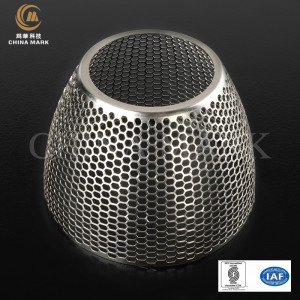

Precision metal stamping parts manufacturers custom - precision stamping parts processing customized for science and technology of China (China precision metal stamping manufacturer) there are many different kinds of precision stamping parts, large output, high precision and complex shape, the use of sheet materials, specializing in stainless steel stamping parts, copper stampings, aluminum and other metal stamping parts processing, welcome to figure to be customized

How do metal stamping parts and precision drawing parts manufacturers choose stamping materials?

Metal materials (including ferrous and nonferrous metals) are the most commonly used materials in the production of metal stamping and precision drawing parts, but sometimes nonmetallic materials are also used.

Among them, the ferrous metals mainly include ordinary carbon structural steel, high-quality carbon structural steel, alloy structural steel, carbon tool steel, stainless steel, electrical silicon steel, etc.

Non-ferrous metals are mainly pure copper, brass, bronze, aluminum, etc.Metal materials and models are many;

How do we choose the material, to achieve the workpiece quality assurance, and can save the purpose of materials?

Metal stamping parts manufacturers choose to stretch stamping materials generally have the following principles:

Metal materials must meet the performance requirements of the workpiece;The stamping parts work normally in the machine or parts and have a certain service life.

The selected material must have good technological performance;For any type of stamping piece, the selected material shall be able to meet the requirements of the stamping process.

The selected materials should have better economy;Materials should meet the requirements of performance and precision stamping process, as low as possible, convenient source, good economy, in order to reduce the cost of precision metal stamping parts.