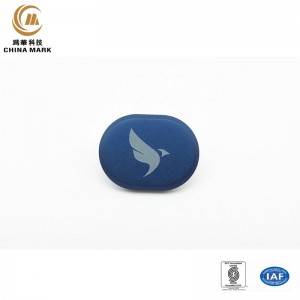

Manufacturer of China Precision Die Casting Aluminum Components with Precision CNC Machining

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate within our success for Manufacturer of China Precision Die Casting Aluminum Components with Precision CNC Machining, Because we stay within this line about 10 years. We got very best suppliers aid on quality and cost. And we had weed out suppliers with poor high-quality. Now lots of OEM factories cooperated with us too.

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate within our success for China Hardware, cnc 4 axis rotator, CNC Turning Metal Part, Precision cnc rotator, Spare Parts, As an experienced manufacturer we also accept customized order and we could make it the same as your picture or sample specification. The main goal of our company is to live a satisfactory memory to all the customers, and establish a long term business relationship with buyers and users all over the world.

What is precision machining?

In general, the machining method with machining accuracy between 0.1-1 m and machining surface roughness Ra between 0.02-0.1 m is called precision machining.

Precision machining belongs to the precision machining in the mechanical processing, according to the processed workpiece in the state of temperature, divided into cold processing and hot processing.

Generally under normal temperature processing, and does not cause the chemical or phase change of the workpiece, called cold processing.Generally in the above or below the normal temperature of the state of processing, will cause the chemical or phase change of the workpiece, called hot processing.Cold machining can be divided into cutting degree machining and pressure machining.Hot processing is commonly heat treatment, calcining, casting and welding.

What are precision machined components?

About the Industry The Precision Machined Products Industry consists of a diversified manufacturing base producing highly engineered machined components to customer specifications using a variety of materials such as steel, stainless steel, aluminum, brass, titanium, and aerospace and specialized alloys.

What industries use CNC?

CNC machining center is widely used in the current machining market and will definitely become a trend in the future.

Mainly do aluminum alloy parts for example can be used in the industry: hardware processing, mobile phone shell, auto parts, mold processing, and some manufacturers also need a lot of aluminum alloy parts such as machinery factory, environmental protection factory, connector factory, small processing shop, etc..

Details about Precision Machining

precision-machiningTo ensure the highest quality of the finished products, the use of computer programs is critical. CAD (Computer Aided Design) and CAM (Computer Aided Manufacturing) programs provide detailed blueprints about each step of the precision machining process. Precision machining can be used on many materials, including steel, aluminum, copper, bronze, and some special alloys.