What are the outstanding advantages of Weihua Technology as a supplier of stamping hardware?

Huizhou Weihua Technology Co., Ltd. (the factory is located in Dongjiang High-tech Zone, Shuikou Town, Huizhou City, with a plant area of 45000m² and nearly 1200 employees) is a leading brand in the domestic hardware industry. It has over 27 years of experience in stamping parts production. After years of hard work, it has developed into a comprehensive production enterprise integrating R&D, design, production, operation and sales.

What are the advantages of Weihua Technology's stamping hardware?

(1) Our stamping processing operation is convenient, easy to complete mechanization and automation. This is because our stamping relies on punching dies and stamping equipment to complete the processing. Generally, the number of strokes of the press is dozens of ups and downs per minute, and the high-speed pressure needs to be hundreds or even thousands of times per minute, and each stamping stroke is possible Get a stamped part.

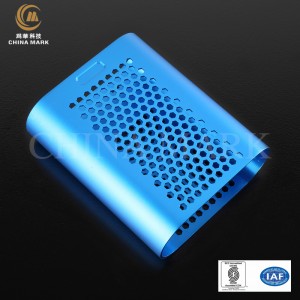

(2) Metal stamping can process parts with exquisite design and complicated shapes, as well as large-size parts, such as small rivets, cap nails, etc., to automobile longitudinal beams, covering parts, etc.

(3) During the stamping process, since the surface of the material is not damaged, it has a good surface quality and a smooth and beautiful appearance, which provides convenient conditions for surface painting, electroplating, phosphating and other surface treatments.

What advanced stamping machine does Weihua Technology have?

Our stamping equipment mainly includes various types of mechanical presses, stamping hydraulic presses, CNC punching, cutting machine tools and automation devices, among which high-quality continuous hydraulic presses have gradually become a new generation of stamping equipment for our sheet metal stamping production.

What materials can we use to make hardware signs?

Most use metal plates, especially carbon steel plates, stainless steel plates, aluminum plates, nickel plates, copper plates and zinc plates.

Which molds does Weihua Technology generally use to produce hardware signs?

Mainly include stamping die, bending die, drawing die, forming die, riveting die