The stamping process is a metal processing method, which is based on the plastic deformation of metal. It uses molds and stamping equipment to apply pressure to the sheet to cause plastic deformation or separation of the sheet, so as to obtain a certain shape, size and performance. Parts (stamped parts).

The stamping process can be divided into four basic processes:

Punching:

The stamping process (including punching, blanking, trimming, cutting, etc.) that separates the sheet.

Bending:

The stamping process of bending a sheet into a certain angle and shape along the bending line.

Deep drawing:

A stamping process that transforms a flat sheet into various open hollow parts, or further changes the shape and size of the hollow parts.

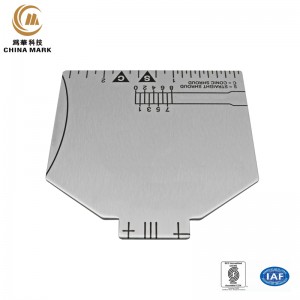

Local forming:

the stamping process (including flanging, bulging, leveling and shaping processes, etc.) that uses various local deformations of different properties to change the shape of the blank or stamping part

Metal sign VS plastic sign

1. Metal signs are harder than plastic signs and are not easily deformed. The plastic signs are prone to bend, deform, and even break.

2. The metal sign has fire resistance. Plastic signs are the most afraid of fire and will melt when exposed to an open flame or

It is ignited, and the metal material will not be deformed due to open flame and short-term high temperature.

3. Metal signs are not easy to deteriorate and fade. Metal signs can be exposed to high temperature indoors or outdoors for a long time and are not easily deteriorated and fading, but plastic signs are prone to deterioration and fading when exposed to rain or high-temperature exposure, or even directly fall off and deform.

4. Metal signs can be recycled and reused. In terms of environmental protection, it is a recyclable material, while plastic is doesn’t belong to this category.

5. Wide application range of metal signs. It can be used in various industrial machinery and equipment, audio equipment, kitchen utensils, electronic and electrical equipment, cosmetics and other industries.

Overall, the best choice is metal signs.

Customize hardware signs, silk-screen signs, brushed signs, anodized signs, CD texture signs, high-gloss engraving signs, etching signs, etc. You can directly contact our sales staff for more information. Email: wh@chinamark.com.cn, Tel: 0086+19926691505

People also ask

What are the functional advantages and USES of aluminum nameplates?