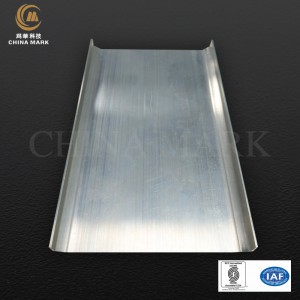

Extrusions aluminum,extrusion aluminum,extrusions aluminium case

How to choose post-processing for aluminum extrusion enclosures? These steps make the product instantly high-end!

1. CNC Machining

The extruded profile may lack precision in some details, and that’s where CNC comes in! Using precision machine tools for milling and drilling, it trims interfaces, grooves, and other parts to be neat and seamless—absolutely perfect! Things like mounting holes and step positions on equipment enclosures are all handled by CNC.

2. Sandblasting

Is the surface a bit rough? Arrange for sandblasting! High-speed sand particles impact the surface, creating a uniform matte texture that feels slightly gritty to the touch. It can also cover up small flaws, instantly enhancing the high-end feel!

3. Anodizing

This one deserves a special mention! After anodizing, the aluminum enclosure’s hardness skyrockets, and it becomes corrosion-resistant and scratch-resistant—it’s like a “golden bell shield” buff! The key is that it can be dyed in various colors! Silver and black are the most classic, but you can also get gold, red, etc. The appearance is directly maximized, and it’s not afraid of wind, sun, or rain even when used outdoors!

4. Other bonus items :

Brushing:Can create straight or chaotic lines, full of a techy vibe.

Laser Engraving: Engraves words or patterns on the surface, making logos and such super clear.

Passivation: A simple anti-oxidation treatment, suitable for parts with low appearance requirements.

In short, aluminum extrusion plus appropriate post-processing can make the enclosure both beautiful and durable!

If you guys see aluminum enclosure products with amazing texture, they’ve probably gone through these steps!

If you want this type of product too, feel free to contact us.