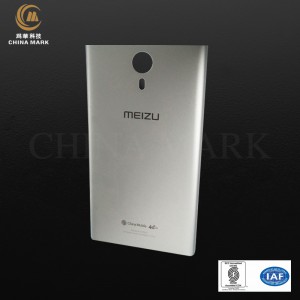

Precision CNC Machining,Extrusion,Anodized,Finished Edge | CHINA MARK

If you are interested in getting in touch with a our sales rep click here

The main process shows as below

Step A:Extrusion machine

Step B:CNC machine

Step C:Auto sand-blasting machine

Step D:Triangle grained machine

Step E:Anodic line

Step F:Hi-gloss drill,cut machine

Step G:Engraving machine

“Our 40,000 square meters facility has the capabilities to meet all your extrusion aluminum, logo plates,precision stamping needs coupled with multiple fabrication options to produce high-quality products solutions. ”

― WEIHUA

Write your message here and send it to us