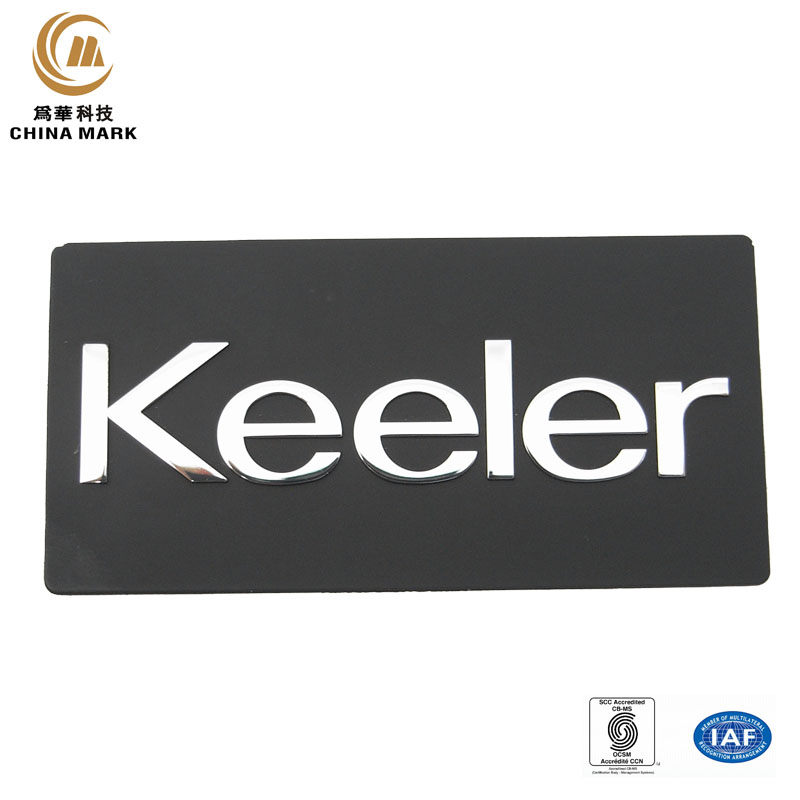

Aluminum nameplate is selected as China standard brand, advanced production equipment, aluminum nameplate high temperature resistance, the product will not change color for a long time!Professional to create high-quality aluminum nameplate daily production up to 50000+ online timely to give you the quotation ~

Aluminum signage refers to the use of aluminum raw materials to produce molding signage, nameplate products, collectively known as aluminum signage.Has the guidance, the instruction, the warning, the warning, the information transmission and the brand publicity and so on function.

Aluminum nameplate manufacturing process

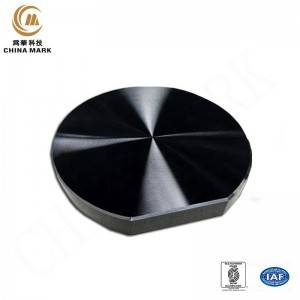

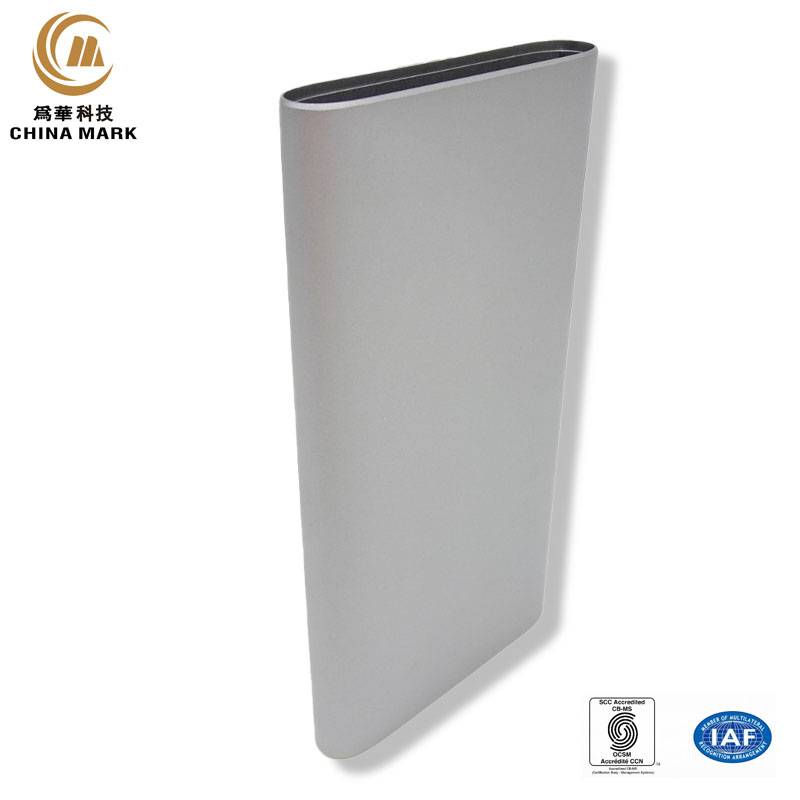

Aluminum plate (Aluminum plate) is one of the many signs of Aluminum plate, usually using Aluminum plate stamping, cutting, concave and convex and Aluminum alloy die-casting processing.

Common processes: high gloss (polishing), decay engraving, oxidation, wire-drawing, laser engraving, electroplating, spraying, spot paint, enamel, baking paint, reflective, luminous printing and other processes.

Surface color: screen printing, four-color offsctdruckereien, thermal transfer printing to complete the color effect, can print a variety of text, number, design and other content.

Use of aluminum nameplate

Aluminum panels in recent years has been widely used in electronics, electrical appliances, machinery and equipment, air conditioning, television, liquid crystal display, navigation, automobile, automobile and motorcycle parts, electric moped, door, security doors, furniture, kitchen utensils and appliances, office supplies, sanitary ware, acoustics, bags, accessories, all kinds of wine box, tea box, moon cake packaging, gift box, and other products LOGO sign.

You may also like:nameplate for TV;Please click to view ~

Do you want to customize a metal sign with colorful, generous and beautiful, scratch-resistant and wear-resistant ? Then anodized aluminum nameplates will be your best choice.

Its color choices are very diverse, and they are generally eye-catching bright colors; it has strong hardness, scratch resistance, and fingerprint resistance. In addition, its corrosion resistance and weather resistance are also very strong.

Who doesn't love such signs? Who doesn't want it?

What are you waiting for? Hurry up and pick up the phone in your hand, contact our business to place an order as soon as possible or get the sign design you want. Business Tel: 86+19926691505