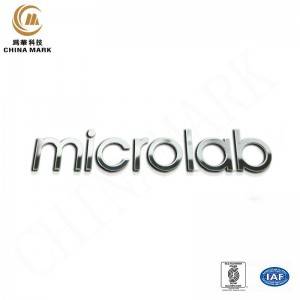

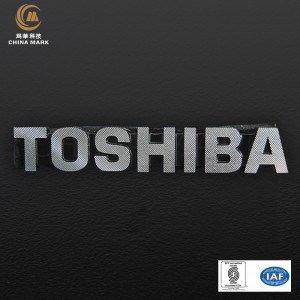

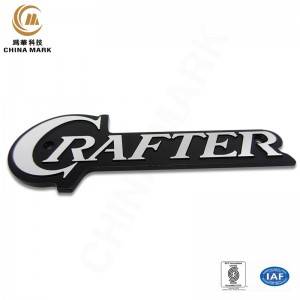

Factory source China Sound Diamond Plates,Engraved Audio name plate,Engraved Alum Name Plates

It truly is a great way to improve our merchandise and repair. Our mission should be to create imaginative products to prospects with a excellent knowledge for Factory source China Sound Diamond Plates,Engraved Audio name plate,Engraved Alum Name Plates, If you are hunting forever High quality at a good rate and timely delivery. Do get hold of us.

It truly is a great way to improve our merchandise and repair. Our mission should be to create imaginative products to prospects with a excellent knowledge for Black Anodized Tags, China Diamond Engraved Name Plates, Custom Speaker Engraved Name Badges, Our monthly output is more than 5000pcs. We’ve set up a strict quality control system. You should feel free to contact us for further information. We hope that we can establish long-term business relationships with you and carry out business on a mutually beneficial basis. We are and will be always trying our best to serve you.

Stamped metal name plates

| Type | Stamping diamond cutting nameplate |

| Process | Cutting+Stamping+Oil press+Blanking+Painting+Baking+High polished+Apply 3M9448 adhesive+Full inspection+Package |

Weihua techonlogy–Stamping workshop

![]()

If you are interested in getting in touch with a our sales rep click here

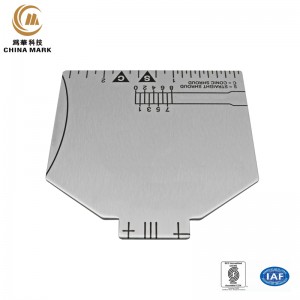

The main process shows as below

Step 1:St.St. plate

Step 2:Laser cut according to the engineering dwg

Step 3:Film or coating in the dust-free shop, light exposure imaging

Step 4:Etching, ie, remove material by way of chemical reaction or physical corrosion

Step 7:Industry oven, hi-temp, low-temp & constant temp.

Step 5:Get deepened by etching once, and texture finish by twice etching, like snow grain.

Step 8:Professional inspectors and packaging workers

Step 6:Done in the dust-free shop, by professional workers and advanced equipment