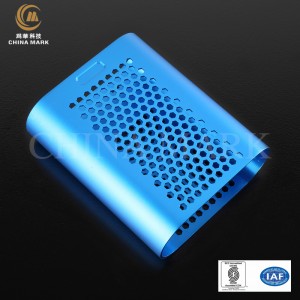

Weihua (CNC precision machining llc) -- specialized in providing precision turning parts, CNC precision manufacturing and processing services;We use the environmental protection material to resist the corrosion, each process QC full detection, the surface is smooth without burr, shipment than the peer 2-5 days faster, welcome you to consult;

What factors will affect the precision of CNC parts?

In the precision nc machining industry, in order to improve the machining efficiency and reduce the error of the workpiece, the workpiece to be processed needs to be fixed by the fixture.So it is widely used, it can not only reduce the labor intensity of workshop workers, but also can expand the scope of use of machine tools, so as to ensure the quality of precision CNC parts processing, improve production efficiency.

Jig design rationality, as well as its use status, in a sense is an effective way to ensure product processing quality.

And precision nc parts processing error, in fact, is the reflection of the comprehensive error of the machining system, which not only includes the manufacturing error of the fixture, but also includes the error of the machine tool, tool error, workpiece positioning error.In terms of the composition of the error and the controllability of the error, it is very important to study the error of the fixture.

In order to ensure the quality of product processing, precision CNC parts processing error control in a reasonable range, fixture wear to a certain degree must be repaired or scrapped, now we will understand the formation of manufacturing errors and how to adjust the jig.The manufacturing error of the fixture is composed of allowable error, shape error, limit deviation of the tool device, limit deviation of the feeler, limit deviation of the fixture positioning surface, and comprehensive error of the drill sleeve shaft and bushing hole.

Fixture wear, we generally from the following three aspects of adjustment:

1. Too big manufacturing error of fixture.We want to minimize manufacturing errors where possible;

2. When the fixture structure design is not reasonable, the fixture structure needs to be changed reasonably.

3. The size deviation of parts is too small.Negotiate with design and process personnel where possible to increase the size deviation of parts.

Precision nc machining error is the comprehensive reflection of machining system error.The practical synthetic error formula has certain reference value to production practice.The distribution of fixture wear limit deviation should consider the comprehensive factors such as wear resistance and importance of fixture parts.