Manufacturer for Precision Die And Stamping - Precision Stamping Parts,Lathe,Sandblasting,Laser Cutting | CHINA MARK – Weihua

Manufacturer for Precision Die And Stamping - Precision Stamping Parts,Lathe,Sandblasting,Laser Cutting | CHINA MARK – Weihua Detail:

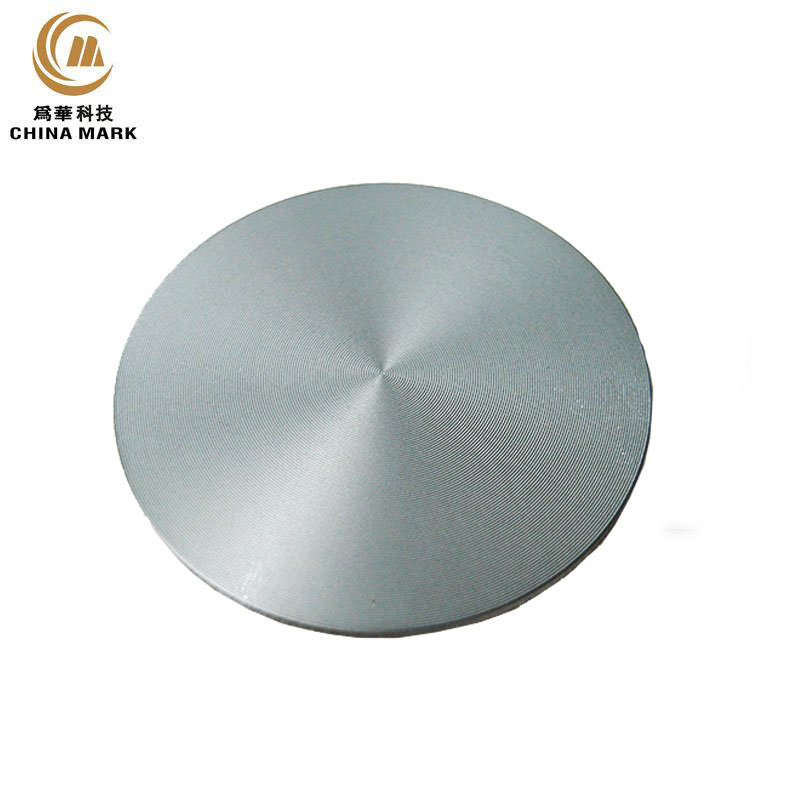

Precision Stamping Parts

| Machines | Alum extrusion machine |

| Processing | - Stamped+Lathe+Sandblasting+Laser cutting. - further combined with polishing/sand-blasting/grained to be the finish- to get the protective layer by anodic oxide coating - to get the logo by laser-engraving |

| Application | Teasaucer products |

| NW | 25g |

| Mold | Stamped mold |

| Mold open cycle | 8 days |

| Type | OEM Parts |

| Mass production Lead time | 4weeks |

Weihua is a precision die & stamping inc, specializing in the production of various precision metal stamping, stainless steel, aluminum stamping parts, metal stamping parts processing, and at the same time to provide customers with hardware die integrated solution.The product quality is superior, the price gives strength, sells well all over the world. Is the profession in the high quality choice. Welcome the new old customer to enter the company website the consultation!

What are the characteristics and precautions of precision stamping process?

Precision stamping process is a process method to obtain a certain size, shape and performance of the workpiece by applying external force to the blank through the die to produce plastic deformation or separation.The stamping process is widely used, which can be metal sheet material, bar material, or a variety of non-metallic materials.

I. characteristics of precision stamping process

(1) the workpiece with complex shape and difficult to be made by other methods, such as thin shell parts, can be obtained by cold stamping.

(2) the dimensional precision of cold stamping parts is guaranteed by the mold, so the dimensional stability and interchangeability are good.

(3) high material utilization, light weight, good rigidity, high strength, less energy consumption in stamping process.

(4) simple operation, low labor intensity, easy to achieve mechanization and automation.

(5) the die structure used in stamping is generally complex and the period is long.

Ii. Basic requirements of precision stamping materials:

The materials used for stamping should not only meet the technical requirements of the design, but also meet the requirements of the stamping process and the process requirements after stamping.The basic requirements of stamping process on materials are as follows:

(1) requirements on stamping forming performance: in order to facilitate the improvement of stamping deformation and product quality, the material should have good plasticity, small flexural strength ratio, large plate thickness directional coefficient, small plate plane directional coefficient, and small ratio of yield strength to elastic modulus of the material.For the separation process, the material does not need to have good plasticity, but it should have a certain amount of plasticity.The more plastic the material, the harder it is to separate.

(2) requirements for thickness tolerance of materials: the thickness tolerance of materials should meet the standard.Because a certain mold gap is suitable for a certain thickness of the material, the material thickness tolerance is too large, not only directly affect the quality of the parts, but also may lead to mold and punch damage.

Iii. Selection of precision stamping oil

(1) silicon steel plate is relatively easy to punching and cutting materials, generally in order to the workpiece finished products easy to clean, in the premise of preventing the emergence of punching and cutting burr will choose low viscosity stamping oil.

(2) carbon steel plate in the selection of stamping oil should pay attention to the first is the viscosity of the drawing oil.The optimum viscosity is determined according to the process difficulty and degreasing conditions.

(3) galvanized steel because of chemical reactions with chlorine additives, so in the selection of stamping oil should pay attention to the chlorine stamping oil may occur white rust, and the use of sulfur stamping oil can avoid the problem of rust, but after stamping should be degreased as soon as possible.

(4) stainless steel generally USES the stamping oil containing sulfur chloride compound additives, in order to ensure the extreme pressure performance, while avoiding the workpiece burr, rupture and other problems.

![]()

If you are interested in getting in touch with a our sales rep click here

The main process shows as below

Step A:Alum extrusion machine

Step B:Auto-lathing machine

Step C:CNC machine

Step D:Auto sand-blasting machine

Step E:Anodic line

Step F:Hi-gloss drill,cut machine

Step G:Laser-engraving machine

“Our 40,000 square meters facility has the capabilities to meet all your extrusion aluminum, logo plates,precision stamping needs coupled with multiple fabrication options to produce high-quality products solutions. ”

― WEIHUA

Product detail pictures:

Related Product Guide:

"Control the standard by the details, show the power by quality". Our firm has strived to establish a extremely efficient and stable employees crew and explored an effective excellent command method for Manufacturer for Precision Die And Stamping - Precision Stamping Parts,Lathe,Sandblasting,Laser Cutting | CHINA MARK – Weihua , The product will supply to all over the world, such as: Karachi, Czech republic, Turkmenistan, We will do our utmost to cooperate & satisfied with you relying on top-grade quality and competitive price and best after service ,sincerely look forward to cooperating with you and make achievements in the future!

The customer service staff's answer is very meticulous, the most important is that the product quality is very good, and packaged carefully, shipped quickly!