Polishing na-ezo aka iji polishing wax, hemp wheel, nylon wheel, akwa wheel, wind wheel, waya ákwà wiil na ndị ọzọ polishing ngwaọrụ na abrasive ahụ ma ọ bụ ndị ọzọ polishing media iji gbanwee elu nke workpiece iji belata n'elu roughness nke workpiece. iji nweta na-egbuke egbuke , Usoro nhazi ihe eji achọ mma maka elu dị larịị.Usoro a nwere ike imeziwanye nguzogide corrosion na mmetụta na-egbuke egbuke nke igwe anaghị agba nchara.

Yabụ, kedu ụzọ a na-ejikarị igwe anaghị agba nchara polishing maka anyịụlọ ọrụ ahanandị na-emepụta aha aha igwe?

Nke a bụ ụzọ polishing anyị na-ahụkarị:

1 Mechanical polishing:

N'iji teknụzụ a, enwere ike nweta oke ike nke Ra0.008μm, nke kachasị elu n'etiti ụzọ polishing dị iche iche.

2 Chemical polishing:

Isi uru nke usoro a bụ na ọ dịghị achọ ngwá ọrụ dị mgbagwoju anya, nwere ike ime ka ihe ndị na-arụ ọrụ na-eme ka ọ dị mgbagwoju anya na-egbuke egbuke, ma nwee ike ịmegharị ọtụtụ workpieces n'otu oge, na-arụ ọrụ dị elu.Ọkpụkpụ elu enwetara na-abụkarị ọtụtụ μm 10, nke a na-ejikarị eme ihe n'ime ụdị polishing asaa.

3 Electrolytic polishing:

Ọ nwere ike iwepụ mmetụta nke mmeghachi omume cathodic, na mmetụta dị mma.N'otu oge ahụ, ọ nwere ike ịbawanye nguzogide corrosion nke igwe anaghị agba nchara, melite izi ezi nke ngwá ọrụ dị iche iche dị iche iche, ma mee ka ihe ndị dị mkpa na ígwè dị mkpa kwa ụbọchị dị mma na ihe ndị ọzọ. Ọ dabara maka ígwè, aluminum, ọla kọpa, nickel na ngwaahịa ndị ọzọ.Alloy polishing.

4 Ultrasonic polishing:

The macroscopic ike nke ultrasonic nhazi bụ obere, na ọ gaghị eme ka deformation nke workpiece.

5 Nchacha mmiri mmiri:

abrasive jet machining, mmiri mmiri jet machining, hydrodynamic egweri, wdg.

6. Magnetik egweri na polishing:

Usoro a nwere nhazi nhazi dị elu, ịdị mma dị mma, njikwa dị mfe nke ọnọdụ nhazi na ọnọdụ ọrụ dị mma.Ọdịiche dị n'elu nwere ike iru 0.1μm.

7. Chemical n'ibu polishing:

nwere ike nweta oke ala site na nanometer ruo ọkwa atọm.Ọzọkwa, mmetụta enyo na-egbuke egbuke nwere nnukwu nchapụta, enweghị mmejọ, yana ezigbo flatness.

Dị ka ya dị iche iche polishing akara ule, ọ nwere ike kewara n'ime ndị na-esonụ akara ule nke igwe anaghị agba nchara polishing ọkpọkọ:

1. Ọkwa ihie

E kewara ihe nchọpụta nchapụta n'ozuzu n'ime 2K, 5K, 8K, 10K, 12 mmetụta elu.Ọganihu dị elu, mmetụta dị elu ka mma na ọnụahịa dị elu.

Dị ka usoro nlele anya si dị, a na-ekewa nchapụta nke elu igwe anaghị agba nchara nchara n'ime akara 5:

Ọkwa 1: Enwere ihe nkiri oxide na-acha ọcha n'elu, enweghị nchapụta;

Ọkwa 2: Na-egbukepụ ntakịrị, enweghị ike ịhụ ndepụta ahụ nke ọma;

Ọkwa 3: Ìhè ka mma, a pụrụ ịhụ nkọwapụta;

Ọkwa 4: Elu na-egbuke egbuke, a pụkwara ịhụ ihe ndepụta ahụ n'ụzọ doro anya (dakọtara na elu elu nke electrochemical polishing);

Ọkwa 5: Nchapụta dịka enyo.

A na-ejikwa igwe anaghị agba nchara n'ọtụtụ ebe n'ihi nnukwu nguzogide corrosion na ihe ịchọ mma, karịsịa na ngwa ahụike, ngwa ụlọ ọrụ nri, tableware, ngwa kichin, wdg. Ọ na-ewu ewu ma kwalite.

Ọ bụrụ na ị nwere mmasị na ndị a ma chọọ ịmatakwu banyere yaka esi ehichaa efere aha, otu esi ehicha nọmba ụlọ ọla, Kedu ka esi enwu efere aha igwenaKedu ka esi ehicha ọla a kanyere akara, biko lelee anyị ukara website ịmụtakwu, ma ọ bụ kpọtụrụ anyị ahịa ndị ọrụ ozugbo.

Mụtakwuo maka ngwaahịa WEIHUA

Anyị bịara ebe a ijere gị ozi!

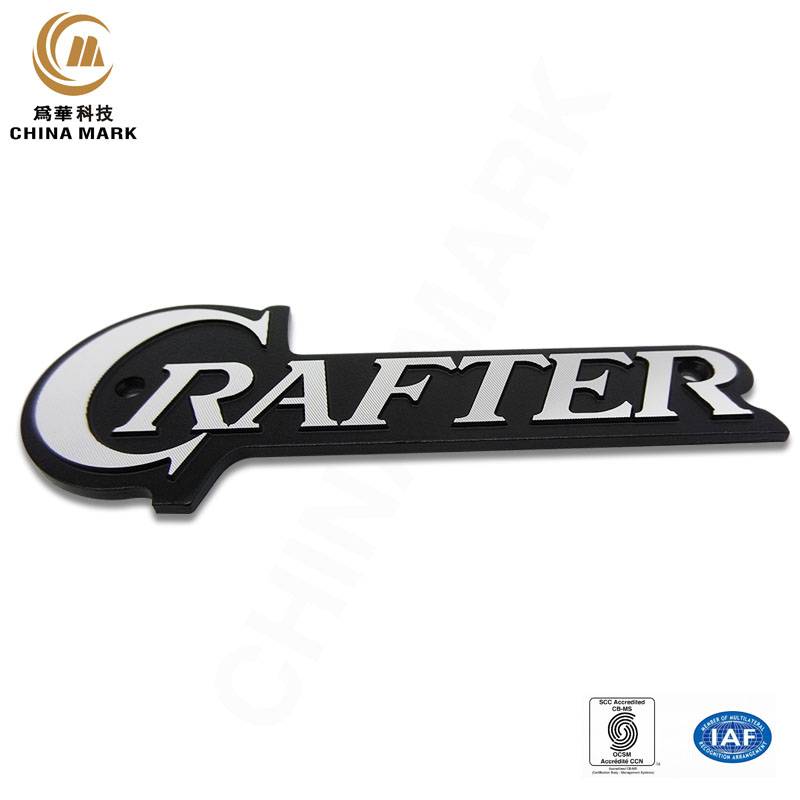

Efere akara ngosi ọla omenala- anyị nwere ahụmahụ na ndị omenkà zụrụ azụ ndị nwere ike ịmepụta ihe a pụrụ ịdabere na ya, ngwaahịa njirimara metal dị elu na-eji ụdị ihe ọ bụla emecha na ihe eji eme ihe n'ahịa taa. Anyị nwekwara ndị na-ere ahịa maara ihe ma na-enyere aka na-echere ịza ajụjụ ọ bụla ị nwere. Anyị nọ ebe a. iji nyere gị aka ime nhọrọ kacha mma maka gịigwe aha!

Oge nzipu: Eprel-07-2022