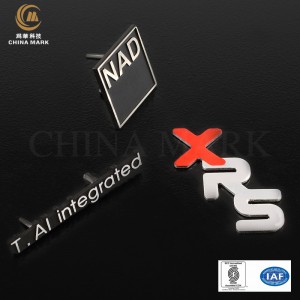

Weihua technology specializes in the production of metal nameplates, first-class technology and service for you to create satisfactory products!Price concessions, delivery on time!Custom brass nameplate, aluminum nameplate for China technology!

Stamping badge process:

The production of stamping badges set badge design, metal stamping and a variety of other badge production process such as gold plating, thickening materials, metal drops, etc.The following is a brief analysis of the production process of stamping badge.

1. Design and manufacture of stamping badges.With the popularization and popularization of computer technology, the design and production of badges mostly adopt computer design draft.The commonly used sketch software in badge industry includes Adobe Photoshop, Adobe Illustrator and Corel Draw, etc. If you want to generate 3D effect drawings, you need the support of 3D Max software.As for the color scheme, PANTONE SOLID COATED is usually used. Because the PANTONE scheme can better match the color and reduce the possibility of color difference, it is used the most.

2. Die for stamping badges.After the design drawing of the badge is made on the computer, the color is removed and the black and white color is made to represent the concave and convex metal black and white picture. The paper is printed in a certain proportion on the sulfate paper, and the engraving template is made with the method of photosensitive ink exposure.Use a carving machine to carve the pattern according to the pattern.When the die is finished, heat treatment is also needed to strengthen the hardness of the die.

3. Suppression.The heat treated stamping badge die is installed on the press table and the design is transferred to the copper or iron sheet.

4. Blanking materials.Using the knife die made in advance, the product according to its shape, with the punch to wash down the product.

5, stamping badge polishing.Put the down product into the polishing machine to polish, remove the burr of stamping, in order to improve the finish of the product.

6. Weld the accessories on the back of the badge.Solder the back of the product with the accessories.

7. Plating the badge.According to the customer's requirements for electroplating, gold plating, silver plating, nickel plating, copper plating and so on.

8. Color the badge.According to customer requirements for coloring, finishing color, high temperature baking, to strengthen the color fastness.

9. Pack badges.Packaging according to the requirements of packaging, ordinary packaging and luxury packaging

You may also like:nameplate for Intellectual speaker;Aluminum name plates,Please click to view ~