Metal stamping nameplates and their classification

The so-called metal stamping nameplate is to press and mold on the metal material to apply external forces, so that the metal material plastic deformation or separation to get the shape or size we want to shape.

The application of metal stamping process in nameplate making not only makes the size and shape of the same products more accurate but also effectively avoids the waste of materials.

Metal stamping nameplates can be divided into two categories:

I. forming nameplate: the so-called forming nameplate is to make the metal material plastic forming through stamping;

Two, separate the nameplate: this type of nameplate is the metal material through the way of stamping accurately to get the desired size.

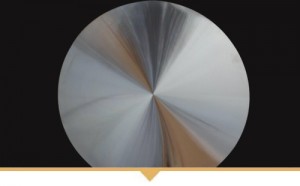

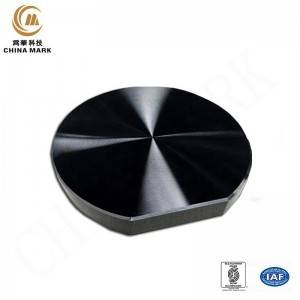

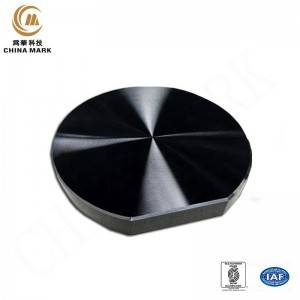

Name: Anodized aluminum cover with CD pattern

Material: 3.0mm thick 5052 Southwest Aluminum

Size: 88x88x13.4mm (3.46”x3.46”x0.52”)

Process: stamping + drawing forming + CNC reverse side+ CNC front side+ polishing + CD pattern + anodizing + high gloss

MOQ: 500, unlimited proofing quantity

Do this need to open the mold? Yes, this style requires mold opening to be molded. Generally, the mold opening and sample cycle is 5-15 days

Use 600T hydraulic press to press and shape, highlight size C1.04+/-0.06mm for control

Nicolas N902 double-sided adhesive tape on the back, film thickness 16~20um

Uses: used as a decoration for audio and power amplifier machines

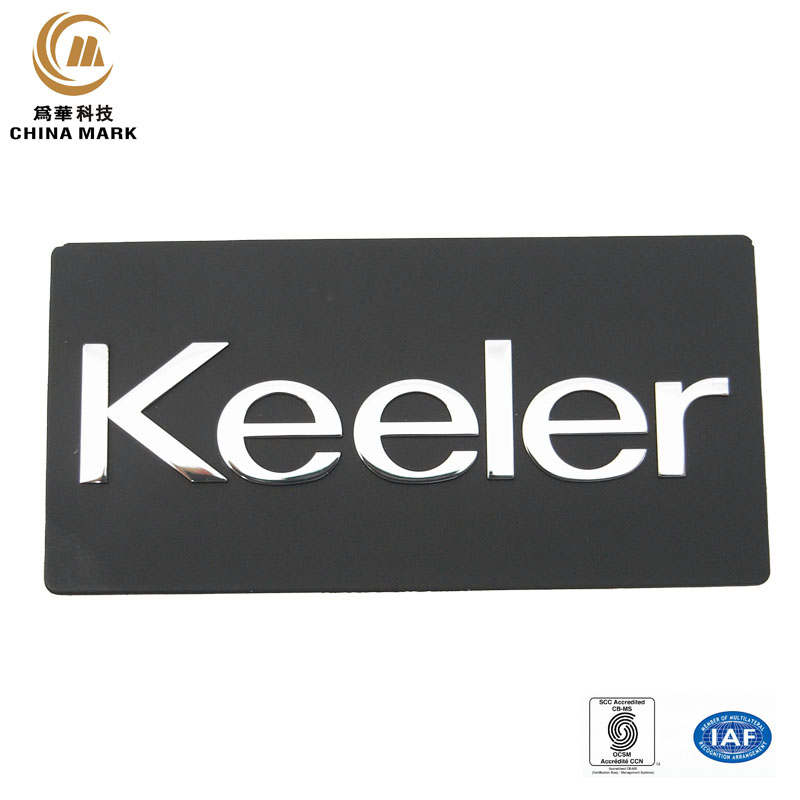

If you want to have your own unique and recognizable custom amp nameplates, then we are the sign supplier you are looking for.

The processing technology and surface treatment methods we involve include stamping, forging, silk printing, brushing, high gloss, batching, anodizing, CD pattern, etching, electroforming, etc.

If you are not sure about our quality, you can directly contact our business whsd08@chinamark.com.cn or call 0086+19926691505 to get free 10-20 samples to be sent for you to check the quality of our products (PS: the shipping fee needs the recipient Pay)

For more, please check: www.cm905.com