Top Suppliers Wear Resistant Stainless Steel Plate 316 nameplate

We believe in: Innovation is our soul and spirit. Top quality is our life. Purchaser need is our God for Top Suppliers Wear Resistant Stainless Steel Plate 316 nameplate, Should you be interested in almost any goods, remember to truly feel totally free to get in touch with us for further facts or be sure to deliver us email right, we will reply you in just 24 hrs as well as the finest quotation are going to be provided.

We believe in: Innovation is our soul and spirit. Top quality is our life. Purchaser need is our God for Stainless Steel Plate, Stainless Steel Plate316, Stainless Steel Sheet, Upon today, we’ve customers from all over the world, including USA, Russia, Spain, Italy, Singapore, Malaysia, Thailand, Poland, Iran and Iraq. The mission of our company is to provide the highest quality items with best price. We’re looking forward to doing business with you.

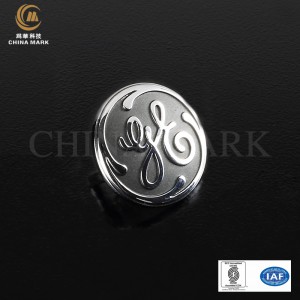

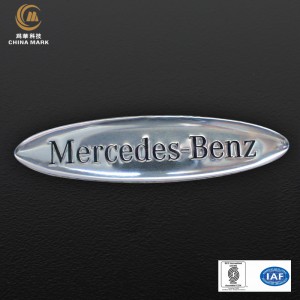

Engraved metal name plates

| Material | zinc alloy, alum alloy |

| Process | - Zinc+dissolve+diecast+galvanized+ovening - by die-cast by die-cast machine - further combined with polishing/galvanizing or painting process to achieve the parts.

|

| Application | Nameplate for bike |

| NW | 80g |

| Mold | Tool opening |

| LT | 15 days |

| Type | OEM Parts |

| Mass production Lead time | 4weeks |

Zinc alloy metal nameplate, high-quality nameplate manufacturers, advanced technology, reliable product quality, price concessions, material: aluminum, zinc alloy, stainless steel, copper;Widely used in: bicycle, luggage, luggage tags, medical equipment and other industries;Complete categories, manufacturers customized, cost-effective!Welcome to consult!

Shape of logo nameplate:

Metal plate mainly in copper, iron, aluminum, zinc alloy, pewter and other raw materials as the foundation, through the stamping, die-casting, etching, printing, enamel, imitation enamel, paint, such as technology, make nameplates, badges, badge, medal, key chain, cap badge, cap clip, wallet, MEDALS, commemorative COINS, craft signs, cufflinks, photo frames, mobile phone hang act the role ofing, tie clip, take the lead, tags, bottle opener, and other craft accessories and all kinds of metal plates, metal nameplate and so on different categories of all kinds of metal plates and plates processing products.

1. Horizontal nameplate: the whole ratio is relatively long.Generally the whole page is used as advertising signs.It can be seen on the walls of small shops and large buildings.

2, vertical signs: the whole proportion of vertical relatively long.Generally the whole page is used as advertising signs.

3, protruding nameplate: prominent in the building on the wall, in addition to the back of the whole face or there are two sides of the case of the wall are used as advertising carrier.

4. Ground-column nameplate: a horizontal, vertical or three-dimensional sign marking certain fixed structures on the ground.

5. Roof nameplate: refers to the plate-shaped square or phantom nameplate which is hung or attached to some fixed structures on the roof of a building.

![]()

If you are interested in getting in touch with a our sales rep click here

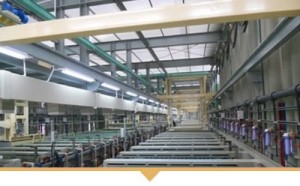

The main process shows as below

Step 1:Zinc alloy

Step 2:Advanced dissolved device

Step 3:Hi-precision die-cast tooling

Step 4:Large scale die-cast device

Step 7:Professional inspectors and packaging workers

Step 5:Galvanizing line

Step 8:Structured parts

Step 6:Industry oven, hi temp, low temp, constant temp

“Our 40,000 square meters facility has the capabilities to meet all your extrusion aluminum, logo plates,precision stamping needs coupled with multiple fabrication options to produce high-quality products solutions. ”

― WEIHUA