntev yog txiav txim siab los ntawm lub raj extrusion.

Aluminium pas nrig feem ntau yog tsim los ntawm casting, lossis los ntawm forging lossis hmoov forging.Nws feem ntau yog tsim los ntawm sawing aluminium alloy cov kav nrog zoo alloy sib xyaw.

Allolo alloys feem ntau yog tsim los ntawm ntau dua ib qhov khoom siv hlau. Extruded aluminium alloys yog tsim los ntawm cov kab (feem ntau tsis ntau tshaj 5%) cov ntsiab lus (xws li tooj liab, magnesium, silicon, manganese, lossis zinc) uas txhim kho cov khoom ntawm cov ntshiab txhuas thiab cuam tshuam cov txheej txheem extrusion.

Qhov ntev ntawm cov pas nrig txhuas sib txawv ntawm cov chaw tsim khoom mus rau cov chaw tsim khoom, uas yog txiav txim siab los ntawm qhov xav tau qhov ntev kawg, extrusion piv, tawm qhov ntev thiab qhov nyiaj pub ntxiv.

Cov qauv qhov ntev feem ntau yog li ntawm 26 ntiv tes (660mm) txog 72 ntiv tes (1830mm). Cov diameters sab nraud yog li 3 ntiv (76mm) txog 33 ntiv (838mm), 6 ntiv (155 mm) mus rau 9 ntiv (228 mm).

Txoj kev extrusion ncaj qha kev

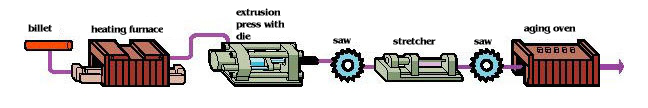

[ntawv xov xwm] [hluav taws xob cua sov] [extrusion nias nrog tuag] pom [daim tawv muag] [kev tiv thaiv kev laus]

Daim duab piav qhia lub hauv paus theem pib ntawm extruding ib qho txhuas bar

Thaum txiav txim siab qhov khoom kawg tau txiav txim siab, tsim nyog aluminium alloy raug xaiv, extrusion tuag raug ua tiav, thiab kev npaj rau qhov tseeb txheej txheem extrusion tiav.

Tom qab ntawd preheat aluminium bar thiab cov cuab yeej extrusion. Thaum lub sijhawm txheej txheem txheej txheem ntxiv, txhuas lub tog raj kheej tau ruaj ruaj, tab sis tau muag muag rau hauv tshuab ua kom sov.

Lub ntsiab lus melting ntawm aluminium alloy yog li 660 ℃ .Qhov kub cua kub ntawm cov txheej txheem extrusion feem ntau ntau dua 375 ℃ thiab tuaj yeem siab txog li 500 ℃, nyob ntawm seb cov mob extrusion ntawm cov hlau.

Cov txheej txheem txheej txheem txheej txheem tiag tiag pib thaum pib qws rho tawm pib thov siab rau lub pas nrig txhuas hauv cov ingot.

Txawv hydraulic xovxwm yog tsim los nyem qhov twg los ntawm 100 tons rau 15,000 tons.Qhov extrusion siab txiav txim siab qhov loj ntawm extrusion tsim los ntawm tshuab extrusion.

Extruded cov ntsiab lus tshwj xeeb yog qhia los ntawm qhov siab tshaj plaws ntu ntu qhov loj ntawm cov khoom, qee zaum kuj los ntawm qhov ncig ntawm qhov khoom.

Thaum lub extrusion nyuam qhuav pib, aluminium bar raug rau qhov kev tawm tsam ntawm lub pwm thiab ua kom luv thiab tuab dua, kom txog rau thaum nthuav tawm ntawm aluminium bar tau txwv los ntawm ingot lub teeb ntsa phab ntsa;

Tom qab ntawd, raws li lub siab txuas ntxiv, cov mos (tseem tawv) hlau tsis muaj qhov chaw ntws thiab pib muab zaws tawm ntawm cov pwm tsim ua qhov txuas mus rau lwm qhov kawg ntawm cov pwm, tsim cov ntawv profile.

Li ntawm 10% ntawm aluminium pas nrig (suav nrog aluminium pas nrig ntawm daim tawv nqaij) tshuav nyob hauv lub taub hau ingot, cov khoom rho tawm yog txiav los ntawm cov pwm, thiab cov hlau ntxiv hauv cov ingot chim yog ntxuav thiab rov qab siv dua.Tom qab cov khoom tawm ntawm pwm, cov txheej txheem tom ntej yog tias cov khoom kub kub ntxiv yog quenched, machined thiab muaj hnub nyoog.

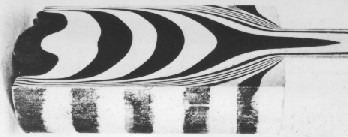

Thaum lub txhuas qhov kub ntom tawm los ntawm cov pwm los ntawm lub taub hau ingot lub tog raj kheej, cov hlau nyob hauv qhov chaw nruab nrab ntawm lub aluminium bar ntws nrawm dua li ntug.Qhov dub txaij nyob hauv daim duab qhia, cov hlau nyob ib ncig ntawm cov plaub yog sab laug kom rov ua dua tshiab raws li tshuav qee leej.

Tus nqi ntawm qhov hluav taws xob tawm yog nyob ntawm cov alloy raug zawm thiab cov duab ntawm lub qhov hluav taws xob tuag lub qhov. Siv cov qhov tawv tawv kom nyem yooj yim rau cov khoom uas muaj cov duab puab tuaj yeem ua kom qeeb li 1-2 ko taw hauv ib feeb.With nrog cov ntsej muag muag, ua cov duab yooj yim tuaj yeem nyem mus rau 180 ko taw ib feeb lossis ntau dua.

Qhov ntev ntawm cov khoom lag luam extrusion nyob ntawm lub txhuas txhuas thiab cov qhov hluav taws xob pwm. Ib qho kev nruam zuj zus tuaj yeem tsim cov khoom lag luam mus txog 200 ko taw ntev. Qhov tseeb molding extrusion, thaum cov khoom extruded tawm cov extruder tso rau ntawm cov swb (sib npaug rau cov khoom siv conveyor);

Raws li cov khoom sib txawv, kev rho tawm ntawm cov khoom lag luam txias hom: muab faib rau cov cua txias, huab cua lossis dej txias tab sis quenching.Qhov no yog cov kauj ruam tseem ceeb los xyuas kom cov metallographic kev ua tau zoo ntawm cov khoom tom qab kev laus.Qhov extruded cov khoom yog tom qab ntawd pauv mus rau lub txaj txias.

Ncaj

Tom qab quenching (txias), cov khoom sib txuas yog ncaj thiab ncaj los ntawm kev ncab lossis ncaj (ncab kuj tseem cais raws li txias ua haujlwm tom qab extrusion) .Thaum kawg, cov khoom lag luam xa mus rau lub tshuab sawing los ntawm cov khoom siv sib tw.

Sawing

Cov khoom lag luam tiav cov sawing yog cov sawing ntawm cov khoom lag luam mus rau qhov kev lag luam tshwj xeeb ntev.Circular saws yog qhov siv ntau niaj hnub no, zoo li teb caj npab saws uas txiav ntev ntev ntawm cov khoom siv extruded feem.

Kuj tseem muaj saws txiav los ntawm sab saum toj ntawm qhov profile (xws li hluav taws xob miter kaw) .Cov khoom siv pom rooj, pom lub rooj yog nrog lub pliav pom cov hniav los hauv qab mus txiav cov khoom, thiab tom qab ntawd cov saw hniav rov qab rau hauv qab ntawm lub rooj rau kev voj voog tom ntej.

Ib qho kev ua tiav ncig pom yog 16-20 ntiv hauv taub thiab muaj ntau dua 100 carbide hniav.Lub qhov pom cov hniav yog siv rau cov taub loj loj extruders.

Kev siv lub tshuab ua kom tiav nws tus kheej yog nruab nrog lub kaw lus uas xa cov roj nplua nyeem rau cov sawtooth kom pom qhov zoo ntawm cov saw thiab cov nplaim hluav taws.

Tsis siv neeg xovxwm nias khaws cov ntu hauv qhov chaw rau sawing thiab cov khib nyiab sawing sau rau kev rov ua dua tshiab.

Laus:

Qee cov khoom extruded xav tau kev laus ua kom tiav qhov zoo tshaj plaws, yog li nws tseem hu ua kev laus. Kev laus ua tiav ntawm chav sov.Qhov kev laus ua tiav hauv qhov cub laus laus.Qhov uas hais tias, nws yog hu ua nag lossis daus kev kho kub kom sov.

Thaum lub profile yog extruded los ntawm lub tshuab extruder, qhov profile yuav dhau los ua ib nrab. Tab sis nws tsis ntev dhau los ua khoom thaum nws txias lossis quenched (txawm hais tias huab cua txias lossis dej txias).

Cov txheej txheem tsis muaj cua sov ua rau alloys (xws li alloys alloys nrog ntxiv magnesium lossis manganese) yog ntxiv dag zog los ntawm ntuj laus dua thiab txias ua haujlwm.Heat kho tau aluminium alloy (xws li aluminium alloy nrog tooj liab, zinc, magnesium + silicon) tuaj yeem tau txais lub zog zoo dua qub thiab lub zog tawv. los ntawm cuam tshuam rau cov kev kho kub ntawm cov qauv hlau metallographic.

Tsis tas li ntawd, kev laus ua kom lub zog ntawm qhov muaj zog ntau theem tusyees sib cais kom tau txais qhov siab tshaj tawm cov khoom ua kom lub zog, ua kom tawv thiab elasticity ntawm tshwj xeeb alloy.

Npuaj

Txawm hais tias qhov cub hluav taws kub lossis chav sov kub, tom qab kev laus tag nrho, cov ntaub ntawv pauv mus rau qhov chaw kho lossis qhov ua kom tob lossis ua kom zoo nkauj los npaj rau kev thauj mus los rau cov neeg siv khoom.

Tib neeg kuj nug

Lub sij hawm tshaj tawm: Mar-20-2020