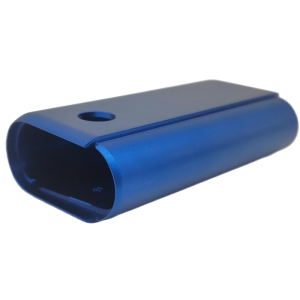

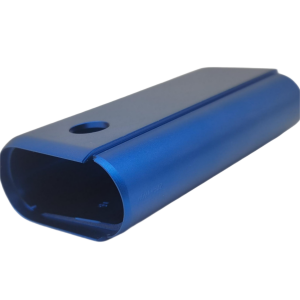

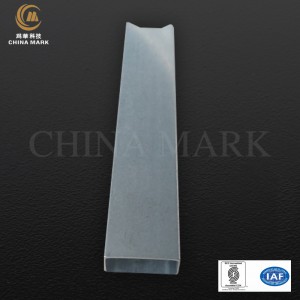

Extruded aluminium,extruded aluminum,aluminium extrusions case

As a common aluminum forming method, the aluminum extrusion process has unique advantages but also certain limitations.

Its specific advantages are as follows:

Advantages:

1.High forming efficiency, suitable for mass production: The aluminum extrusion process shapes a specific cross-section in one go through a mold, with strong continuous production capacity. It is particularly suitable for mass manufacturing of profiles with the same cross-section (such as housings, frames, etc.), which can quickly meet the needs of large-scale orders, and the production cycle is relatively short.

2.High material utilization rate, controllable cost: Compared with cutting processes (such as direct CNC milling forming), aluminum extrusion hardly generates a large amount of waste, and the raw material utilization rate can reach more than 90%, which can effectively reduce material costs. At the same time, once the mold is completed, the marginal cost of subsequent production is low, making it suitable for medium and large batch production.

3.Able to realize complex cross-sectional designs: As long as the cross-sectional shape can be designed in the mold (such as special-shaped, hollow, multi-cavity structures), aluminum extrusion can form it in one go. It is especially suitable for products that require an integrated structure (such as electronic equipment housings, heat dissipation profiles), reducing subsequent assembly steps and improving structural stability.

4.Superior mechanical properties of profiles: During the aluminum extrusion process, the internal grains of the aluminum material are elongated to form a fibrous structure, which improves the longitudinal strength and toughness of the profile. Its bending resistance and impact resistance are better than cast or rolled aluminum materials, making it suitable for scenarios with requirements on structural strength.

5.Strong compatibility with subsequent processing: Aluminum extruded profiles can be directly subjected to CNC precision processing (drilling, milling grooves, etc.) and surface treatment (sandblasting, anodizing, etc.), which can flexibly meet different functional and appearance requirements, and easily realize the combined scheme of “forming + refined processing”.

Summary:Aluminum extrusion processing is suitable for products with large batches, fixed cross-sections, cost sensitivity, and the need for an integrated structure (such as electronic housings, heat dissipation profiles, industrial frames, etc.).

However, for scenarios with small batches, ultra-complex precision requirements, or special materials (such as high-hardness aluminum alloys), it is necessary to balance the mold cost and subsequent processing costs. In practical applications, the combination of “aluminum extrusion + CNC + surface treatment” is often used to balance efficiency, cost, and performance~