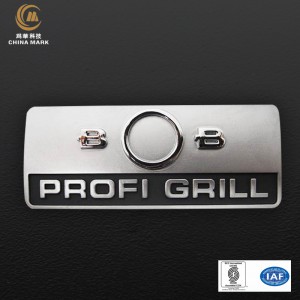

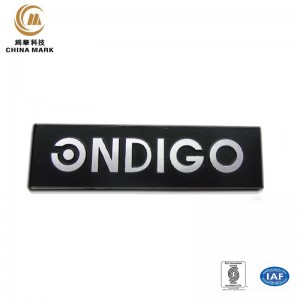

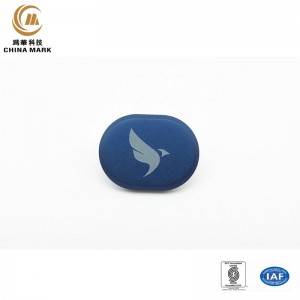

Li-nameplate tsa cast, li-logo tse emisitsoeng, Nameplate bakeng sa seapehi sa ho kenya | CHINA MARK

Haeba u rata ho ikopanya le morekisi oa rona oa thekiso tlanya mona

Ts'ebetso ea mantlha e bonts'a joalo ka tlase

Mohato oa 1: motsoako oa zinki

Hata 2: Sesebelisoa se qhibilihisitsoeng se tsoetseng pele

Mohato oa 3: Lisebelisoa tsa Hi-Precision die-cast

Mohato oa 4: Sesebelisoa se seholo sa li-die-cast

Mohato oa 7: Bahlahlobi ba litsebi le basebetsi ba liphutheloana

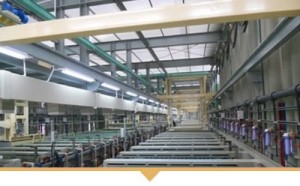

Mohato oa 5: Mohala oa ho tlotsa ka tlung

Mohato oa 8: Likarolo tse hlophisitsoeng

Mohato oa 6: Ovine ea indasteri, tempele ea hi, temp e tlase, temp e sa fetoheng

"Setsi sa rona sa lisekoere-mithara tse 40,000 se na le bokhoni ba ho fihlela li-extrusion aluminium tsohle tsa hau, lipoleiti tsa logo, litlhoko tse nepahetseng tsa ho hatakela hammoho le likhetho tse ngata tsa maiketsetso ho hlahisa tharollo ea lihlahisoa tsa boleng bo holimo. ”

- WEIHUA

E 'ngoe-Litšobotsi tsa motsoako oa zinc ke life?

1.Mosebetsi o motle oa ho lahla, o ka shoa likarolo tse nepahetseng ka likarolo tse rarahaneng le marako a masesaane, a nang le bokaholimo bo boreleli;

2. Kalafo ea bokaholimo: electroplating, spraying, penta, electrophoresis, polishing, phetiso ea metsi, jj .;

3. Ha ho monya tšepe ebile ha ho na ts'enyeho nakong ea ho qhibiliha le ho shoa

4. E na le thepa e ntle ea mochini mme e apara ho hanyetsa mocheso oa kamore;

5. Low qhibiliha ntlha, ho le bonolo ho shoa-lahla.

Tse peli – Mekhoa ea kalafo e sebelisoang khafetsa bakeng sa lihlahisoa tsa li-alloy tsa alloy ke eng?

1. Electrophoresis

2. PVD lephaka

3. Ho khetha motlakase

Tse tharo- Melemo ea ts'ebetso ea kalafo ea bokaholimo ba lihlahisoa tsa li-hardware tsa die-cast ke efe?

1. Electrophoresis: Haholo-holo e sebelisetsoa tšepe e sa hloekang, likarolo tsa li-die-cast tsa aluminium, zinc alloy die-casting likarolo, jj., E ka etsa hore sehlahisoa se bontše mebala e fapaneng, le ho boloka benya ba tšepe, ka nako e ts'oanang bo ntlafatsa ts'ebetso ea bokaholimo, e na le ts'ebetso e ntle ea ho thibela ts'enyeho,

2.PVD vacuum plating: Lebitso le felletseng ke phepelo ea mouoane ea 'mele, e ka sebelisoang ka mebala e fapaneng, joalo ka silevera e benyang, boputsoa ba boloi, ho peperana, ho theola silevera le mebala e meng e supileng;

3. Electroplating: Electroplating ke ts'ebetso e sebelisang motlakase ho kopanya filimi ea tšepe holim'a tšepe ho thibela ho bola, ho ntlafatsa ho hanyetsa ho apara, ho khanna, ho bonahatsa maikutlo le ho ntlafatsa botle. E sebelisoa haholo ebile e koahetsoe Sephatsimisi se phahameng, ponahalo ea tšepe ea boleng bo holimo e ka fumanoa;

4. Ho penta

Lihlahisoa tse hlahisoang ke ente ea mafura li hanela mocheso o phahameng, khohlano, mahlaseli a kotsi, joala, peterole le lihlahisoa tse ling. ho penta ho ka etsa hore lihlahisoa tse monotonous li shebahale li le ntle le ho feta kamora ho fafatsoa ka mebala e fapaneng. Ka nako e ts'oanang, ka lebaka la tšireletso e eketsehileng, e ka lelefatsa bophelo le sehlahisoa sa sehlahisoa.

A mane-Thepa ea zinc alloy die die ke eng?

Thepa ea mochini le thepa ea motlakase ea motlakase oa zinc e ntle haholo. Bophahamo ba bokaholimo, matla le ho atoloha ha li-castings ka semeleng sa ho lahla tsohle li ntle haholo.

Hlano. Ke matla afe a betere, alloyum alloy kapa zinc alloy?

Matla, ho thatafala le ho etsa mosebetsi oa alloy ea zinc li betere ho feta alloyum alloy.