factory low price China Powder Coating Cabinet Handle Aluminum Alloy Die Casting Fittings,Die Cast Plating Knob

“Control the standard by the details, show the energy by quality”. Our corporation has strived to establish a hugely efficient and stable workers team and explored an effective high quality control procedure for factory low price China Powder Coating Cabinet Handle Aluminum Alloy Die Casting Fittings,Die Cast Plating Knob, We honor our core principal of Honesty in business, priority in company and will do our greatest to provide our customers with high-quality goods and fantastic provider.

“Control the standard by the details, show the energy by quality”. Our corporation has strived to establish a hugely efficient and stable workers team and explored an effective high quality control procedure for China Cabinet Handle, Door Knob, Microwave Metal Stainless Steel Knob, Item have passed by means of the national qualified certification and been well received in our main industry. Our expert engineering team will often be ready to serve you for consultation and feedback. We have been able to also deliver you with cost-free samples to meet your specs. Ideal efforts will probably be produced to deliver you the most beneficial service and solutions. Should really you be interested in our company and solutions, please make contact with us by sending us emails or call us straight away. To be able to know our solutions and enterprise. ar more, you’ll be able to come to our factory to see it. We will constantly welcome guests from all over the world to our firm. o build business enterprise. elations with us. You should feel absolutely free to speak to us for organization. nd we believe we are going to share the best trading practical experience with all our merchants.

Cast nameplates,Etched logos

| Material | zinc alloy, alum alloy |

| Process | - Zinc alloy+dissolve+diecast+galvanized+ovening

- by die-cast by die-cast machine - further combined with polishing/galvanizing or painting process to achieve the parts.

|

| Application | Nameplate for induction cooker |

| NW | 150g |

| Mold | Tool opening |

| LT | 15 days |

| Type | OEM Parts |

| Mass production Lead time | 4weeks |

Weihua technology (embossed metal name plates manufacturers) is committed to providing customers with a variety of signage production (three-dimensional, aluminum, new metal, copper, zinc alloy, drop plastic nameplate, die-casting nameplate, high-grade alloy, electrocasting, hardware signage), welcome to inquire!

Casting nameplate: concave and convex, three-dimensional sense, often used in heavy equipment or equipment working in corrosive medium ~

Made by casting and made of metal;

Features of the cast nameplate:

| Plate type | Characteristics | Application | ||

| cast nameplate | metal | It is concave and convex, with a three-dimensional sense, mold processing, should be mass production, for 5mm below the handwriting performance is poor; | Vehicle license plates, heating appliances, stoves, etc | |

| plastic | Can be made into high – dimensional graphics and text, can be secondary decorative processing, injection molding or pressing from the mold | Three-dimensional trademark, chemical anticorrosion equipment | ||

Performance Features:

The depth of characters and symbols is large, and the durability is long.

What are the common metal nameplate manufacturing processes?

Nameplate refers to the sign with words, patterns and other contents used to indicate the direction and play a warning role.Common signs are metal signs, acrylic signs, PVC signs, copper signs, etc.Sign-making techniques are also varied,

The most common are the following:

One, screen printing nameplate

Sign making acrylic material sign making process to silk-screen more focus on the acrylic silk-screen printing process.

First the acrylic screen printing plate above the ink into.Then use acrylic scraping scraping board in the screen printing plate on the ink part of a certain pressure, at the same time to the screen printing plate on the other end of the average translation, ink in the translation process from the need to print the acrylic part of the picture and text mesh extrusion acrylic products.

Make use of the ink sticky action imprinting fixed on the required area.Again when the acrylic scraping board across the whole acrylic products layout, lift the acrylic screen printing plate will also lift.Finally, the ink will be lightly scraped back to the original position.

Two, sandblast sign:

With the computer engraving method, will be engraved post-it paste on the metal plate, the text graphics for sandblasting to form a sand-surface effect, and then carry out oxidation treatment, so that the metal plate appears on the effect of gold;

Three, etching the name plate filled with lacquer

In the process of plate making, metal etching is to cover the parts that need to be protected on the substrate with screen printing or screen printing, and then to use chemical or electrochemical methods to erode away the parts that are not needed, and finally to cover the protective film with different colors of paint.

Metal oxidation nameplate

The anodic oxidation of aluminum tube is generally carried out in an acidic electrolyte, with aluminum as the anode. In the electrolysis process, the anion of oxygen interacts with aluminum to produce an oxide film.This membrane is not dense enough at the beginning of formation. Although it has certain resistance, the negative oxygen ions in the electrolyte can still reach the surface of the aluminum and continue to form an oxide film.

As the film thickness increases, the resistance also increases, and the electrolytic current decreases.The outer oxide film in contact with the electrolyte then dissolves chemically.When the rate of oxide formation on the aluminum surface gradually balances with the rate of chemical dissolution, the oxide film reaches the maximum thickness for this electrolytic parameter.

Aluminum anodized film layer porous, easy to absorb dyes and colored substances, so it can be stained, improve its decorative.After the oxidation film is sealed by hot water, high temperature steam or nickel salt, its corrosion resistance and wear resistance can be further improved.

In addition to aluminum, there are magnesium alloy, copper and copper alloy, zinc and zinc alloy, steel, cadmium, tantalum, zirconium and so on.

V. plating nameplate:

It is the use of screen printing or photosensitive plate-making method, the metal plate coated with film, and then the use of electroplating method, so that the text and line through pre-plating, casting copper, nickel plating, gold-plated forming a raised pile of gold brand.

It can according to the user’s requirements to complete different patterns and a variety of font text, the product durable not corrosion, not afraid of the rain hit the sun, wear resistance, do not fade;

Its advantage is: beautiful and generous colour and lustre is bright-coloured, the design is clear, the brightness is good is all sorts of electronic products, the car, the household appliance and so on essential car body label to stick the nameplate brand;

You may also like:nameplate for oven;Please click to view ~

People also ask

What are the types and characteristics of nameplate logo?

What is the metal nameplate?What are the USES of metal nameplates?

![]()

If you are interested in getting in touch with a our sales rep click here

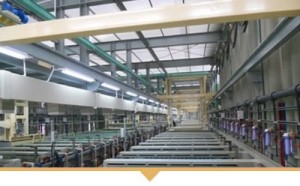

The main process shows as below

Step 1:Zinc alloy

Step 2:Advanced dissolved device

Step 3:Hi-precision die-cast tooling

Step 4:Large scale die-cast device

Step 7:Professional inspectors and packaging workers

Step 5:Galvanizing line

Step 8:Structured parts

Step 6:Industry oven, hi temp, low temp, constant temp

“Our 40,000 square meters facility has the capabilities to meet all your extrusion aluminum, logo plates,precision stamping needs coupled with multiple fabrication options to produce high-quality products solutions. ”

― WEIHUA