What are the product characteristics, development history and production process of the current etched metal nameplate? Weihua Technology, a professional custom metal nameplate manufacturer, collects some basic information and shares it with you.

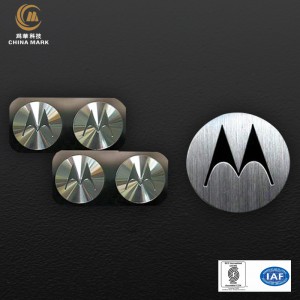

Etched nameplates (etched signs) are also called corroded metal nameplates. Mainly check embossed metal nameplates or indented metal nameplates that are processed by masking, etching, painting, and coloring.

Etched metal signs, introduction to metal nameplates

Etched nameplates are also called corroded metal nameplates. There are mainly embossed metal nameplates or indented metal nameplates made by cutting materials, preparing masks, etching, and post-processing.

Etching nameplate production principle

The main process is completed by the steps of cutting the board, preparing the mask layer, etching, fading, painting and coloring, polishing and varnishing.

Among them, there are several processes for mask preparation, namely, etching excellent version, silk screen, photosensitive, and engraving film.

Features of Etching Nameplate

It is durable and has a wide range of usage scenarios.

Etching nameplate development history

Etched nameplates have been made for a long time, ranging from machine tool nameplates to various signs and road signs.

Etching nameplate making process

1) Blanking: According to the size required by the drawing (page size), plus a burr of not less than 5mm on all sides. The 720 type foot-operated shearing machine is used for shearing, and the surface is required to be flat and there is no margin around it.

2) Surface treatment of metal corrosion nameplate:

(1) Mechanical polishing: Use a 2.2-4 kilowatt polishing machine to mechanically polish the wool. The cloth wheel uses a 300-350 motor with a rotation speed of 2000-3000 revolutions/min.

(2) Alkali treatment: Boil the metal plate with 10-15% sodium hydroxide in an aqueous solution at 65-85°C for 10-30 seconds, then wash it with clean water, and immerse it in a 5% bivalent acid aqueous solution.

(3) Powder treatment method: Use a flat brush with old powder (double powder) to scrub the ears with a uniform cross method until the stain is removed or the oxygen skin is removed, and then use 5% potassium dichromate aqueous solution In the closed.

(4) Wire-drawing treatment method: use mechanical or manual wire-drawing method to wire-draw the metal plate surface to achieve the metal surface regeneration effect.

The above relevant information about the etching nameplates hopes to bring you some useful sharing. At the same time, if you have relevant metal nameplate customization needs, you can contact us. Weihua Technology specializes in customizing metal nameplates, aluminum signs, etc.

If you want to know more about custom metal nameplates, please search “cm905.com“, we are a metal nameplate supplier from China, welcome to consult us!

We are here to serve you!

Custom metal logo plates - we have experienced and trained craftsmen who can produce reliable, high quality metal identification products using all types of finishes and materials used in today's businesses.We also have knowledgeable and helpful salespeople who are waiting to answer any questions you may have.We are here to help you make the best choice for your metal nameplate!

Post time: May-22-2021