ODM Supplier China Non-Standard Metal Components CNC Machining Service, suppliers precision stamping parts

The incredibly abundant projects administration experiences and 1 to one provider model make the superior importance of small business communication and our easy understanding of your expectations for ODM Supplier China Non-Standard Metal Components CNC Machining Service, suppliers precision stamping parts, should you have any query or wish to place an initial order please do not hesitate to contact us.

The incredibly abundant projects administration experiences and 1 to one provider model make the superior importance of small business communication and our easy understanding of your expectations for Aluminum Cnc Machining Computer Case, China Aluminium CNC Milling Machining Service, Meanwhile, we’re building up and consummating triangle market & strategic cooperation in order to achieve a multi-win trade supply chain to expand our market vertically and horizontally for a brighter prospects. development. Our philosophy is to create cost-effective merchandise, promote perfect services, cooperate for long-term and mutual benefits, firm a in depth mode of excellent suppliers system and marketing agents, brand strategic cooperation sales system.

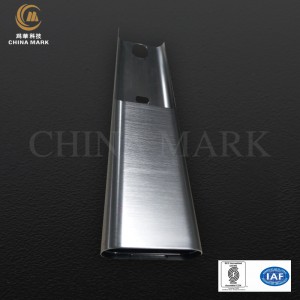

Precision Metal Stamping

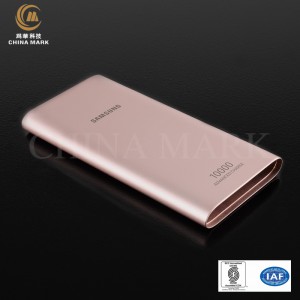

| Machines | Alum extrusion machine |

| Processing | - Alum extrusion+CNC+Anodized+Lase cutting. – further combined with the polishing/sand-blasting/graining to get the surface finish. – to get the protective layer by anodic oxide coating. – to get the high-gloss and cut/drill effect by hi-speed machine. – to get the logo by engraving. |

| Application | Charger pal products |

| NW | 30g |

| Mold | Alum extrusion Mold |

| Mold open cycle | 7 days |

| Type | OEM Parts |

| Mass production Lead time | 4weeks |

Weihua technology research and development around the direction of precision, multi-function, efficient, long life, with precision die stamping design, development, manufacturing capacity;

We specialize in precision forming and stamping.Precision stamping with its high quality and low price to win the favor of many customers, welcome to buy;

Advantages of precision stamping

1, stamping processing production efficiency, and easy to operate, easy to achieve mechanization and automation.This is because stamping is to rely on stamping die and stamping equipment to complete the processing, ordinary press stroke times for every minute up to dozens of times, high speed pressure to every minute up to hundreds or even thousands of times, and each stamping stroke may get a punch.

2, stamping because the mold to ensure the size and shape of the stamping parts precision, and generally do not destroy the surface quality of the stamping parts, and the mold life is generally long, so the quality of stamping stability, good interchangeability, with “exactly the same” characteristics.

3, stamping can be processed out of a larger size range, more complex shape of parts, such as small stopwatch, to the car longeron, covering parts, etc., plus stamping materials cold deformation hardening effect, stamping strength and stiffness are higher.

4, stamping generally no chip scrap material generation, material consumption is less, and do not need other heating equipment, so it is a kind of material saving, energy-saving processing method, stamping parts cost less.

![]()

If you are interested in getting in touch with a our sales rep click here

The main process shows as below

Step A:Extrusion machine

Step B:CNC machine

Step C:Auto sand-blasting machine

Step D:Triangle grained machine

Step E:Anodic line

Step F:Hi-gloss drill,cut machine

Step G:Engraving machine

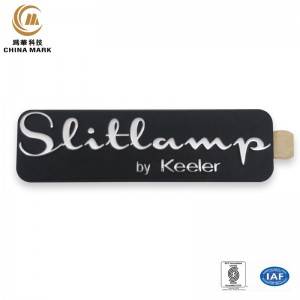

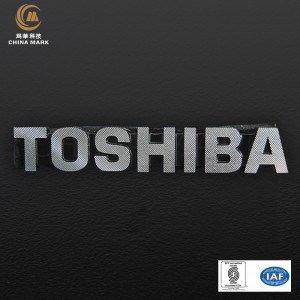

“Our 40,000 square meters facility has the capabilities to meet all your extrusion aluminum, logo plates,precision stamping needs coupled with multiple fabrication options to produce high-quality products solutions. ”

― WEIHUA