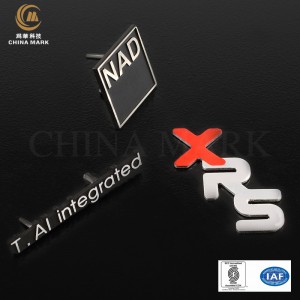

Mekhoa ea Product Product Nameplate

Ho hatakela

Ho hatakela ke mokhoa o sebetsanang le khatello o sebelisang hlobo e kentsoeng mochining oa khatiso ho kenya khatello ho sesebelisoa mochesong oa kamore ho baka karohano kapa polasetiki ea polasetiki ho fumana likarolo tse hlokahalang.

Lisebelisoa tse sebelisoang khafetsa bakeng sa ho hatakela ke: Lisebelisoa tsa tšepe: tšepe e tloaelehileng ea sebopeho sa khabone, tšepe ea boleng bo holimo ea tšepe, tšepe ea sebopeho sa tšepe, sesebelisoa sa khabone, tšepe e sa hloekang, tšepe ea silicon ea motlakase, jj.

Benche e taka tšepe

Mokhoa oa ho taka bokaholimo ba motsoako oa aluminium: ho taka ho ka etsoa ka lijo-thollo tse otlolohileng, lijo-thollo tse sa reroang, khoele, masenke le mabele a ntseng a bilika ho latela litlhoko tsa mokhabiso.

E nchafatsa maikutlo

Mekhoa e latelang ea kalafo ea 'mala oa oxidation e sebelisoa:

1. Filimi ea 'mala oa anodic oxide ea' mala oa Aluminium anodic oxide e entsoe ka dae ea adsorption.

2. 2. Filimi ea "anodic oxide oxide" e itlhahelang feela. Filimi ena ea oxide ea oxide ke mofuta oa filimi ea anodic oxide e mebala e hlahisoang ke alloy ka boeona tlasa tšebetso ea electrolysis ho elektrolyte e itseng e loketseng (hangata e ipapisitse le asiti ea manyolo). Filimi e sa tsejoeng.

3. Mmala oa electrolytic oa filimi ea oxide ea oxide e mebala ka tšepe kapa tšepe ea oxide eleketrode ka likheo tsa filimi ea oxide.

mongolo oa taemane

lipampiri tsa moetlo tsa aluminiumtaemane e itšeha e ka boloka matla a ho qobella hantle esita le maemong a batang haholo, thatafalo e phahameng, matla a phahameng a mochini, khanyetso e ntle ea abrasion, matla a khoheli a lebone, le index ea mocheso e ka bang 80c. E ka boloka botsitso bo botle maemong a batang haholo, thibelo ea mollo, ts'ebetso e bonolo, le khanya e ntle. Ho bonolo ho mebala, 'me theko e tlase ho feta tse ling tsa thermoplastics. Lisebelisoa tse tloaelehileng ke lisebelisoa tsa elektroniki tsa bareki, lintho tsa ho bapala, lihlahisoa tse bolokang tikoloho, li-dashboard tsa koloi, liphanele tsa mamati le li-grilles tsa kantle.

Ho qhoma ha lehlabathe

Ts'ebeliso ea sandblasting holim'a tšepe e atile haholo. Molao-motheo ke ho ama likaroloana tse khorisang tse potlakileng holim'a tšepe ho fihlela mafome a tlosoang, ho qhekella, ho qhekella kapa ho itšireletsa pele holim'a metsi, jj, tse ka fetolang qetello ea tšepe le boemo ba khatello ea maikutlo. Mme mekhahlelo e meng e amang theknoloji ea sandblasting e hloka ho tsotelloa, joalo ka mofuta oa khorofo, boholo ba phatsa ea khorofo, sebaka sa spray, lehlakore la spray le lebelo.

Laser

Ts'ebetso ea kalafo ea bokaholimo ho sebelisoa melaoana ea mahlo, e atisang ho sebelisoa likonopong tsa mehala ea thekeng le ho lidikishinari tsa elektroniki.

Hangata mochini o fatiloeng lejoeng ka laser o ka ngola lintho tse latelang: lihlahisoa tsa lehlaka le lehong, plexiglass, poleiti ea tšepe, khalase, lejoe, kristale, Corian, pampiri, boto ea mebala e 'meli, alumina, letlalo, polasetiki, epoxy resin, polyester resin, Plastic sprayed tšepe.

khatiso ea skrine

Stensele e nang le litšoantšo kapa lipaterone e hoketsoe skrineng bakeng sa khatiso. (E loketse marulelo a bataletseng, a kobehileng a le mong kapa a kobehileng a nang le lerotholi le lenyane) Hangata terata ea terata e entsoe ka nylon, polyester, silika kapa letlooeng la tšepe. Ha substrate e behiloe ka kotloloho tlasa skrineng ka stensele, enke ea ho hatisa skrineng kapa pente e pepetoa ke sesifa ka har'a letlooeng bohareng ba skrine ebe e hatisoa ho substrate