To choose a metal sign that is most suitable for you or your company and products, you should consider the following aspects:

1. Economic budget

First of all, we must consider the economic budget of ourselves and the company. If an individual or company sets an economic budget range, then when we choose a metal sign, we should start with this budget. Choose a sign with good quality and good price.

Of course, if you exceed some budget, but the sign technology works well, you can also choose it.

2. Project life cycle

A metal nameplate, it will always have a product life cycle. We have to consider how long this signage will last. If it is only with short-term order, then we can consider not to open the mold, or use a simple mold for label production. Such as: electroformed nickel/copper signs, stainless steel etching signs, etc., these types of signs can be realized without mold opening, of course, the unit price of the product will be higher. Generally, the unit price of this kind of sign can be between $0.3 ~ $78 according to the craftsmanship, the complexity of the pattern and the size of the sign.

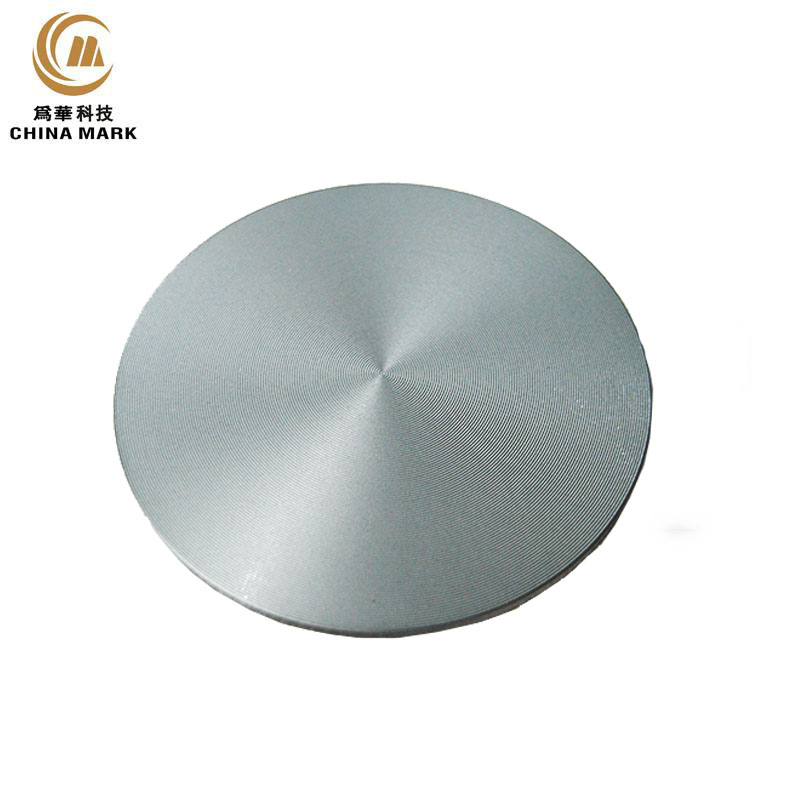

If the life of this sign can last for more than 3 years, and there are more than 10K orders per year, then we strongly recommend that you open a mold for production, so that it can be recycled, and the life of this mold is generally more than 3- 50,000 pcs. There are also some molds that can exceed 100,000 pcs, depending on the mold design structure of each product. Such as: aluminum printed nameplates, aluminum diamond cutting/high-gloss tags, aluminum brushing labels, aluminum CD pattern signs, aluminum anodized signs, stainless steel brushing signs, stainless steel etching stamping signs, etc. The mold price of these signs is generally between $153~$9230, and the unit price of the product is between $0.07~$20.

3. Use of signs and material selection

If you want to make a metal sign that suits your company and meets your company's requirements, the first thing to consider is what purpose the sign is used for, that is, what product it is to be affixed to or fixed on; Or in what environment this sign has been used for a long time.

This not only involves what kind of material to choose, what kind of adhesive is needed, whether it is necessary to bring feet and which ink to use, and so on.

If it is used in machinery and equipment, you can choose stainless steel or aluminum to make; such as used in barometers, air pumps, medical equipment, etc.

If it is used in audio equipment, most of the time is to choose aluminum to make; such as headphones, amplifiers, etc.

If it is used in kitchenware and electrical equipment, you can choose nickel signs, copper signs, stainless steel and aluminum materials to make; such as washing machines, refrigerators, air conditioners, microwave ovens, etc.

At the same time, if the signs are exposed to long-term exposure to the sun, rain, etc., we recommend using stainless steel to make signs, because stainless steel has corrosion resistance, high temperature resistance, and heat resistance properties such as air, steam, water and other weakly corrosive media. Choose stainless steel as the sign material, which is not easy to be corroded and rain washes away important information such as the font and pattern of the sign;

Of course, you can also choose aluminum as the sign material, because aluminum can form a layer of oxide film to prevent metal corrosion in moist air, which can protect the sign to a certain extent.

If the sign has richer color requirements, or the font definition and long service life, then we recommend that you choose anodizing process to make the sign, or spraying and other processes. This kind of process can produce a variety of different colors (white, black). , Silver, orange, green, purple, gold, etc.) signs, and the shelf life of the sign fonts and patterns will be longer

For more machine and sign selection and other uses, please contact our business whsd08@chinamark.com.cn to learn more

4. Process selection of signs

If you just want ordinary signs with fonts or patterns and scratch-resistant, then you can choose printing and brushing processes to make silk-screened and brushed signs

If you have high requirements on the appearance of the sign, such as stain resistance, scratch resistance, corrosion resistance, gloss and not easily damaged, you can choose anodizing with batch or high gloss process to make the sign; or electroforming nickel sign finished, because nickel is highly polished and resistant to corrosion, which makes this sign look very shiny.

Of course, there are other options for the process of signs, such as stamping, forging, hydraulic, high gloss, diamond engraving, brushing, CD pattern, printing, anodizing, laser engraving, etching and so on.

In general, to make a sign, a cheap one can make an exquisite sign with only tens or hundreds of dollars. The slightly more expensive ones are the unit price plus the cost of a mold or fixture, totaling several thousand yuan. The more expensive ones require tens of thousands of molds and the unit price to make, but tens of thousands of molds are rare. Most of the time, high-end, high-quality signs can be produced with only a few dozen to a few thousand.

Learn more about WEIHUA products

We are here to serve you!

Custom metal logo plates - we have experienced and trained craftsmen who can produce reliable, high quality metal identification products using all types of finishes and materials used in today's businesses.We also have knowledgeable and helpful salespeople who are waiting to answer any questions you may have.We are here to help you make the best choice for your metal nameplate!

Post time: Sep-26-2021