Manufacturing Companies for High Precision CNC Lathe Part Made in Huizhou

Our company sticks into the basic principle of “Quality is definitely the life of the business, and status may be the soul of it” for Manufacturing Companies for High Precision CNC Lathe Part Made in Huizhou, We welcome shoppers, enterprise associations and mates from all sections of your environment to call us and seek out cooperation for mutual advantages.

Our company sticks into the basic principle of “Quality is definitely the life of the business, and status may be the soul of it” for cnc lathe accessories, cnc precision part, Our company always committed to meet your quality demand, price points and sales target. Warmly welcome you open the boundaries of communication. It is our great pleasure to service you if you require a trusted supplier and value information.

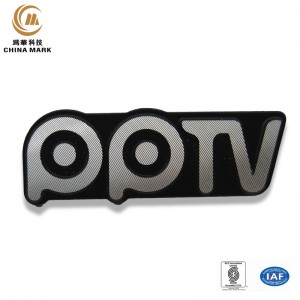

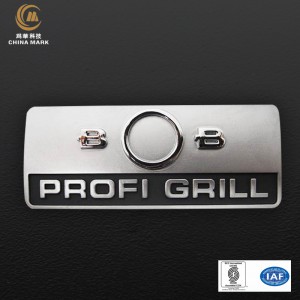

Precision Stamping Inc

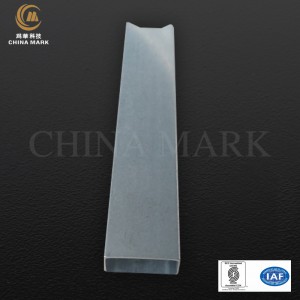

| Material | Alum extruded material or outsourced plate material |

| Processing | - copper rod +lathing&milling+ galvanizing.

- to get the protective layer by anodic oxide coating. - to realize the laser-engraved grid by laser-engraving process. |

| Application | |

| NW | |

| Tooling | |

| LT | |

| Type | OEM Parts |

| Mass production Lead time | 4weeks |

Weihua technology — China precision stamping company;Over 10 years of craftsmanship focus on precision forming and stamping, precision die metal stamping processing. The world’s top 500 partners, precision stamping parts precision up to ±0.01mm.Welcome to consult;

Design principles of precision stamping parts customization:

Precision stamping parts should be designed to meet the product performance and technical performance, and can be easy to assemble and repair.The following principles should be met;

(1) the design of precision stamping parts should be conducive to improving the utilization rate of metal materials, reducing the variety and specification of materials, and reducing the consumption of materials as far as possible.Use inexpensive materials where possible to make parts scrap free and scrap less blanking.

(2) the precision stamping parts design should be simple shape, reasonable structure, in order to help simplify the mould structure, simplify the process, which is the least, the most simple stamping process to complete the entire parts processing, reduce processing with other methods, and is advantageous to the stamping operations, is advantageous for the organization to realize mechanization and automation production, in order to improve labor productivity.

(3) the design of precision stamping parts should be conducive to using the existing equipment, process equipment and process flow to process them as far as possible, and is conducive to the extension of the service life of the punch.

![]()

If you are interested in getting in touch with a our sales rep click here

The main process shows as below

Step 1:Plate material

Step 2:CNC machine

Step 3:Auto sandblasting machine

Step 4:Hi-gloss drill,cut machine

Step 5:Plane grinding machine

Step 6:Anodic line

Step 7:Hi-gloss drill,cut machine

Step 8:Laser-engraving machine

“Our 40,000 square meters facility has the capabilities to meet all your extrusion aluminum, logo plates,precision stamping needs coupled with multiple fabrication options to produce high-quality products solutions. ”

― WEIHUA