Factory supplied China Automatic Turntable Sandblaster Sandblasting Machine for CNC Metal Part

Adhering into the theory of “quality, services, efficiency and growth”, now we have gained trusts and praises from domestic and international shopper for Factory supplied China Automatic Turntable Sandblaster Sandblasting Machine for CNC Metal Part, We’re devoted to offer expert purification technology and solutions for you!

Adhering into the theory of “quality, services, efficiency and growth”, now we have gained trusts and praises from domestic and international shopper for Automatic Turntable Sand Blasting CNC Part, China Automatic Sand Blasting Machine, With the effort to keep pace with world’s trend, we will always endeavor to meet customers’ demands. If you want develop any other new solutions, we can customize them for yourself. If you feel interest in any of our goods or want develop new solutions, make sure you feel free to contact us. We’re looking forward to forming successful business relationship with customers all over the world.

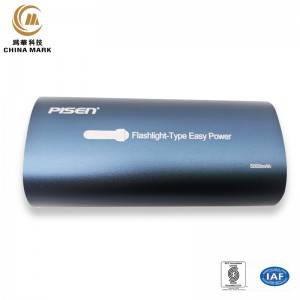

CNC Machining Precision Parts

| Machines | Alum extrusion +CNC+ Anodized + Polished machine |

| Processing | - Alum extrusion+Forging+CNC+Sandblasting+Laser cutting.- further combined with the polishing/sand-blasting/graining to get the surface finish.- to get the protective layer by anodic oxide coating.- to get the logo by laser engraving. |

| Application | Cell phone camera decorations |

| NW | 5g |

| Mold | Oil press mold |

| Mold open cycle | 12 days |

| Type | OEM Parts |

| Mass production Lead time | 4weeks |

Precision CNC parts processing - WEIHUA precision, the company has 5 axis automatic coordinate measuring instrument, 5 axis milling, multi-axis car, grinding machine, line cutting and other advanced processing equipment, batch processing, delivery time, high precision, good finish, after-sales perfect precision CNC parts processing welcome to inquire;

Advantages of precision metal stamping processing:

Precision stamping parts processing is through the punch and mold on the plate, strip, pipe and profile, such as the application of external forces, plastic deformation or separation, and then obtain the required shape and size of the workpiece forming processing method.

Precision stamping and casting are plastic processing (or pressure processing), collectively known as forging.The blanking stock is mainly hot and cold rolled steel plate and strip.

Compared with casting and forging, it has the characteristics of thin, even, light and strong.Precision stamping can produce parts with stiffeners, ribs, undulations or flanges that are difficult to produce by other methods to improve their rigidity.Due to the use of precision mold, the workpiece precision up to the micron level, and high repetition precision, specifications are the same, can be stamped out holes, boss, etc.

Cold stamping parts are generally no longer processed by cutting, or only a small amount of cutting.The precision and appearance of hot stamping parts are lower than that of cold stamping parts, but still better than castings and forgings.

Precision stamping is an efficient production method, the selection of composite die, especially multi-station progressive die, can be in a press machine to complete a number of stamping processes, from the strip uncoiling, leveling, blanking to forming, finishing automatic production.High production efficiency, good labor conditions, low production cost, generally hundreds of production per minute, greatly improve the production capacity.

![]()

If you are interested in getting in touch with a our sales rep click here

The main process shows as below

Step A:Oil-press machine

Step B:Punch machine

Step C:CNC machine

Step D:Auto sand-blasting machine

Step E:Anodized line

Step F:Hi-gloss drill,cut machine

Step G:Laser-engraving machine

“Our 40,000 square meters facility has the capabilities to meet all your extrusion aluminum, logo plates,precision stamping needs coupled with multiple fabrication options to produce high-quality products solutions. ”

― WEIHUA