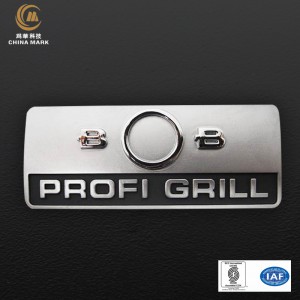

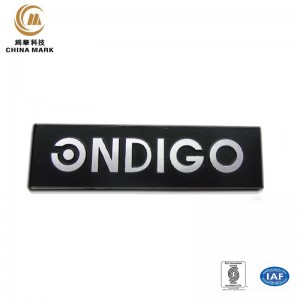

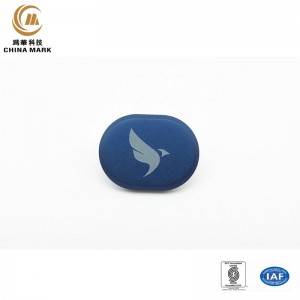

Ama-nameplates we-Cast, ama-logo ahleliwe, i-Nameplate yokupheka kwe-induction | CHINA MARK

Uma unesifiso sokuthintana nomthengisi wethu wokuthengisa chofoza lapha

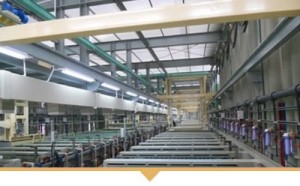

Inqubo esemqoka ibonisa ngezansi

Isinyathelo 1: Zinc alloy

Isinyathelo 2: Idivayisi ehlakazekile esezingeni eliphakeme

Isinyathelo 3: I-Hi-precision die-cast tooling

Isinyathelo 4: Isikali esikhulu sedivayisi yokufa

Isinyathelo 7: Abahloli abangochwepheshe nabasebenza emaphaketheni

Isinyathelo 5: Umugqa we-Galvanizing

Isinyathelo 8: Izingxenye ezihleliwe

Isinyathelo 6: Ihhavini lezimboni, i-hi temp, i-temp low, i-temp engaguquki

“Indawo yethu engamamitha-skwele angama-40,000 inamandla okuhlangabezana nayo yonke i-extrusion aluminium yakho, amalogo amapuleti, izidingo zokushaya iziteki ezihambisana nezinketho eziningi zokuqamba ukukhiqiza izixazululo zemikhiqizo esezingeni eliphakeme. ”

- WEIHUA

Eyodwa – Yiziphi izici ze-zinc alloy?

1.Ukusebenza kahle kokulingisa, kungafa izingxenye ezisetshenzisiwe ezinokuma okuyinkimbinkimbi nezindonga ezincane, ezinendawo ebushelelezi yokusakaza;

Ukwelashwa Surface: electroplating, sishaye, ukupenda, electrophoresis, ezipholisha, ukudluliswa kwamanzi, njll .;

3. Akukho ukumuncwa kwensimbi futhi akukho ukugqwala ngesikhathi sokuncibilika nokufa

4. Inezinto ezinhle zomshini futhi ifaka ukumelana ekamelweni lokushisa;

5.Iphuzu lokuncibilika okuphansi, okulula ukufa.

Zimbili – Yiziphi izinqubo zokwelashwa ezisetshenziswa kakhulu zemikhiqizo ye-zinc alloy die-casting?

1. I-Electrophoresis

2. I-PVD plating plating

3. Ukuqothula ugesi

Okuthathu- Ziyini izinzuzo zenqubo yokwelashwa ebusweni yemikhiqizo ye-zinc alloy die-casting hardware?

1. I-Electrophoresis: Ikakhulu isetshenziselwa insimbi engagqwali, izingxenye ze-aluminium alloy die-casting, izingxenye ze-zinc alloy die-casting, njll., Zingenza umkhiqizo ubonise imibala ehlukahlukene, futhi igcine ukukhanya kwensimbi, ngasikhathi sinye kuthuthukise ukusebenza komhlaba, inokusebenza okungcono kokulwa nokugqwala,

2. I-PVD plating plating: Igama eligcwele ukufakwa komphunga ngokomzimba, ongasetshenziswa ngemibala ehlukahlukene, njenge-flash silver, magic blue, crack, drop silver neminye imibala eyisikhombisa;

3. I-Electroplating: I-Electroplating inqubo esebenzisa i-electrolysis ukunamathisela ifilimu yensimbi ebusweni bensimbi ukuvimbela ukugqwala, ukuthuthukisa ukumelana nokugqoka, ukuqhuba, ukubukeka, nokwenza ngcono ubuhle. Isetshenziswa kabanzi futhi ifakwe isicwebezelisi Esiphezulu, ukubukeka kwensimbi esezingeni eliphakeme kungatholakala;

4. Ukudweba

Imikhiqizo ekhiqizwa umjovo kaphethiloli iyamelana nokushisa okuphezulu, ukungqubuzana, i-ultraviolet, utshwala, uphethiloli neminye imikhiqizo. ukudweba kungenza imikhiqizo eyisidina ibukeke yinhle kakhulu ngemuva kokufafazwa ngemibala ehlukahlukene. Ngasikhathi sinye, ngenxa yesendlalelo esingeziwe sokuvikela, futhi singakwelula impilo nempilo yesevisi yomkhiqizo.

Okune-Yiziphi izakhiwo ze-zinc alloy die casting?

Izici zemishini nezakhiwo ze-electroplating ze-alloy zinc kuhle kakhulu. Ubukhulu bendawo, amandla kanye nokwelula kokuphosa esitshalweni sokulingisa konke kuhle kakhulu.

Okuhlanu. Yimaphi amandla angcono, i-aluminium alloy noma i-zinc alloy?

Amandla, ubulukhuni nokwakha umsebenzi we-zinc alloy angcono kune-aluminium alloy.