Hot Selling for China Watchcase/Watchband Magnetron Sputtering Coating Machine Case

We’ve a qualified, efficiency group to offer excellent support for our client. We normally follow the tenet of customer-oriented, details-focused for Hot Selling for China Watchcase/Watchband Magnetron Sputtering Coating Machine Case, We Sincerely welcome customers from all over the world to visit us, with our multifaceted cooperation and work together to develop new markets, create win-win brilliant future.

We’ve a qualified, efficiency group to offer excellent support for our client. We normally follow the tenet of customer-oriented, details-focused for China Magnetron Sputtering Coating Machine, Watchband Magnetron Sputtering Coating Machine, Due to the changing trends in this field, we involve ourselves into goods trade with dedicated efforts and managerial excellence. We maintain timely delivery schedules, innovative designs, quality and transparency for our customers. Our moto is to deliver quality solutions within stipulated time.

Spray painting plastic,Optical coating companies

| Material | ABS |

| Process | -Material prepare+moulding+deburr+grinding+galvanizing+ovening |

| Application | Electronic fan |

| NW | 15g |

| Mold | Tool opening |

| LT | 15 days |

| Type | OEM Parts |

| Mass production Lead time | 4weeks |

Optical vacuum coating, plastic spraying, plastic painting, plastic spraying – PU oil spraying, for China technology (optical coating companies);Ten thousand class dust-free workshop environment, plastic coating machine, automatic suction spraying, vacuum processing, product quality and quantity, optical coating technology, improve wear resistance, increase service life;Welcome to consult ~

Common plastic products spraying and vacuum coating surface treatment

1, spray painting

Plastic spray basically is to besmear on metal equipment or plastic product a layer of plastic paint, undertake coaxing again dry operation, general bake 10 minutes or so, benefit from the progress of paint, want to achieve the same effect, do not need to paste paper like before now.

Spray paint can play a role in isolating the air, spray paint is an insulator so it can play the role of anti-aging anti-static plastic products, the most important is to have the plastic products themselves do not have the appearance of the effect.

The effective method to solve the problem of poor adhesion between the substrate and the coating in the coating process of plastic surface is the kyongsheng adhesion promoter, which can improve the adhesion between the substrate and the coating to solve the problem of paint removal, with the adhesion up to 5B.

2. Vacuum optical coating

In the vacuum room, the atoms of the material are isolated from the heating source and hit to the surface of the plated object. This method can achieve a dazzling effect and is suitable for ABS and PC plastic products.At the same time, due to its complex process, environment, high equipment requirements, generally suitable for large quantities of products.

![]()

If you are interested in getting in touch with a our sales rep click here

The main process shows as below

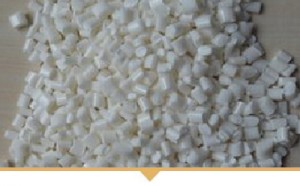

Step 1:ABS resin

Step 2:Molding machine

Step 3:Hi-precision tooling

Step 4:Galvanizing line

Step 7:Accessory for splendid toy

Step 5:Industry oven

Step 6:Full check lines

“Our 40,000 square meters facility has the capabilities to meet all your extrusion aluminum, logo plates,precision stamping needs coupled with multiple fabrication options to produce high-quality products solutions. ”

― WEIHUA