Tsarin extrusion na Aluminum

Tsarin extrusion na gami na aluminum yana farawa da ainihin samfurin, saboda samfurin samfurin ya dogara ne da bukatun amfani da aka bayar, wanda ke tantance yawancin sigogin karshe na samfurin. Kamar aikin aikin injiniyan kayan, aikin jiyya na sama da amfani da bukatun muhalli. , waɗannan kaddarorin da buƙatu a zahiri suna ƙayyade zaɓin abin da aka kera na haɓakar aluminum.

Koyaya, abubuwan da aka fitar dasu na aluminium an ƙaddara su ta ƙirar ƙirar samfurin. Siffar samfurin yana ƙayyade siffar extrusion mutu.

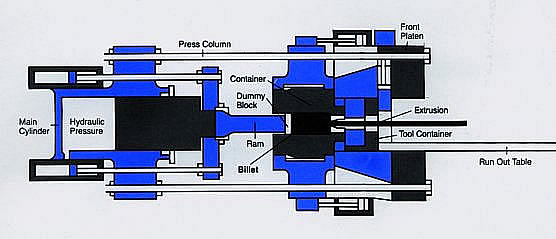

Da zarar an warware matsalar zane, aikin fitar da extrusion mai amfani yana farawa jefa extrusion a sandar aluminium, sandar simintin gyare-gyaren aluminium dole ne a zafafa kafin extrusion ya yi laushi da shi, an sanya dumama kyakkyawan zubin sandar sandar sheng ingot a cikin ganga mai fitarwa a ciki, sannan kuma ta sama hydarfin silinda na wutar lantarki yana tura sandar extrusion, ƙarshen ƙarshen sandar extrusion yana da matsi mai matsi, irin wannan mai laushi mai laushi na aluminium a cikin ɓoyayyen ɓoyayyiya a ƙarƙashin matsin lamba mai ƙarfi daga gyare-gyaren daidaitaccen gyare-gyaren extrusion

Wannan shine abin da abin mora yake: siffar samfurin da ake buƙata don samarwa.

Hoton shine: zane-zane na kwatankwacin kwandon ruwa na sihiri

Hanyar extrusion an hagu zuwa dama

Wannan bayani ne mai sauki game da yaduwar kai tsaye kai tsaye a yau. Fitowar kai tsaye ba irin wannan tsari bane, amma akwai wasu bambance-bambance masu mahimmanci.

A cikin hanyar fitarwa ta kai tsaye. An sanya mutu a kan sandar extrusion mara shinge, don haka ana matse mataccen zuwa bargon almani mara motsi, yana tilasta gami na alminiyon ya wuce zuwa sandar rami ta cikin ramin.

A zahiri, tsarin extrusion yayi kama da matse man goge haƙori. Lokacin da ake amfani da matsin lamba zuwa rufaffiyar ƙarshen man goge baki, ana ruɓe man goge bakin na silinda ta buɗe madauwari.

Idan budewar lebur ce, man goge baki da aka matse yana fitowa a matsayin kintinkiri.

Tabbas, za a iya fitar da siffofi masu rikitarwa a yayin buɗe sura iri ɗaya.Misali, masu kek suna amfani da tubes na musamman don matsi ice cream don yin kowane irin frill.

Duk da yake ba za ku iya yin samfuran amfani da yawa tare da man goge baki ko ice cream ba, ba za ku iya matse alminiyon a cikin bututu da yatsunku ba.

Amma zaku iya amfani da matattarar ruwa mai ƙarfi don fitar da aluminum daga sifa da aka bayar don samar da samfuran fa'idodi iri daban-daban na kusan kowane nau'i.

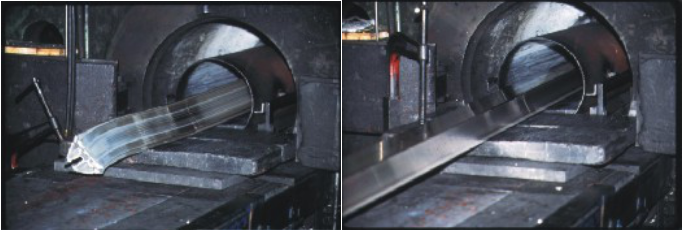

Adadin da ke ƙasa (hagu) yana nuna ɓangaren farko na mai haɓakawa a farkon extrusion. (dama)

Bar

Barikin aluminum shine komai na aikin extrusion. Barikin aluminum da aka yi amfani da shi don extrusion na iya zama mai ƙarfi ko rami, yawanci silinda, kuma ana ƙayyade tsawon sa ta bututun extrusion.

Allon sandunan Almium yawanci ana yin su ne ta hanyar yin simintin gyare-gyare, ko ta hanyar ƙirƙirawa ko ƙera foda.

Aluminium ɗin Aluminium galibi an haɗasu da ƙarfe fiye da ɗaya. Alloarancin gishirin da aka fitar da shi an yi shi ne da alama (yawanci ba ya wuce kashi 5%) (kamar jan ƙarfe, magnesium, silicon, manganese, ko tutiya) waɗanda ke inganta kaddarorin tsarkakakken aluminium kuma suna shafar aikin fitarwa.

Tsawon sandar Aluminium ya banbanta daga masana'anta zuwa masana'anta, wanda aka ƙaddara ta ƙarshen tsayin da ake buƙata, ƙimar extrusion, fitowar tsayi da izinin extrusion.

Matsakaicin tsayi gabaɗaya yana daga inci 26 (660mm) zuwa inci 72 (1830mm). Diamananan diamita daga Ranci 3 (76mm) zuwa inci 33 (838mm), inci 6 (155 mm) zuwa 9 inci (228 mm).

Direct extrusion tsari

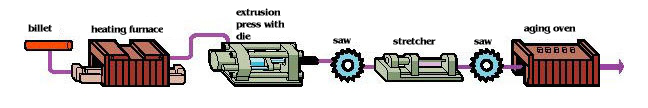

[billet] [dumama kayan wuta] [watsa labaru tare da mutu] ya ga [strecher] [tsufa a dare]

Hoton yana nuna matakan asali na fitar da sandar aluminium

Lokacin da aka ƙaddara fasalin samfurin ƙarshe, ya zaɓi gami da ya dace na aluminium, ƙarancin ƙarancin ƙirar ya ƙare, kuma an kammala shiri don ainihin aikin fitar da kayan.

Sa'an nan kuma preheat sandar aluminum da kayan aikin extrusion. Yayin aikin extrusion, sandar aluminum tana da ƙarfi, amma ya yi laushi a cikin wutar makera.

Matsayin narkewar gami na aluminium ya kai kusan 660 The .Hanyoyin zafin jiki na yau da kullun na yanayin extrusion ya fi 375 ℃ kuma zai iya zama kamar 500 ℃, dangane da yanayin ƙarancin ƙarfe.

Ainihin aikin extrusion yana farawa lokacin da sandar extrusion fara fara matsa lamba ga sandar aluminium a cikin ingot.

An tsara matattarar ruwa daban-daban don matse ko'ina daga tan 100 zuwa tan 15,000. Wannan matsin lamba na ƙaddara girman ƙarancin extrusion da injin ɗin kerawa.

Ana nuna ƙayyadaddun ƙayyadaddun samfura ta matsakaicin girman ɓangaren samfurin, wani lokacin kuma ta hanyar diamita mai zagaye na samfurin.

Lokacin da extrusion ya fara, an sanya sandar aluminium a cikin ƙarfin ƙarfin mai sarrafawa kuma ya zama ya fi guntu da kauri, har sai an taƙaita faɗaɗa sandar aluminum ta bangon gangaren ingot;

Bayan haka, yayin da matsin ya ci gaba da ƙaruwa, ƙarfe mai taushi (mai ƙarfi) ba shi da wurin da zai gudana kuma ana fara matse shi daga ramin da ke sifar ɗin zuwa ɗayan ƙarshen mould ɗin, yana ƙirƙirar bayanan martaba.

Kusan 10% na sandar aluminium (gami da sandar sandar sandar aluminium) an bar shi a cikin gangar ingot, an yanke samfurin extrusion ɗin daga abin da aka yi da shi, kuma sauran ƙarfe da ke cikin gangarsa ana tsabtace da sake sarrafa shi. tsarin da ya biyo baya shine cewa samfurin extrusion mai zafi yana ƙonewa, injiniya da tsufa.

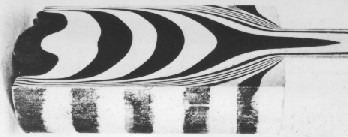

Lokacin da aka fitar da aluminium mai zafin daga abin da ya shafi ta cikin silinda wanda ba shi da ƙarfi, ƙarfe a tsakiyar sandar aluminium yana gudana da sauri fiye da gefen. Kamar yadda baƙin zanen da ke hoton ya nuna, ana barin ƙarfen da ke gefen gefunan a sake yin amfani da shi saura.

Adadin extrusion ya dogara da gami da ake matsewa da siffar ramin fitarwa. Yin amfani da gami mai ƙarfi don matse kayan abubuwa masu rikitarwa na iya zama da sauri kamar ƙafa 1-2 a minti ɗaya. Tare da gami mai laushi, ana iya matse siffofi masu sauƙi zuwa ƙafa 180 a minti ɗaya ko fiye.

Tsawon samfurin extrusion ya dogara da sandar aluminium da kuma ramin fitarwa. Cigaba da fitar da kayan masarufi na iya samar da samfur har tsawon kafa 200. Sabbin kayan gyaran zamani, lokacin da samfurin da aka fitar ya bar abin da aka fitar dashi an sanya shi akan silar (daidai da bel din mai daukar kaya);

Dangane da nau'ikan da ke ciki, fitar da kayan daga yanayin sanyaya samfurin: ya kasu zuwa sanyaya na halitta, iska ko sanyaya ruwa amma quenching.Wannan babban mahimmin mataki ne don tabbatar da aikin karafa na samfurin bayan tsufa. gado mai sanyi.

Mikewa

Bayan sanyaya (sanyaya), an fitar da samfurin da aka shimfida ta madaidaiciya ko madaidaiciya (shimfidawa kuma an lasafta shi azaman aikin sanyi bayan extrusion) .A ƙarshe, ana tura samfurin zuwa mashin ɗin ta hanyar na'urar isar da saƙo.

Sawa

Hankula gama samfurin sawing shine sawing wani samfuri zuwa wani takamaiman tsayi na kasuwanci.Hakanan zagaye sune mafi yawan amfani dasu a yau, kamar masu juya hannun hannu wadanda suke yanke dogayen abubuwan da aka fitar dasu a tsaye.

Hakanan akwai yankan da aka yanke daga saman bayanin martaba (kamar su lantarki miter saw) .Haka kuma tebur mai amfani mai amfani, tebur mai gani yana tare da ruwan faifan diski daga ƙasa zuwa sama don yanke kayan, sannan kuma zafin sawun ya koma ƙasan na tebur don sake zagayowar na gaba.

Hannun da aka gama zagaye na yau da kullun yakai inci 16-20 kuma yana da hakora sama da 100. Ana amfani da manyan ruwan wukake don manyan masu fitar da diamita.

Mashin din da yake shafa mai kai yana sanye da tsarin da zai sadar da mai a cikin dutsen domin tabbatar da ingancin aikin dutsen da kuma saman dutsen.

Latsawa ta atomatik tana riƙe sassan a wurin don sintar kuma ana tattara tarkacen shinge don sake amfani.

Tsufa:

Wasu kayayyakin da ake fitarwa suna buƙatar tsufa don cimma ƙarfi mai ƙarfi, saboda haka ana kiran shi tsufa.Ba a yin tsufa na ɗabi'a a zazzabi na ɗaki.Ana aiwatar da tsufa na wucin gadi a cikin murhun tsufa.

Lokacin da aka fitar da bayanan martaba daga maƙerin, bayanin martabar zai zama mai ƙarfi kamar dalla-dalla Amma da sannu zai zama mai ƙarfi lokacin da aka sanyaya shi ko kuma ya shaƙu (ko a sanyaye ko a sanyaye a ruwa).

Abubuwan da ba su da zafi da ake amfani da su na aluminium (kamar su gishirin aluminum tare da ƙarin magnesium ko manganese) ana ƙarfafa su ta tsufa da yanayin aiki mai sanyi. Allo allo aluminum aluminum aluminum aluminum aluminum aluminum aluminum aluminum aluminum aluminum aluminum aluminum aluminum aluminum aluminum aluminum aluminum aluminum aluminum aluminum aluminum aluminum aluminum aluminum aluminum aluminum aluminum aluminum aluminum aluminum aluminum ta hanyar shafi maganin zafin jiki na tsarin ƙarfe na ƙarfe.

Bugu da kari, tsufa shine ya sanya kwayayen abubuwan da aka karfafa a hade a rabe suke don samun matsakaicin karfin amfanin gona, taurin da laushi na gami na musamman.

Bales

Ko murhun tsufa ko tsufa na ɗaki, bayan cikakken tsufa, ana canja bayanan martaba zuwa jiyya na ƙasa ko bitar aiki mai zurfi ko ƙararrawa masu shiri don hawa zuwa abokin ciniki.

Mutane kuma suna tambaya

Post lokaci: Mar-20-2020