Factory For China Custom Self Adhesive Aluminum Sticker Label, Aluminum Label Metal Bar Signs for Home

We emphasize progress and introduce new solutions into the market each year for Factory For China Custom Self Adhesive Aluminum Sticker Label, Aluminum Label Metal Bar Signs for Home, We can give you the most competitive prices and high quality, because we are much more PROFESSIONAL! So please do not hesitate to contact us.

We emphasize progress and introduce new solutions into the market each year for China Aluminum Tags, Custom Metal Label, Stainless Steel Painting Logos, Zinc Plating Metal Nameplate, Most problems between suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question factors they do not understand. We break down people barriers to ensure you get what you want to the level you expect, when you want it. Faster delivery time and the product you want is our Criterion .

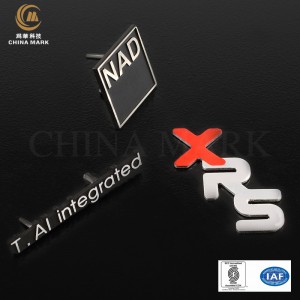

Custom decorative metal signs

| Material | zinc alloy, alum alloy |

| Process | - Zinc alloy+dissolve+diecast+galvanized+ovening+oiling+ovening - by die-cast by die-cast machine - further combined with polishing/galvanizing or painting process to achieve the parts.

|

| Application | Nameplate for electronic furnace |

| NW | 280g |

| Mold | Tool opening |

| LT | 15 days |

| Type | OEM Parts |

| Mass production Lead time | 4weeks |

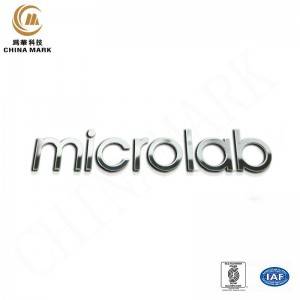

Weihua technology (plates with logo) super 10 focus on the metal nameplate customization and production, material: zinc alloy, aluminum, copper, stainless steel, brass, etc.Products are widely used in: induction cooker, luggage, medical, headset and other industries;To provide customers with personalized customized services for metal signs, rapid proofing, rapid response to customer demand, has successfully provided customized services for thousands of customers, a good brand is worth contacting!

Hardware nameplate process features:

Nameplates are divided into concave and convex nameplates and flat nameplates.

Ordinary die – casting nameplate, concave filled paint is nitrocellulose paint.The method of painting is to paint the entire front of the nameplate, and then remove the paint of the part of the font or pattern, exposing the metal literal or pattern lines.

The concave and convex nameplate of higher grade is coated with baking paint only, or partial besmear coloring paint, or besmear on transparent varnish, depend on the requirement completely and decide.

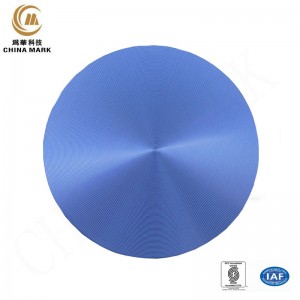

Planar nameplate is mainly made of aluminum alloy material, the color on its surface is not paint, but through anodic oxidation, stained to the color, according to the process method is different, can be monochrome, also can be 2-3 colors.

Flat nameplate has higher decorative performance, and the price is cheaper.Other screen printing nameplate, the color is ink;.

Imitation gold card: card color slant dim, a little longer time on the surface of the card is prone to fade, panting and other phenomena.

True gold card is also only at that time gold card color, time for a long time also lose true gold color.

Electrophoretic gold card: made with the latest technology, the color and luster is as bright as real gold.And can maintain the product will never fade the characteristic.

We provide stainless steel nameplate, brass name plate, aluminum name plate, engraved metal name plates, etc. Welcome to order!

You may also like:nameplate for bike;Please click to view ~

People also ask

What are the types and characteristics of nameplate logo?

![]()

If you are interested in getting in touch with a our sales rep click here

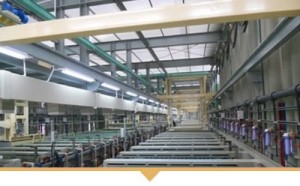

The main process shows as below

Step 1:Zinc alloy

Step 2:Advanced dissolved device

Step 3:Hi-precision die-cast tooling

Step 4:Large scale die-cast device

Step 7:Professional inspectors and packaging workers

Step 5:Galvanizing line

Step 8:Structured parts

Step 6:Industry oven, hi temp, low temp, constant temp

“Our 40,000 square meters facility has the capabilities to meet all your extrusion aluminum, logo plates,precision stamping needs coupled with multiple fabrication options to produce high-quality products solutions. ”

― WEIHUA