Professional China China Aluminium Metal Black Silk Printing Glossy Finish Anodized Plate,Engraved Logo

No matter new consumer or outdated shopper, We believe in lengthy expression and trusted relationship for Professional China China Aluminium Metal Black Silk Printing Glossy Finish Anodized Plate,Engraved Logo, Our goods are strictly inspected before exporting , So we gain a excellent reputation all over the world. We seeking forward to cooperation along with you within the long term.

No matter new consumer or outdated shopper, We believe in lengthy expression and trusted relationship for Aluminium Plate, anodized aluminum logo, China Gloss Aluminum Sheet, Custom Engraved Nameplate, They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it’s a have to for you of fantastic good quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We are confident that we’ve been gonna have a bright prospect and to be distributed all over the world in the years to come.

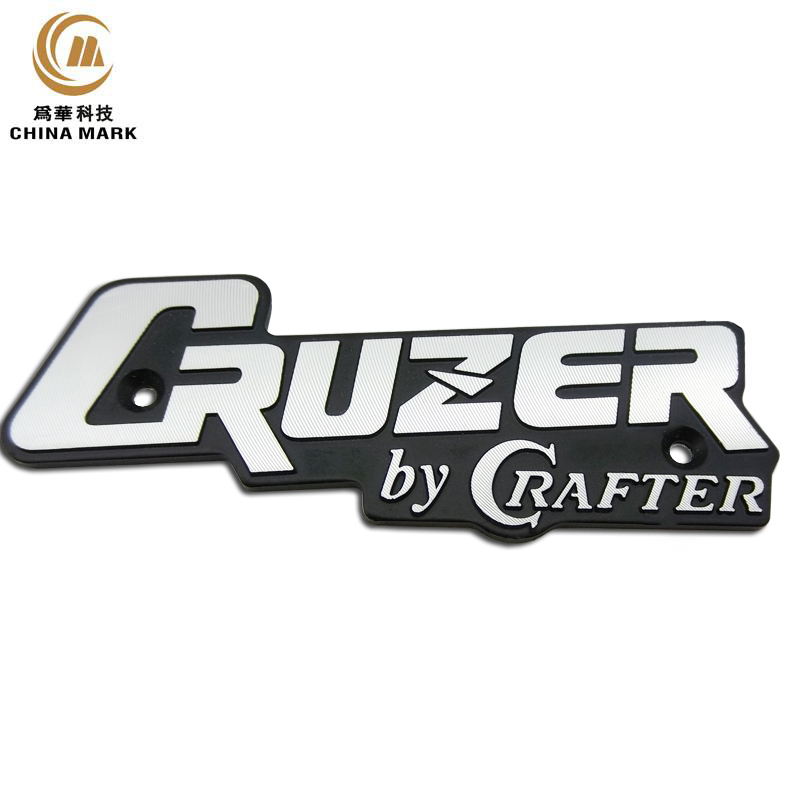

Choose custom metal logo signs for your company

If you’re looking to make a logo or other lettters & pattern displayed on a custom metal logo, Weihua technology can help. We’re leading brand metal sign fabrication factory in China and we’re experts at all kinds of nameplate & logo which involves alum-extrusion, CNC machining, engraving, painting or/and printing etc.

Stamping Aluminum Logo

| Type | Stamping nameplate |

| Process | Cutting+Stamping+Oil press+Blanking+Painting+Baking+High polished+Apply 3M9448 adhesive+Full inspection+Package |

| Application | Guitar nameplate |

For more details and information, please kindly check below content:

Q:What types of products do you mainly make ?

A: We mainly manufactures precise metal parts such as all kinds of custom metal logo & nameplate (aluminum logo, stainless steel logo and so on )which involves alum-extrusion, CNC machining, engraving, painting or/and printing etc

Q: Which kind of materials can be used to make custom signs ?

A: The material has various Stainless steel, iron, zinc alloy, brass, aluminum plate, aluminum profile etc.

Q:What are your main processing methods ?

A: it including stamping, forging, alum-extrusion, CNC, silkscreen printing, painting, plastic Injection etc;

Q: What are your main surface treatment methods ?

It including Sandblasting oxidation, UV, PU, painting & grinding, 3D laser-engraving, PVD,optical filming, CD wrinkle, drill carving, cropping , drawing, laser-engraving and so on.

Q: Can we get some free samples? Any charges?

A: Yes, you can get available samples in our stock. We can give free sample to you as long as you can pay shipping cost.

Q: How long can I get the samples?

A: Generally, it will only need 3-5 days to get your sample if don’t need open mold.And it will take about 6-10 days to get your sample if need mold open.

Q: Do you accept custom order?

A: Yes, off course. OEM service available and custom designs are very welcome.

Q :What is your minimum order quantity?

A: Our normal MOQ is 500pcs, small quantity is available for sample order but price will be high, please feel free to contact us to have a quote.

Q: Can we have our logo or company information to be printed on your products or package?

A: Yes, it is welcome.

Q: Can I order the logo with my logo and size?

A: Of course. Any shapes, any color, any size and any finishes is ok as lond as you send us 2D or 3D file for us.

Q: How do I place an order and what information should I provide when ordering?

A: Please email or call us to tell us below details:

Materials, shape, size, thickness, graphic, wording, finishes requested etc.

Send us your artwork file(design file) -2D/3D(PDF, AI, PSD, CDR, IGS etc) if you already have.

Requested quantity+EAU(estimated annual usage)

Contact details

Q: What is your lead-time?

A: It depends on the products. Normally, 5-10 workdays for samples, 12-18 workdays for mass production.

Q: What’s the trade and payment terms?

A: it will be 50% deposit before producing,then 50% balance before delivery. We accept T/T, Paypal, West Union etc.

Q: What shipping method can i choose? How about the shipping time of each option?

A: DHL, UPS, TNT, FEDEX, BY sea, etc. 3 to 5 workdays of express delivery. 10 to 30 workdays by sea.

![]()

If you are interested in getting in touch with a our sales rep click here

The main process shows as below

Step 1:St.St. plate

Step 2:Laser cut according to the engineering dwg

Step 3:Film or coating in the dust-free shop, light exposure imaging

Step 4:Etching, ie, remove material by way of chemical reaction or physical corrosion

Step 7:Industry oven, hi-temp, low-temp & constant temp.

Step 5:Get deepened by etching once, and texture finish by twice etching, like snow grain.

Step 8:Professional inspectors and packaging workers

Step 6:Done in the dust-free shop, by professional workers and advanced equipment

Step 9:Applied as precision etched parts for the electronic thin components for the aviation industry, machinery and chemical industry

“Our 40,000 square meters facility has the capabilities to meet all your extrusion aluminum, logo plates,precision stamping needs coupled with multiple fabrication options to produce high-quality products solutions. ”