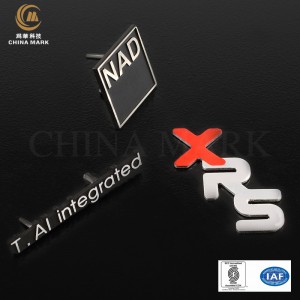

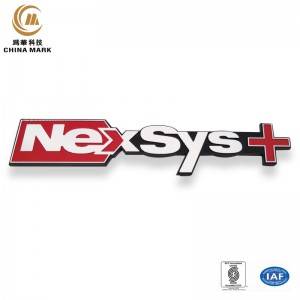

New Arrival China China Membrane Panel with Colorful Printing Faceplate, Name Plates & Speaker Grills

To create far more benefit for customers is our company philosophy; customer growing is our working chase for New Arrival China China Membrane Panel with Colorful Printing Faceplate, Name Plates & Speaker Grills, The team of our firm together with the use of cutting-edge technologies delivers impeccable quality merchandise supremely adored and appreciated by our prospects around the world.

To create far more benefit for customers is our company philosophy; customer growing is our working chase for China Touch Panel, Custom Badges & Nameplates, Labels and Nameplates, Musical Nameplates, Tags, We put the product quality and customer’s benefits to the first place. Our experienced salesmen supply prompt and efficient service. Quality control group make sure the best quality. We believe quality comes from detail. If you have demand, let us work together to get success.

Industrial nameplate inc

| Material | usually use the annealed alum |

| Process | -Alum cut+forge+stamp+anadize+rubberize-to get every kind of LOGO

-by cold forging process, -further combined with painting or anodizing, -and using diamond tools to get the carving finish or CD grain. , |

| Application | Nameplate for speaker |

| NW | 13g |

| Mold | Tool opening |

| LT | 15 days |

| Type | OEM Parts |

| Mass production Lead time | 4weeks |

Aluminum logo, copper name plates, fine process, fast proofing speed, support customer customization, product variety diversification, quality after-sales service. Welcome new and old customers to inquire ~

Surface protection method of metal nameplate

After the completion of the production of metal nameplate through the inspection, the first to pay attention to the metal nameplate packaging protection, to avoid in the process of transportation or use of the metal nameplate surface content scratch, scratch, damage paint, fade, bump and other phenomena.

Metal nameplate in addition to the pretreatment to do adequate protection preparation, the protection of the details of the later can not be ignored.How to fully protect the product surface, so that the high-end metal nameplate product surface is not affected?The following is a brief description of several surface protection methods:

Protective film method:

Some corrosion, engraving, stamping, printing, electroplating, high-gloss wire-drawing metal nameplate products, before the finished product packaging we will use the method of composite protective film, to avoid scratches caused by surface bumping.Usually use electrostatic film, PE protective film, according to the actual requirements of the product to choose the plastic film low, medium, high viscosity.

Packaging protection law:

In order to prevent the metal nameplate surface scratch, friction between products fade, the use of sealing packaging bags or opp plastic bags and other packaging protection.

Pearl cotton protection law:

For some metal nameplate products with fine surface quality or larger specifications, we use pearl cotton to package the products one by one to prevent scratching the surface during transportation.

You may also like:nameplate for speaker;Please click to view ~

![]()

If you are interested in getting in touch with a our sales rep click here

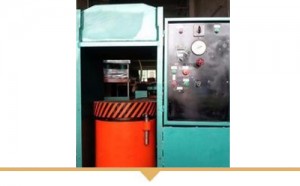

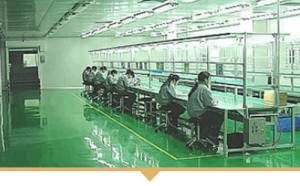

The main process shows as below

Step 1:Alum plate

Step 2:Laser cut according to engineering dwg

Step 3:Air-driven punching machine

Step 4:Forging device

Step 7:Exquisite nameplate

Step 5:Auto line of anodic oxide processing

Step 8:Professional inspectors and packaging workers

Step 6:Auto oil-dripping machine

“Our 40,000 square meters facility has the capabilities to meet all your extrusion aluminum, logo plates,precision stamping needs coupled with multiple fabrication options to produce high-quality products solutions. ”

― WEIHUA