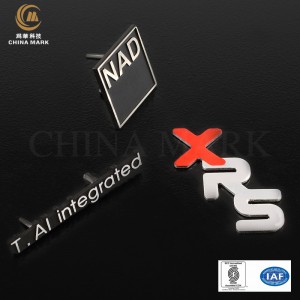

Cov Khoom Siv Ua Haujlwm Hlau Nameplate

Stamping

Stamping yog lub siab ua cov txheej txheem uas siv cov pwm tsim rau ntawm xovxwm kom siv siab rau cov khoom hauv chav sov kom ua rau kev sib cais lossis cov yas deformation kom tau txais cov ntu.

Cov ntaub ntawv nquag siv rau stamping yog: ferrous hlau: cov pa roj carbon zoo tib yam txheej txheem steel, zoo siab carbon steel, alloy yam ntxwv hlau, carbon cuab tam steel, stainless hlau, hluav taws xob silicon steel, thiab lwm yam.

Lub rooj ntev zaum kos hlau

Cov txheej txheem kos txheej txheem ntawm txhuas cov xim hlau: kev kos duab tuaj yeem ua cov nplej ncaj, cov nplej tsis sib xws, xov, corrugated thiab muab kauv nplej raws li qhov xav tau.

Anodizing

Cov kev kho xim oxidation nram qab no tau siv:

1. Cov xim av anodic oxide zaj duab xis Txhuas anodic oxide zaj duab xis yog xim xim los ntawm adsorption ntawm dyes.

2. 2. Spontaneous xim anodic oxide zaj duab xis. Qhov no anodic oxide zaj duab xis yog ib hom ntawm cov xim av anodic oxide zaj duab xis nthawv tsim los ntawm cov alloy nws tus kheej hauv qab qhov kev txiav txim ntawm electrolysis hauv qee qhov tsis haum electrolyte (feem ntau raws li cov organic acid). Anodized zaj duab xis.

3. Lub tshuab hluav taws xob hluav taws xob ntawm cov yeeb yaj kiab anodic oxide yog xim los ntawm hlau lossis hlau oxide electrodeposition los ntawm qhov khoob ntawm oxide zaj duab xis.

pob zeb diamond engraving

kev cai txhuas lub npepob zeb diamond txiav nws tuaj yeem tswj tau zoo compressive zog txawm nyob rau hauv qis kub, hardness siab, siab txhua yam lub zog, zoo abrasion tsis kam, lub teeb lub zog sib txawv, thiab qhov txheeb ze kub txog li 80c. Nws tseem tuaj yeem tswj tau qhov zoo nyob rau qhov kub thaum muaj qhov kub thiab txias, tiv thaiv kev kub nyhiab, cov txheej txheem yooj yim, thiab lub ntsej muag zoo. Nws yog qhov yooj yim rau xim, thiab tus nqi qis dua li lwm cov thermoplastics. Cov kev siv dav dav yog cov neeg siv khoom siv hluav taws xob, khoom ua si, cov khoom lag luam ib puag ncig, cov tsheb sib tw, cov qhov rooj, thiab cov qhov cub sab nraum zoov.

Khawv Koob

Daim ntawv thov ntawm sandblasting rau ntawm hlau saum npoo yog dav heev. Lub hauv paus ntsiab lus yog muaj kev cuam tshuam ceev nrawm abrasive hais rau cov hlau saum npoo kom ua tiav xeb tshem tawm, deburring, deoxidation los yog thawm sab nraud, thiab lwm yam, uas tuaj yeem hloov qhov ua tiav ntawm cov xim hlau thiab kev nyuaj siab lub xeev. Thiab qee qhov kev cuam tshuam uas cuam tshuam rau kev siv tshuab sandblasting yuav tsum tau them sai sai rau, xws li hom abrasive, qhov me me ntawm cov abrasive, cov tshuaj tua kab deb, lub kaum xim tshuaj tsuag thiab qhov nrawm.

Laser

Cov txheej txheem ntawm kev kho saum npoo yog siv cov ntsiab cai kho qhov muag, uas feem ntau siv cov khawm ntawm cov xov tooj txawb thiab cov phau ntawv txhais lus hluav taws xob.

Feem ntau siv lub tshuab laser engraving tuaj yeem sau cov ntaub ntawv hauv qab no: xyoob thiab ntoo khoom, plexiglass, hlau phaj, iav, pob zeb, siv lead ua, Corian, ntawv, ob-xim board, alumina, tawv, yas, epoxy resin, polyester cob, Yas tsuag hlau.

npo luam ntawv

Lub stencil nrog cov duab lossis cov qauv txuas nrog rau lub vijtsam luam tawm. (Haum rau tiaj, ib qho nkhaus lossis nkhaus qhov chaw nrog qhov poob me me) Feem ntau cov xaim xaim xaim yog ua los ntawm nylon, polyester, silk lossis hlau mesh. Thaum lub substrate tau ncaj qha tso rau hauv qab qhov screen nrog stencil, tshuaj ntsuam luam ntawv number case lossis xim yog nyem los ntawm cov squeegee los ntawm cov mesh hauv nruab nrab ntawm lub vijtsam thiab luam tawm ntawm lub substrate