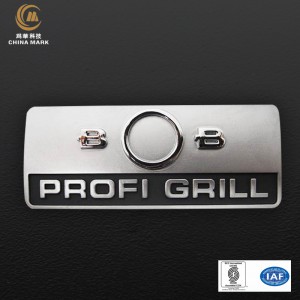

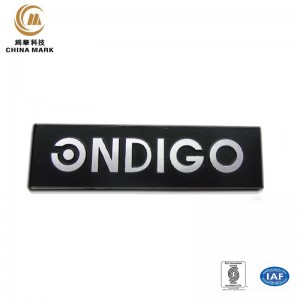

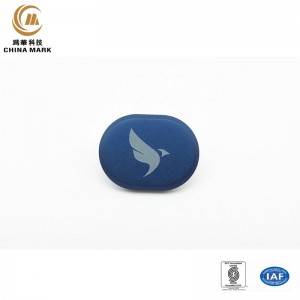

Amagama okuphosa, iilogo ezimiselweyo, i-Nameplate yesipheki sokungenisa | ETSHAYINA

Ukuba unomdla wokunxibelelana nentengiso yethu cofa apha

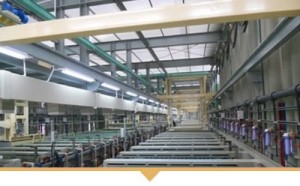

Inkqubo ephambili ibonisa apha ngezantsi

Inyathelo 1: iZinc alloy

Inyathelo 2: Isixhobo esichithwe phambili

Inyathelo 3: Isixhobo esichanekileyo sokufa ngokuchanekileyo

Inyathelo 4: Isixhobo esikhulu sokufa

Inyathelo 7: abahloli abaqeqeshiweyo kunye nabasebenzi bokupakisha

Inyathelo 5: Umgca weGalvanizing

Inyathelo 8: Amacandelo amiselweyo

Inyathelo 6: Ishishini i-oven, i-temp temp, i-temp ephantsi, i-temp rhoqo

"Indawo yethu yeemitha zesikwere ezingama-40,000 inamandla okuhlangabezana nayo yonke i-aluminium yakho ye-extrusion, iipleyiti zelogo, iimfuno zokunyathela ngokuchanekileyo kunye neendlela ezininzi zokuvelisa ukuze kuveliswe izisombululo zemveliso ekumgangatho ophezulu. ”

- WEIHUA

Inye – Yintoni iimpawu ze-zinc alloy?

1.Ukuphosa ukusebenza kakuhle, kungafa iindawo zokuchaneka ngokuma okuntsonkothileyo kunye neendonga ezibhityileyo, ezinendawo egudileyo yokuphosa;

2. unyango Surface: electroplating, ukutshiza, ukupeyinta, electrophoresis, ipolishi, ugqithiso lwamanzi, njl .;

3. Akukho kufakwa kwesinyithi kwaye akukho ukubola ngexesha lokunyibilika kunye nokufa

4. Inezinto ezifanelekileyo zomatshini kwaye inxiba ukumelana nobushushu begumbi;

5. Indawo yokunyibilika ephantsi, kulula ukuyilahla.

Mbini – Zithini iinkqubo zonyango olusetyenziswa ngokuxhaphakileyo kwimveliso ye-zinc alloy die-cast?

1. Electrophoresis

2.IpvVD ingubo

3. Ukukhetha ngombane

Zintathu- Zeziphi izibonelelo zenkqubo yonyango yomphezulu we-zinc alloy die-casting-hardware products?

1.I-Electrophoresis: Isetyenziselwa izinto ezingenasici ezingenanto, i-aluminium alloy die-casting parts, i-zinc alloy die-casting parts, njl., Ingenza imveliso ibonise imibala eyahlukeneyo, kwaye igcine ukukhanya kwensimbi, ngexesha elifanayo ukuphucula ukusebenza komhlaba, ukusebenza ngcono anti-umhlwa,

2.Ipvvva yokutsala iplastikhi: Igama elipheleleyo kukufakwa komphunga ngokwasemzimbeni, onokusetyenziswa kwimibala eyahlukeneyo, enje ngesilivere edanyazayo, ngomlingo oluhlaza okwesibhakabhaka, ngokuqhekeka, ngokulahla isilivere neminye imibala esixhenxe;

3. Ukwenza umbane ngombane: Inkqubo yokwenza i-electrolysis ukuqhoboshela ifilim yesinyithi kumphezulu wesinyithi ukuthintela ukubola, ukuphucula ukuxhathisa ukunxiba, ukuqhuba, ukubonakalisa nokubonisa ubuhle. Kusetyenziswa ngokubanzi kwaye kugqitywe i-Gloss ephezulu, ukubonakala kwensimbi ephezulu kunokufumaneka;

4. Ukupeyinta

Iimveliso eziveliswa ngenaliti yezibaso ziyanyangeka kubushushu obuphezulu, ukukhuhlana, i-ultraviolet, utywala, ipetroli kunye nezinye iimveliso. ukupeyinta kunokwenza iimveliso ezingathandekiyo zibukeke zihle ngakumbi emva kokutshizwa ngemibala eyahlukeneyo. Kwangelo xesha, ngenxa yomaleko owongezelelweyo wokhuseleko, inokwandisa ubomi kunye nobomi bemveliso.

Zine-Zeziphi iipropati ze-zinc alloy die casting?

Iipropathi zoomatshini kunye neepropathi zokwenza i-electroplating ze-alloy zinc zilunge kakhulu. Uburhabaxa bomhlaba, ukomelela kunye nokwanda kokuphoswa kwesityalo sokuphosa konke kulungile.

Ntlanu. Ngawaphi amandla angcono, i-aluminium alloy okanye i-zinc alloy?

Amandla, ubulukhuni kunye nokwenza umsebenzi we-zinc alloy kubhetele kune-aluminium alloy.