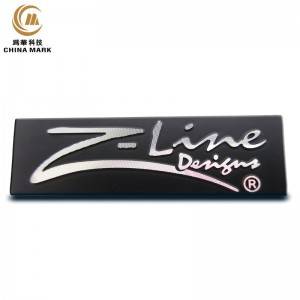

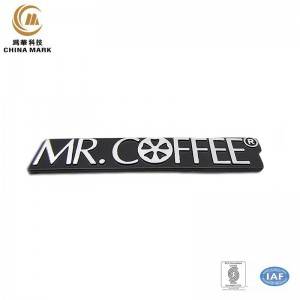

Aluminium lub npe phajyog ib qho ntawm ntau cov cim, feem ntau yog ua los ntawm aluminium tag stamping, txiav, concave thiab convex, thiab aluminium alloy tuag-casting. Cov txheej txheem nquag: siab dhau los (polishing), etching, oxidation, xaim hlau, laser engraving, electroplating, txau, ci varnish, tshuaj ntsuam luam ntawv thiab lwm yam txheej txheem. Ntau tus cim, lej, qauv, thiab lwm yam tuaj yeem luam tawm. Xyoo tsis ntev los no, kev kos npe rau aluminium tau siv dav hauv cov khoom siv hluav taws xob, khoom siv hluav taws xob, khoom siv tshuab, tshuab cua txias, TV, kua siv lead ua kua, siv taw qhia, tsheb, tsheb pib thiab maus taus, mopeds hluav taws xob, qhov rooj, qhov rooj ruaj ntseg, rooj tog, khoom siv hauv chav ua noj, chaw ua haujlwm cov khoom siv, thiab chav dej, Suab, lub nra, khoom siv, ntau lub thawv ntim cawv, ntim cov thawv ntim, lub hli ncuav mog qab zib ntim, khoom plig ntim khoom plig thiab lwm yam khoom LOGO.

Ntawm cov khoom lag luam ntawm cov paib hlau, cov paib txhuas cim rau ntau dua 90% ntawm cov cim hlau. Rau ntau tshaj ib nrab xyoo, cov cim ua los ntawm txhuas phaj tau ua siab ntev ntev. Lub ntsiab yog vim li cas hais tias txhuas muaj dai zoo nkauj. , Ntau txheej txheem kho kom zoo nkauj saum npoo av tuaj yeem thov thiab siv cov txheej txheem aluminium, uas yooj yim kom tau txais cov yeeb yuj thiab ntau qhov sib xyaw ua ke ntawm cov qib siab dai kom zoo nkauj. Ntawm qhov tod tes, nws yog txiav txim siab los ntawm cov xwm txheej ntawm cov khoom zoo kawg nkaus ntawm txhuas.

Qhov zoo ntawm kev siv txhuas ua cov paib ua raws li hauv qab no:

1. Lub teeb ceeb thawj. Qhov ntom ntom ntom ntawm txhuas yog 2.702gNaN3, uas tsuas yog 1/3 ntawm qhov ntawd tooj thiab tooj. Alib cov cim yuav tsis nce qhov hnyav ntawm cov cuab yeej thiab txuag nqi.

2. Nws yooj yim rau txheej txheem, aluminium muaj zoo ductility, yooj yim txiav, thiab yooj yim rau lub thwj, uas tuaj yeem ua tau raws li qhov xav tau ntawm cov txheej txheem tshwj xeeb rau cov paib.

3. Kev tiv thaiv zoo corrosion, zaj duab xis nyuaj thiab ntuag oxide tuaj yeem tsim rau saum npoo ntawm txhuas thiab nws cov hlau.

4. Cov huab cua zoo tiv thaiv, aluminium oxide zaj duab xis txheej, ntau yam tshuaj tsis ua rau xeb ntawm nws, thiab nws yuav muaj cov kav ntev zoo thaum siv rau hauv qhov chaw tsis zoo hauv thaj chaw muaj kev lag luam thiab ntug dej hiav txwv.

5. Tsis muaj lub zog sib nqus, aluminium tsis muaj hlau nplaum, thiab cov phiajcim txhuas yuav tsis ua rau sab nraud cuam tshuam rau cov khoom siv.

6. Cov nplua nuj nyob hauv cov peev txheej, qhov kev tsim tawm txhua xyoo ntawm txhuas yog qhov thib ob rau cov hlau, yog qeb thib ob hauv lub ntiaj teb cov hlau tas nrho.

Qhov zoo ntawm kev siv txhuas daim ntawv lo tsis tsuas yog ntau yam, tab sis cov txheej txheem ntau lawm tau dhau los ua ntau dua thiab paub tab.