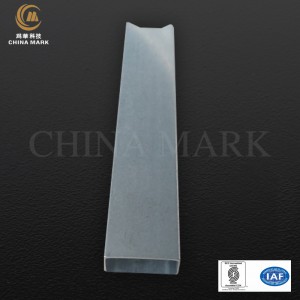

Precision aluminium extrusion

Create precision custom aluminum extruded profiles

The best aluminum extruder needs to truly understand the needs of the end user. Our high-quality, certified aluminum material, automatic aluminum extruder provides an ideal environment for the development of precision customized aluminum extruders to meet your needs.

We will provide you with personalized service, high-quality manufacturing, and satisfaction that will exceed your highest expectations.

Aluminum extrusion functions:

General extruder produces standard and precision customized aluminum extruded profiles.

Our ability to produce complex custom extruded profiles, dimensional tolerances, and surface finishes that are more stringent than industry standards have been key to our continued success over the years.

Our aluminum extruder is controlled by an integrated computer program to provide consistent quality to our customers.

Production capacity:

1 、The plant in weihua includes a 2,000-ton aluminum extrusion workshop and 40,000 square meters of production facilities, including our secondary manufacturing and finishing capabilities.

2、Alloys provided:3003, 6005A, 6061, and 6063.

3、Use visual system technology to accurately check the geometry and dimensions of aluminum extruded profiles.

4、We have the ability to provide internal tensile testing to ensure that we meet your material performance requirements.

Custom aluminum extruded profiles

Ultra-precision aluminum extrusion can reduce the amount of waste by up to 95%, especially for complex product shapes and contours. Inspection costs can also be reduced, with less time to install and shorter lead times for parts. We will work closely with you to create quality products; We will ensure that the tolerance of your products is the most precise, the quality requirements are feasible;

Order now

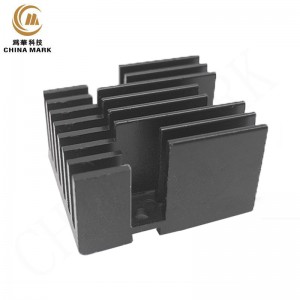

Our highly skilled team of experts takes pride in being able to produce the most complex aluminum extrusion designs from a wide range of industries; Our engineers want to be able to accurately meet the exact specifications of the aluminum components used in their products. It is expected that everything from aluminum extruded profiles to machining, manufacturing and finishing will fully meet your expected functional requirements.

It is an enterprise of weihua aluminum extrusion company that can complete all the processing steps from aluminum ingot extrusion to cutting, finishing, surface treatment, etc., within the company; We specialize in die opening and punching/pulling/forging /CNC production and processing of aluminum products, specializing in the production of aluminum shell manufacturers, aluminum profile shell, mobile power supply aluminum shell, aluminum profile shell processing, 3C, and consumer electronics, etc., with hundreds of samples;

The extruded aluminum electronics enclosures has the advantages of a lightweight, high strength, good heat dissipation performance, beautiful surface, corrosion resistance, no cutting in the bore.