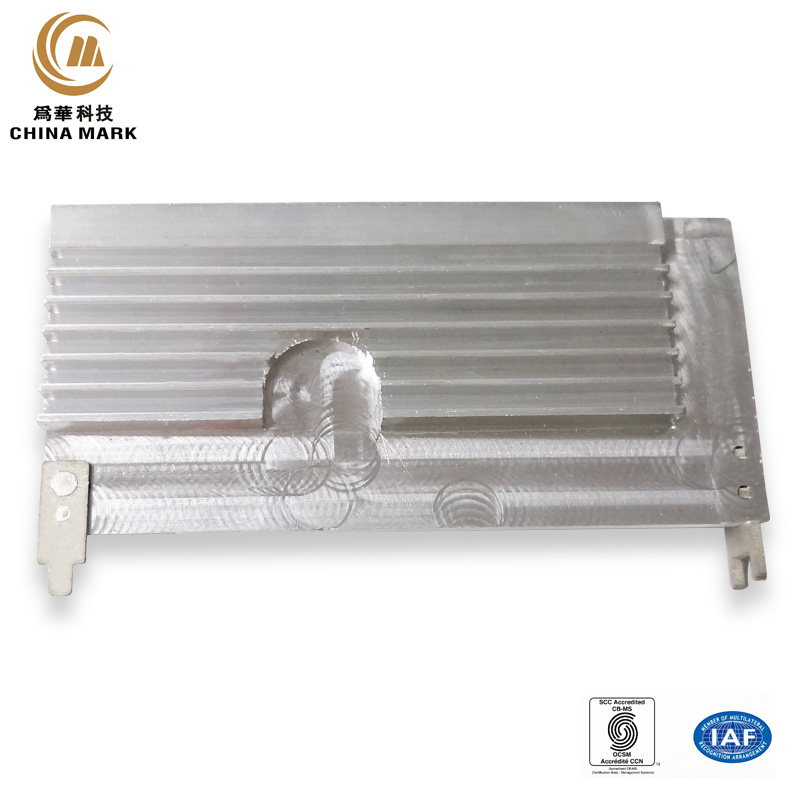

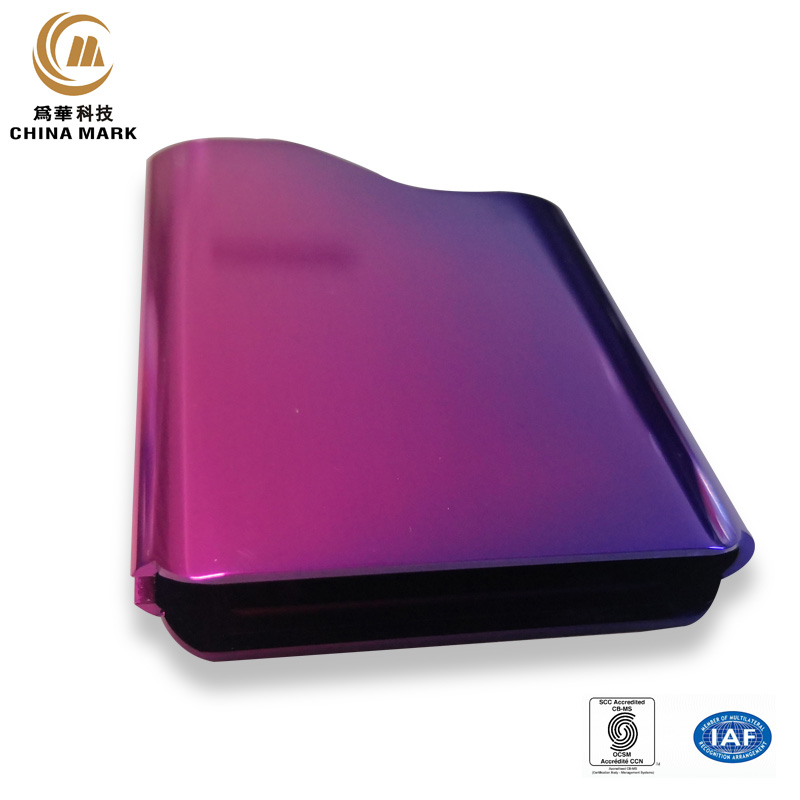

ʻO ka extrusion alumini: ʻO ke kinikini alumini (deformation) ingot extrusion molding process me ka extruder.

ʻOihana ʻenehana extrusion alloy

Hoʻokaʻina o nā ʻaoʻao extruded:

Paukū paʻa: ʻaʻohe puka o ka ʻāpana.

Hollow profile: he mau puka ko ka ʻaoʻao pili.

'Ole a me ka hoʻolālā o ka maʻalahi extrusion make:

ʻO ka Tube extrusion extrusion e make aia ʻelua: ʻo ka mea mua kahi extrusion make make. ʻO ka lua o ka hollow profile extrusion die. ʻO ke ʻano kikoʻī penei:

1) pahu pahu extrusion: kahi kino paukū multi-layer i hana ʻia i ke kila kila kiʻekiʻe, hiki ke hoʻokuʻu ʻia me ka pale o loko. Hoʻoholo ʻia ka lōʻihi e like me ka ton extrager. Mea Pono: coat 5CrMnMo, 3Cr2W8V i hoʻonohonoho ʻia.

2) kākoʻo punahelu: hōʻoia i ka punahelu a me ka popopo pad i concentric, mea e hoʻouka i ka punahelu, punahelu pad kākoʻo mea hana.

3) pad pad: ua like ka nui o ka pad die a me ka die, ʻo kona mānoanoa he 3 mau manawa o ka mānoanoa make, a halihali pū me ka die extrusion me ka make. Die pad, make ka nui o ka puka make ma mua o ka punahelu. : mea kila oka hao.

4) kaomi kaomi: nā mea kōkua kōkua e hōʻoia i ka neʻe ʻole o ka moʻo i ka wā extrusion a pili pono me ka pahu extrusion. Hoʻoholo ʻia ke ʻano a me ka nui e like me ka tonnage o ka extruder.

5) extrusion gasket: mea kōkua kōkua e pale aku i ka hoʻopili pololei ʻana ma waena o ka lāʻau extrusion a me ka metala extruded. ʻOi aku ka liʻiliʻi o ke anawaena o waho i ke anawaena o ka pahu extrusion, a ʻo kona mānoanoa aia ma waena o 40 mm a me 150mm.

6) lāʻau extrusion: ke hana ka lāʻau extrusion, komo ia i loko o ka cylinder extrusion a me nā pilina me ka pad extrusion. Hoʻokomo ʻia ka mea lawe extrusion i ka kaomi extrusion kiʻekiʻe o ka extruder. Mea Pono: 3Cr2W8V.

ʻO ke kumu hoʻonohonoho hole make:

ʻO ka hoʻonohonoho ʻana o ka lua kūmole hole: ʻo ka mea maʻamau ka kikowaena o ka umekaumaha a me ke kikowaena mould i kūlike. Inā ʻokoʻa ka mānoanoa o ka paia, pono e hoʻonohonoho ʻia ka hapa lahilahi i waenakonu o ka puna.

ʻO ka hoʻonohonoho puka make porous profile: no ka ʻāpana liʻiliʻi a i ʻole ʻāpana symmetry maikaʻi ʻole, hoʻohana pinepine ʻia i ka popo porous. ʻAʻole pono ka liʻiliʻi ma waena o nā lua o ka popo popo.

Ka hoʻoholo ʻana i ke kāʻei hana puka make:

1) e lawe i ka ʻāpana āpau e like me ka pae hoʻohālikelike, kahi o ka lōʻihi e hana ai (1.5 a 2) mau manawa o ka mānoanoa o ka huahana i hoʻopau ʻia.

2) ʻo ka lōʻihi o ka pae hana e pili ana i kahi kiko kuhikuhi ka lōʻihi o ka bande hana ma ka helu kuhikuhi me 1mm.

3) me ka mānoanoa like, ʻo ka lōʻihi o ka hana ma ka mamao like mai ke kikowaena o ka hopena he like.

4) e hoʻomaka ana mai ke kikowaena o ka mould, hiki ke hāʻawi ʻia i ka hoʻonui a me ka hōʻemi ʻana o ka lōʻihi hana o kēlā me kēia mamao o 10mm i nā puke pili pono.

5) nā pahi hakahaka i ke kāʻei hana: ʻo nā pahi hakahaka loa e hoʻonāwaliwali i ka ikaika o ke kāʻei hana o ka popopo.

Poloka huina:

Ke ʻoi aku ka lōʻihi o ka hana o ka puka make ma mua o 15 a 25mm, i ka ʻoiaʻiʻo, ʻaʻole kūpono ke metala me ke kaha hana ma muli o ka nui o ka shrinkage, i kēia manawa, hiki ke hoʻoponopono i ke ana kahe o ka mea hao e ka Angle ālai. ʻO ka Angle ma waena o ka busbar a me ka laina kikowaena extrusion o ke kāʻei hana ka ālai ʻana i ka Angle, a ʻo ka mea ʻoi loa ka poloka ʻo Angle he 3 a 5 kekelē.

ʻO ka huina kahe: ʻo ka mea nui, ʻo ka kahe kahe kahi sime symmetrical cone a i ʻole he kone hū ʻia ma ka helehelena hopena o ka punahelu.

ʻO ka mea i luna e pili ana i ka mea extrusion alumini a me ka ʻenehana extrusion alumini e pili ana i ka hoʻolauna ʻana: He ʻoihana mākou ka hana extrusion alumini ʻoihana, hiki ke hāʻawi: arc aluminika extrusion, triangle alumini extrusion a me nā lawelawe lawelawe hana pilikino pilikino ʻia. Welina e kūkākūkā ~

Ka manawa o ka manawa: Apr-11-2020